What Are CNC Machines? A Comprehensive Guide to Modern Precision Manufacturing

The question “what are CNC machines?” lies at the heart of today’s advanced manufacturing landscape. CNC (Computer Numerical Control) machines are automated systems that transform digital designs into physical components with micron-level accuracy. At JLYPT, we leverage these machines to craft mission-critical parts for industries where precision is non-negotiable—from jet engine turbines to life-saving medical implants.

This article answers “what are CNC machines?” by exploring their mechanics, evolution, and real-world applications, while highlighting JLYPT’s expertise in pushing this technology to its limits.

Defining CNC Machines: Beyond the Basics

When asking “what are CNC machines?”, the answer begins with their core function: computerized control of machining tools via pre-programmed software. Key components include:

-

Controller: Converts CAD files into G-code instructions (e.g., Siemens Sinumerik).

-

Drive System: Servo motors and ball screws achieve movements as precise as 0.001 mm.

-

Tooling: Multi-axis spindles and automatic changers (e.g., 120-tool magazines).

For instance, JLYPT’s 5-axis CNC mills produce Inconel 718 turbine blades with cooling channels thinner than a human hair (±0.002 mm).

The Evolution of CNC Technology

Understanding “what are CNC machines?” requires tracing their development:

-

1940s-50s: MIT’s punch-card systems for military helicopter parts.

-

1980s: CAD/CAM integration enabled 3D machining.

-

2020s: AI-driven CNC systems optimize toolpaths in real time.

JLYPT’s machines now use IoT sensors to predict tool wear, reducing scrap rates by 22% in aerospace projects.

How CNC Machines Work: A Step-by-Step Breakdown

-

Design: Engineers create 3D CAD models of components.

-

Programming: CAM software generates toolpaths and G-code.

-

Setup: Operators load materials (e.g., titanium billets) and tools (e.g., carbide end mills).

-

Machining: The CNC machine executes operations like milling, turning, or drilling.

-

Inspection: CMMs validate tolerances against original CAD data.

At JLYPT, this process is streamlined through AI-powered software that flags design flaws (e.g., undercuts) during quoting.

Industry Applications: Where CNC Machines Excel

1. Aerospace: Precision at Extreme Scales

-

Turbine Disks: Machined from powder metallurgy superalloys (René 88DT) to withstand 800°C.

-

Satellite Frames: Aluminum 7075-T651 structures with 0.005 mm positional accuracy.

2. Medical: Saving Lives with Accuracy

-

Knee Implants: CoCrMo alloy components polished to Ra 0.2 µm for reduced wear.

-

Surgical Drills: Stainless steel 440C tools with 0.01 mm flute consistency.

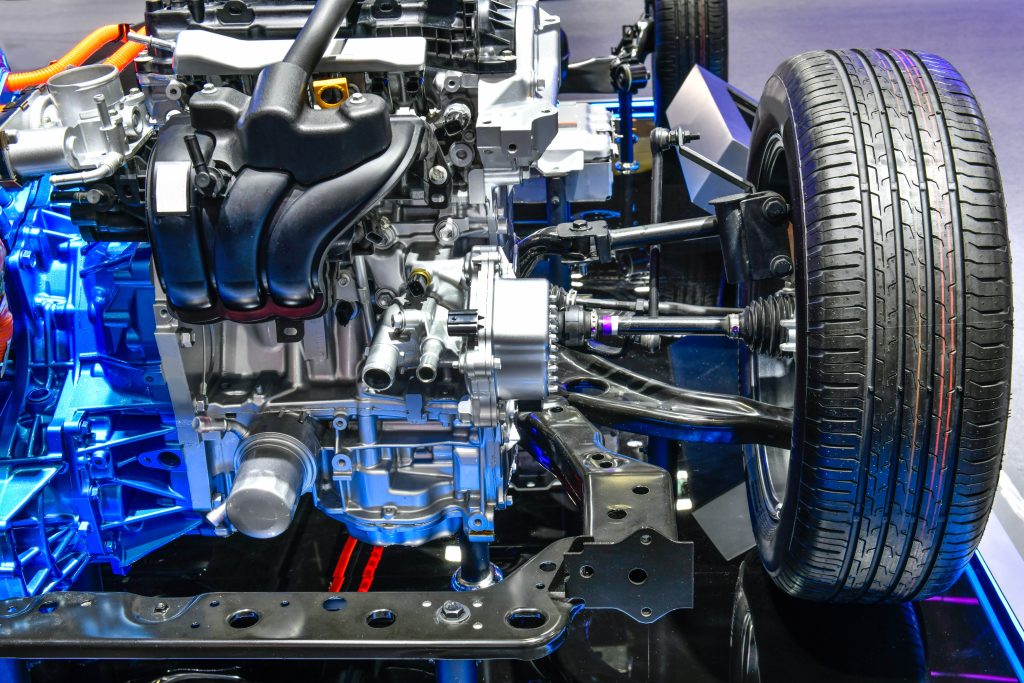

3. Automotive: Speed Without Compromise

-

EV Motor Housings: Waterjet-cut aluminum A356-T6 castings finished to IP68 standards.

-

Transmission Gears: Case-hardened 20MnCr5 steel with AGMA Q10 quality.

Technical Innovations in Modern CNC Machining

1. Multi-Axis Capabilities

-

5-Axis Simultaneous Machining: Create impellers with complex curvatures in one setup.

-

Swiss-Type Lathes: Machine Ø0.15 mm Nitinol wires for medical catheters.

2. Material Advancements

-

Superalloys: Inconel 625 for corrosive environments.

-

Composites: Carbon fiber-reinforced polymers (CFRP) for lightweight aerospace parts.

3. Sustainability Initiatives

-

Energy Recovery: Regenerative drives reduce power consumption by 30%.

-

Chip Recycling: 95% of titanium waste reused in new billets.

Case Study: Medical Device Breakthrough

Challenge: A client needed 1,000 spinal fusion cages (Ti-6Al-4V ELI) with porous surfaces (Ra < 0.8 µm) in 20 days.

JLYPT’s Solution:

-

Tooling: Diamond-coated ball end mills for uniform porosity.

-

Process: Adaptive stepover algorithms to maintain surface integrity.

-

Result: Delivered in 18 days, achieving 100% FDA compliance.

The Future of CNC Machines

Emerging trends redefining “what are CNC machines?”:

-

AI-Driven Optimization: Self-correcting toolpaths reduce cycle times by 15%.

-

Hybrid Manufacturing: Combine 3D printing and CNC finishing for complex geometries.

-

Nano-Machining: Achieve sub-micron tolerances for optical lenses.

Why Partner with JLYPT?

-

Certifications: AS9100 (aerospace), ISO 13485 (medical), IATF 16949 (automotive).

-

Global Network: Facilities in the EU, North America, and Asia ensure fast delivery.

-

Expert Support: DFM consultations reduce costs by 25% on average.

Conclusion: CNC Machines Defined Through Excellence

The question “what are CNC machines?” finds its answer in their ability to merge digital precision with material mastery. From their mid-20th-century origins to today’s AI-augmented systems, CNC technology continues to redefine manufacturing possibilities. At JLYPT, we harness this evolution to deliver components that power industries where failure is not an option.

Ready to experience CNC innovation? Contact JLYPT for a quote today.