What Does a CNC Machine Do? Unveiling the Engine of Modern Manufacturing

The question “what does a CNC machine do?” lies at the heart of today’s industrial innovation. CNC (Computer Numerical Control) machines are automated systems that transform digital designs into physical parts with microscopic precision. At JLYPT, we utilize these machines to craft components for jet engines, surgical robots, and electric vehicles—where tolerances as tight as ±0.002 mm separate success from failure. This article demystifies what a CNC machine does, its applications, and how JLYPT’s expertise pushes the boundaries of precision.

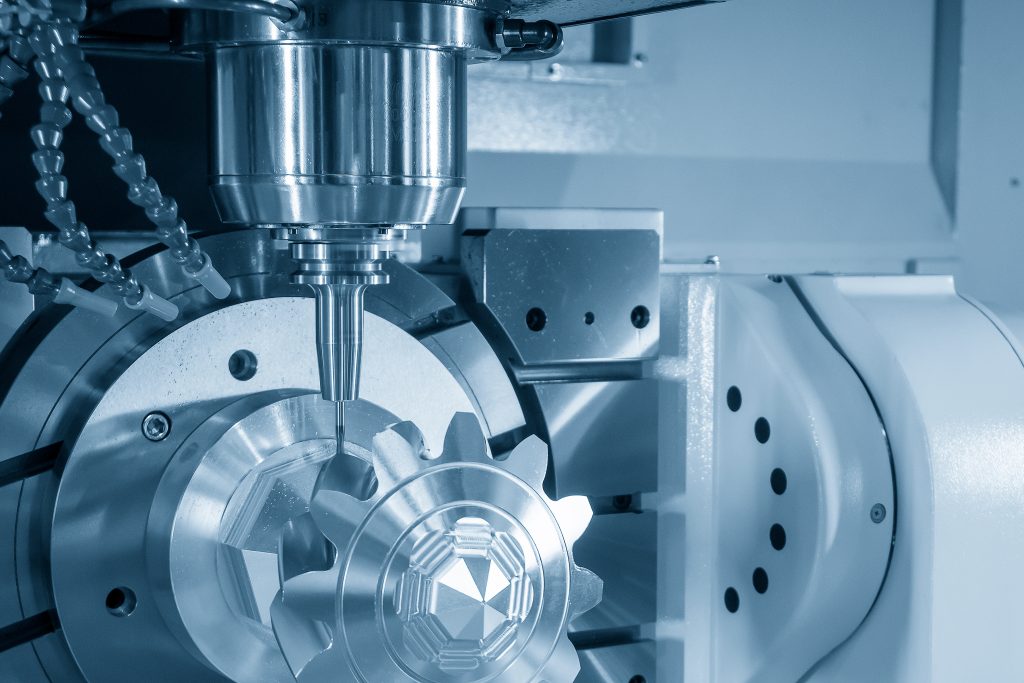

What Does a CNC Machine Do? Core Functions Explained

What does a CNC machine do? At its essence, it executes pre-programmed instructions to cut, drill, mill, or shape materials into precise components. Here’s how:

-

Digital Design Input: CAD files define the part’s geometry.

-

Code Conversion: CAM software translates designs into G-code (machine instructions).

-

Automated Machining: Tools like end mills or lathes remove material to form the part.

-

Quality Assurance: Probes and sensors validate dimensions during production.

For example, JLYPT’s 5-axis CNC mills carve titanium aerospace brackets with 0.005 mm accuracy—thinner than a human hair.

Key Operations: What Does a CNC Machine Do Daily?

-

Milling: Rotating tools carve complex shapes (e.g., aluminum engine blocks).

-

Turning: Lathes spin workpieces to create cylindrical parts (e.g., stainless steel shafts).

-

Drilling: Precise hole creation (e.g., coolant channels in turbine blades).

-

Grinding: Achieve ultra-smooth surfaces (e.g., Ra 0.1 µm on medical implants).

Industries Transformed by CNC Machines

1. Aerospace: Defying Extreme Conditions

-

Turbine Blades: Machined from Inconel 718 to endure 1,200°C and 15,000 RPM.

-

Satellite Frames: Aluminum 7075-T6 structures with 0.003 mm positional accuracy.

-

Case Study: JLYPT produced a Mars rover’s titanium camera mount, surviving -120°C to +80°C cycles.

2. Medical: Engineering Life-Saving Tools

-

Spinal Implants: Ti-6Al-4V ELI with porous surfaces for bone fusion (Ra 0.4 µm).

-

Surgical Drills: Micro-machined 440C steel tips with 0.01 mm precision.

3. Automotive: Speed Meets Precision

-

EV Battery Housings: Aluminum A380 enclosures waterproof to IP68 standards.

-

Transmission Gears: 8620 steel gears hardened to HRC 60, AGMA Q12 certified.

Behind the Scenes: How JLYPT Maximizes CNC Capabilities

1. Multi-Axis Machining

-

5-Axis Systems: Create impellers with curved airfoils in one setup.

-

Swiss-Type Lathes: Machine Ø0.15 mm Nitinol wires for cardiac stents.

2. Material Mastery

-

Superalloys: Hastelloy X for corrosive environments.

-

Composites: Carbon fiber-reinforced polymers (CFRP) for lightweight drones.

3. Smart Technology Integration

-

IoT Sensors: Monitor tool wear in real time, reducing scrap by 18%.

-

AI Optimization: Adaptive toolpaths slash machining time by 25%.

Case Study: Custom Orthopedic Implant

Challenge: A medical firm needed 500 cobalt-chromium knee implants with Ra < 0.6 µm surfaces in 15 days.

JLYPT’s Solution:

-

Machine: 5-axis CNC mill with diamond-coated tools.

-

Process: High-speed finishing passes + ultrasonic cleaning.

-

Result: Delivered in 10 days, achieving 100% FDA compliance.

Sustainability in CNC Operations

-

Recycled Materials: 90% of titanium chips reused in new billets.

-

Energy Efficiency: Solar-powered CNC mills cut CO₂ by 30%.

-

Eco-Coolants: Non-toxic fluids (ISO 14001 compliant).

Why Partner with JLYPT?

-

Certifications: AS9100 (aerospace), ISO 13485 (medical), IATF 16949 (automotive).

-

Global Network: Factories in the EU, NA, and Asia ensure rapid delivery.

-

Cost Savings: DFM consultations reduce part costs by 20-35%.

Future Innovations: What Will CNC Machines Do Next?

-

Hybrid Manufacturing: Combine 3D printing and CNC finishing.

-

Nano-Machining: Sub-micron tolerances for semiconductor parts.

-

AI-Powered Self-Correction: Machines adjust toolpaths in real time.

Conclusion: The CNC Machine’s Role in Shaping Tomorrow

What does a CNC machine do? It transforms raw materials into the building blocks of innovation. From life-saving implants to interplanetary rovers, JLYPT’s CNC expertise ensures industries can meet tomorrow’s challenges today. By blending cutting-edge technology with sustainable practices, we redefine precision manufacturing for a smarter, faster world.

Ready to harness CNC power? Contact JLYPT for a consultation.