High-Precision CNC Machining for Robotics & Automation

Get high-quality manufacturing services for your custom robotic prototypes and production parts. Launch products faster, reduce risks, and streamline production processes with on-demand production at competitive prices.

- Production-grade products

- ISO 9001:2015 certified

- 24/7 engineering support

Why manufacture robotics & automation parts with JLYPT?

At JLY Precision Tech, we empower engineers and innovators in the robotics industry by transforming their concepts into reality. Our comprehensive manufacturing approach ensures:

Faster Time-to-Market: Leverage our rapid prototyping to iterate on designs and accelerate your development cycle.

Seamless Integration: Manufacture complex, high-tolerance parts that are built to work perfectly within your system.

Uncompromising Performance: Utilise advanced techniques to create durable, reliable components for demanding robotic & automation applications.

JLY Precision Tech is an ISO9001-2015 certified manufacturer that can guarantee reliable parts and prototypes suitable for industrial robotics and automation.

We can fulfill orders of virtually any size, from one-off prototypes to full production.

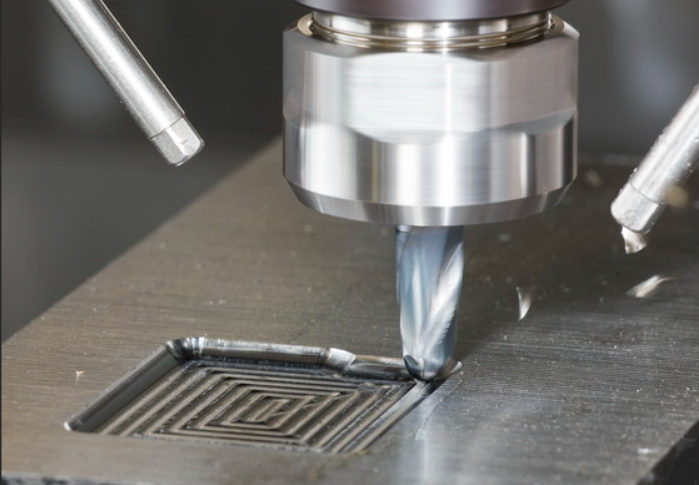

We guarantee precision for robotics through advanced Milling, Grinding, Turning, and 3D Printing—delivering parts that perform. Such as gears, motors and shaft.

Our precision machining allows for tolerances down to +/- 0.005 mm, suitable for micro and nano robotics systems.

Our extensive facilities and partner network allow us to fulfill orders quickly, no matter the quantity or complexity.

Our engineers specialize in optimizing your designs for peak performance in robotics and automation.

Our engineers will review your designs immediately to provide a fast and accurate quotation for the project.

Precision Manufacturing for the Robotics Industry

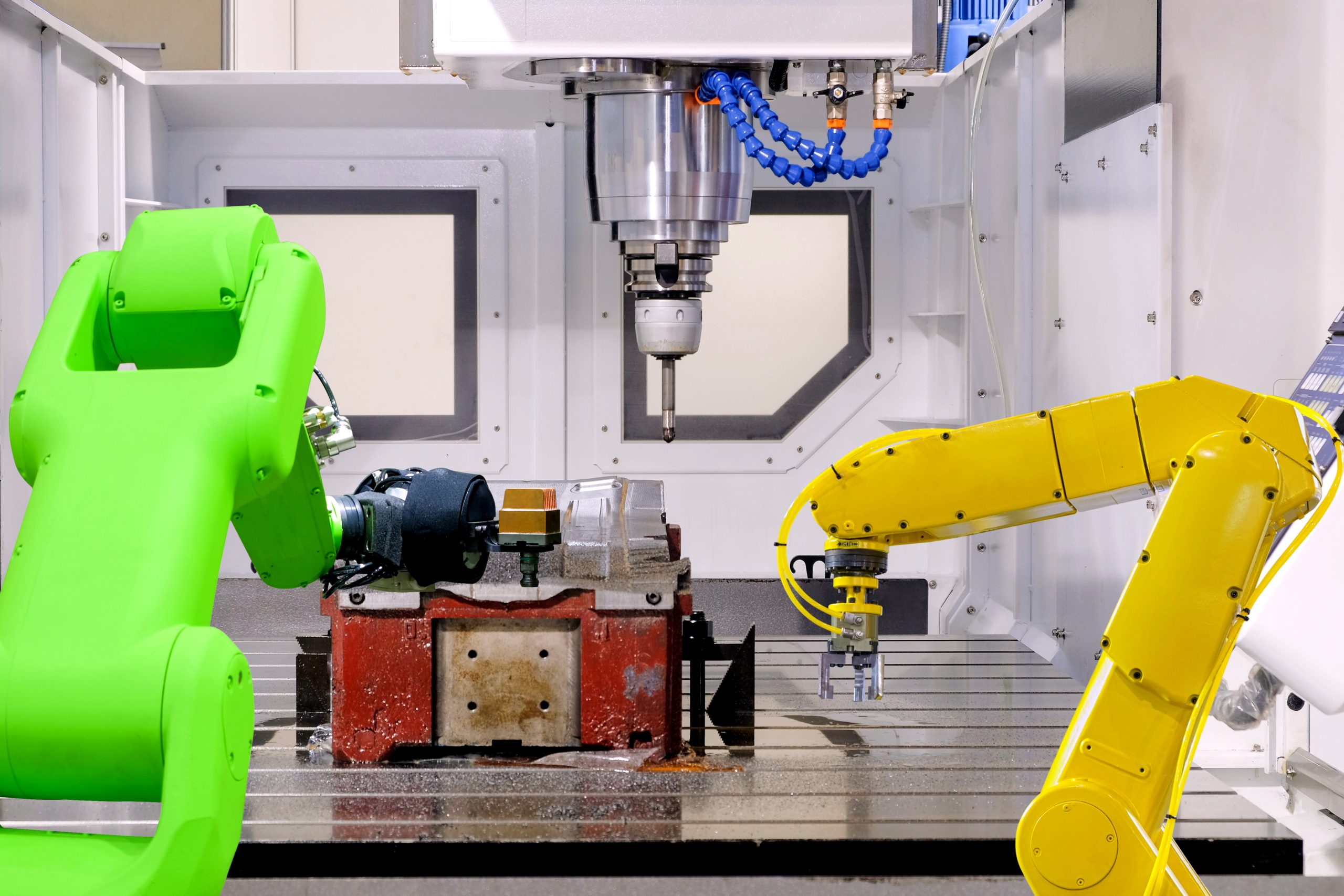

As innovation accelerates in the robotics industry, demand for specialized Robotic CNC machining services reaches new heights. At JLYPT, we combine decades of experience in robotics prototyping with cutting-edge digital manufacturing technologies to deliver mission-critical components for automation systems worldwide.

Robotic Prototyping

Robot prototyping is the rapid development and testing of robotic models to refine design, functionality, and performance before full-scale production.

Accelerating for the development of Robotic industry.

CNC machining accelerates robotics development by offering precise, efficient, and flexible manufacturing capabilities. It enables roboticists to create complex, customized components, rapidly iterate designs, and produce reliable, high-quality parts for a wide range of robotic applications.

- Tolerances as tight as +/-0.0002 in.

- IS09001 /IS013485 /ITAR /CMM Certification.

- 100% Pre-shipment inspection.

- Highly trusted by 100+ leading companies for our reliable services.

- Pioneering manufacturing and processing capabilities that redefine industry standards.

Below are some of the types of robotics parts we can manufacture for you:

- Robotic arms

- Robotic arms

- End effector

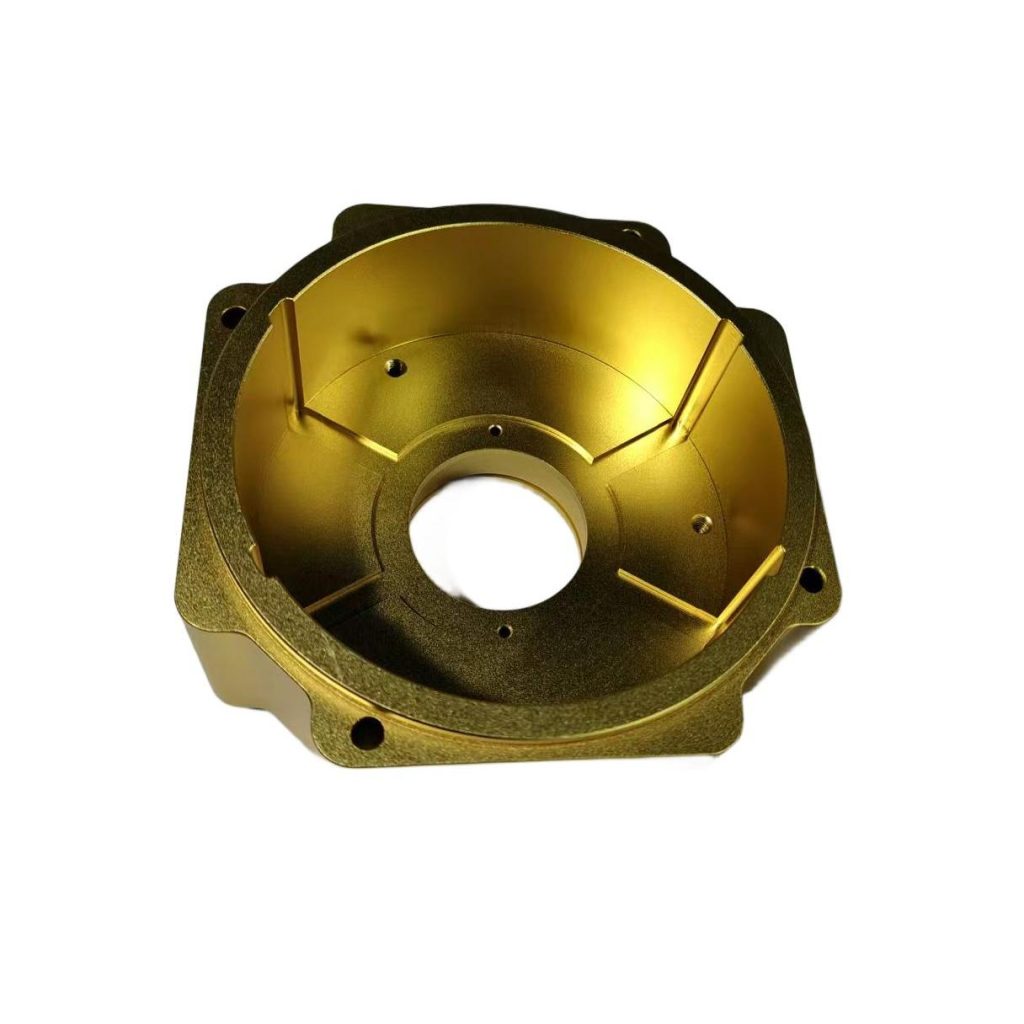

- Motor housings

- Motor housings

- Joint components

- Sensor brackets

- Sensor brackets

- Base plates

- Shaft

- Manipulator linkages

- Drive system components

- Drive system components

- Drive system components

- Cooling system components

Difference between robotics and automation

While often used together, robotics and automation are distinct:

Automation is the broader science of creating self-operating systems using computers, software, and machinery. It focuses on streamlining processes.

Robotics is a specific branch of automation that designs and builds physical machines (robots) to perform physical tasks.

In practice, they are powerful partners. An automated production line, for instance, often relies on multiple robots. However, automation can exist without robotics (e.g., software scripts), and robotics can exist without full automation (e.g., a surgeon-assisted medical bot).

Our Role in Your Ecosystem

As specialists in prototyping and manufacturing physical components, JLYPT is a key partner for both fields.

For Robotics: We produce high-precision parts for arms, grippers, and actuators.

For Broader Automation: We also manufacture critical components for conveyor systems, control equipment, and logic controllers.

We provide the physical foundation that advanced systems are built upon.

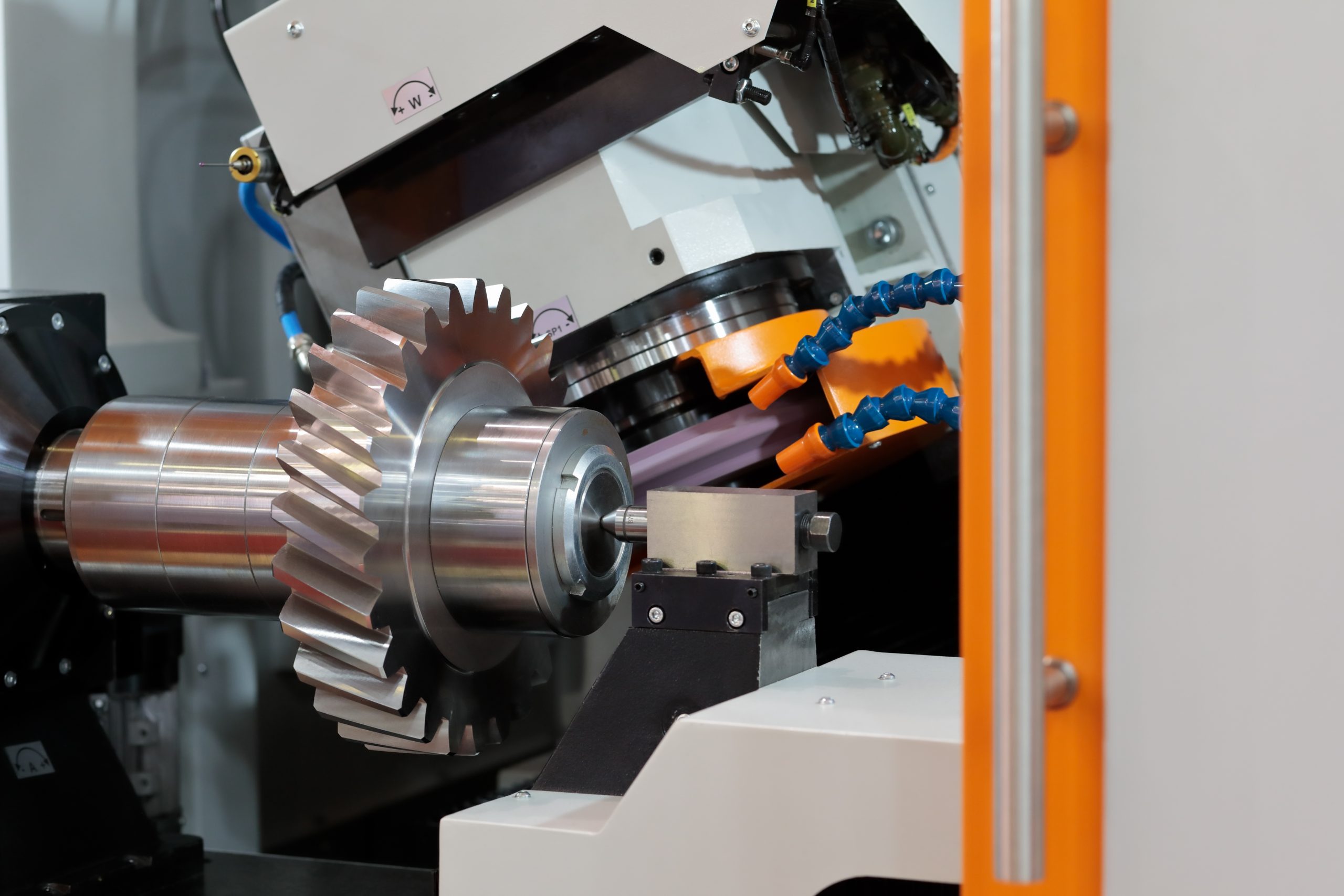

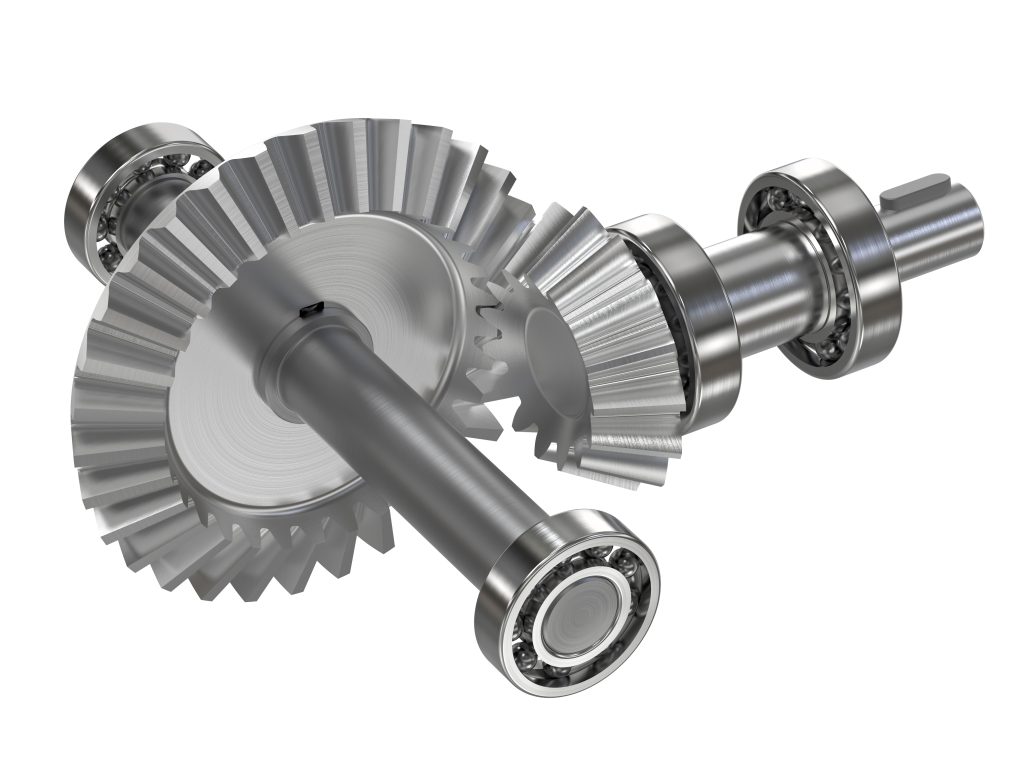

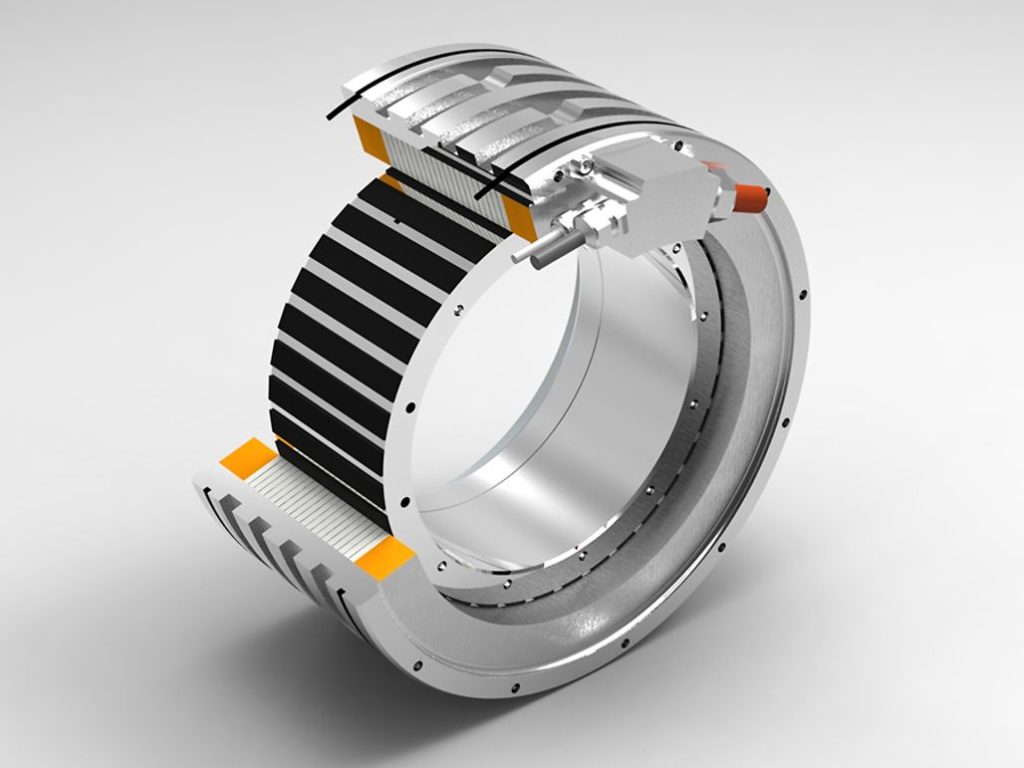

Robotic Gears & Motors

Here are some specific examples of CNC machining applications in the robotics industry. CNC machining is essential for manufacturing key components of robotic gears & motors. These parts demand high precision to ensure accurate movement and positioning, making CNC machining a critical process for robotic performance.

Robotics & automation manufacturing processes

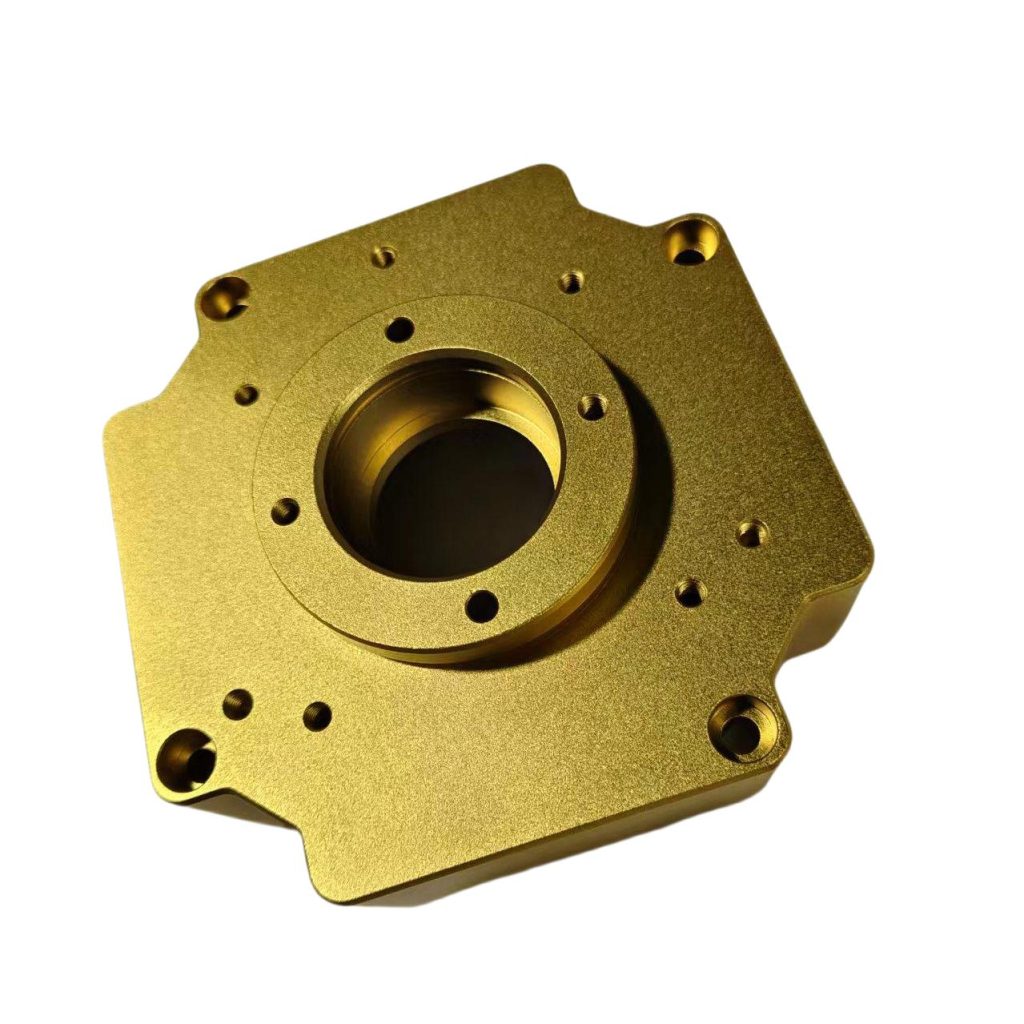

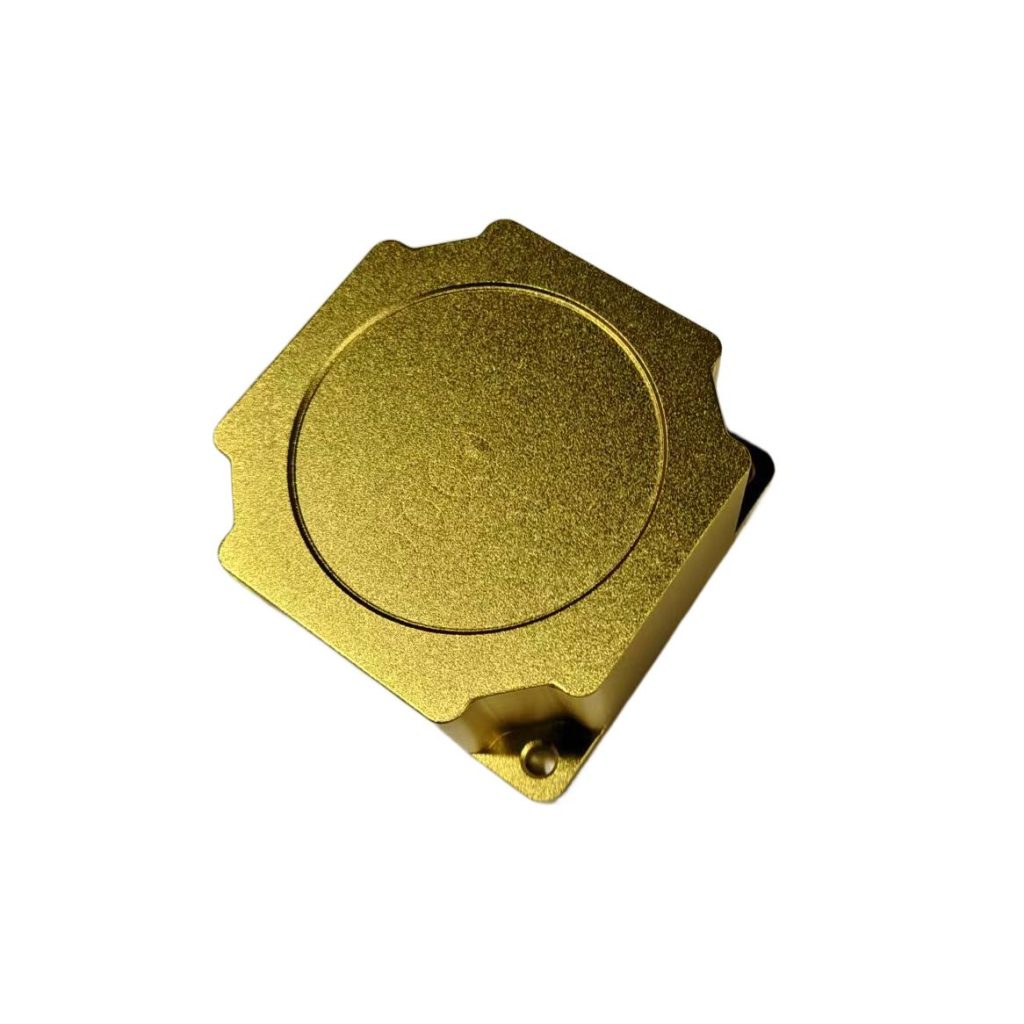

Robotics & Automation Part Gallery

For the years we have gathered relevant experience that enables us to handle any robotic projects. Here’s the gallery of robotic prototypes and production parts for our worldwide clients.

Selection Of Material Available For Robotic Industry

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for robotic projects are listed below.

| Best technologies | Benefits | Example parts | |

| Stainless Steel | CNC machining, sheet metal | Strong, corrosion-resistant, sterilizable, range of grades | Surgical instruments, Heat exchangers, pumps, tubing |

| Aluminum | CNC machining, rapid tooling, sheet metal | Machinable, strong, range of grades | Cylinder heads, manifolds, Ductwork, housings, bus ducts |

| POM/Delrin | CNC machining, injection molding | Strong, lightweight, low friction | Casings, housings |

| Casings, housings | Liquid silicone injection molding | Durable, flexible, biocompatible, inert | Seals, cover assemblies, Fluid management devices, respiratory devices |

| Urethanes | Vacuum casting | Transparent, affordable | Casings, housings |

Surface Finished Available For Robotic Industry

High-Precision Surface Finishes for Optimal Robotic Performance

| Name | Applicable to | Feature | Color | Thickness |

| As machined | Metals & Plastics | Tool marks visible | N/A | N/A |

| Sanding & Polishing | Metals & Plastics | Brushed & gloss mirror surface | N/A | 0.02-0.05mm removed |

| Sand, Bead Blasted | Metals & Plastics | matt or satin surface | N/A | N/A |

| Painted | Metals & Plastics | Metals & Plastics | colors can be matched as needed | 0.05mm to 0.1mm |

| Powder coat | Metals | Matt, Gloss & Texture | colors can be matched as needed | 0.05mm to 0.15mm |

| Anodized | Aluminum | Tool marks visible, Smooth, Matt & Gloss | colors can be matched as needed | 0.002mm to 0.04mm |

| E-Coating | Metals | Matt & Gloss | Black | 0.015mm to 0.035mm |

| Nickel Plating | Metals | Gloss | Silver | 0.004mm to 0.05mm |

| Chromed | Metals & Plastics | Satin & Gloss | Silver | 0.001mm to 0.3mm |

| Zinc Plating | Metals | Gloss | Silver | 0.005mm to 0.2mm |

| Chromate Conversion Coating | Aluminum | Tool marks visible, Smooth and Matt | Clear/ slight yellow tint | 0.25-1 um |

FAQs

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.