JLYPT delivers micro-scale CNC parts with ±0.005 mm capability. We machine thin walls, micro bores/ports, intersecting channels, and fine threads using 3-/4-/5-axis milling, Swiss-type turning, EDM/wire EDM, and surface grinding. Parts ship burr-free to the specified Ra with controlled runout and full inspection records (CMM reports, FAI/PPAP on request) and EN 10204 3.1 material traceability. Materials include 17-4/316L stainless, titanium, copper/aluminum alloys, and engineering plastics such as PEEK.

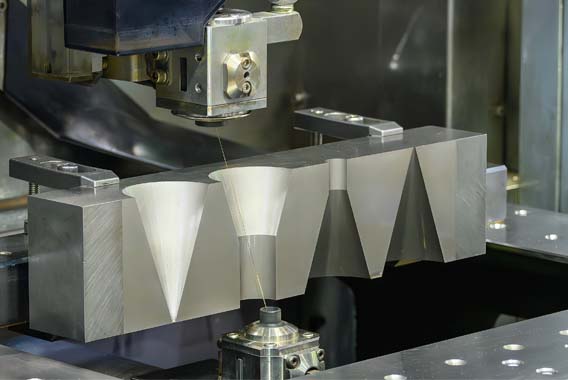

What is Micromachining?

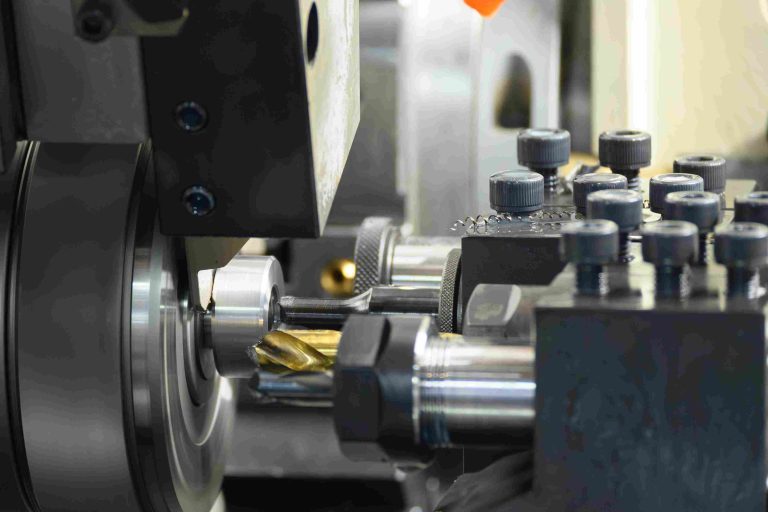

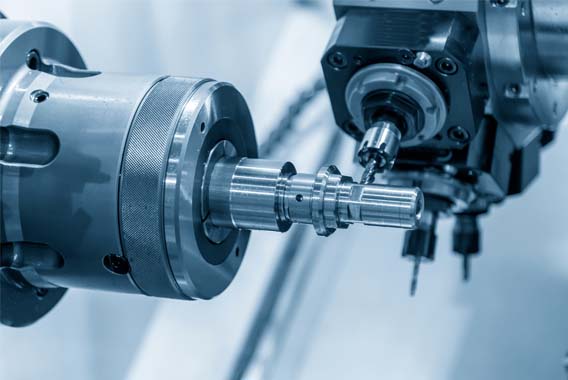

Micromachining produces sub-millimeter components by combining ultra-precise tooling, rigid fixturing, and purpose-built CNC/EDM platforms. With micron-level tolerances and burr-free finishes, it enables intricate features for medical and electronics applications. Because many details are smaller than the eye can see, parts are verified with high-resolution inspection, such as CMM, optical vision, and microscopy.

Micro Precision Parts Machining

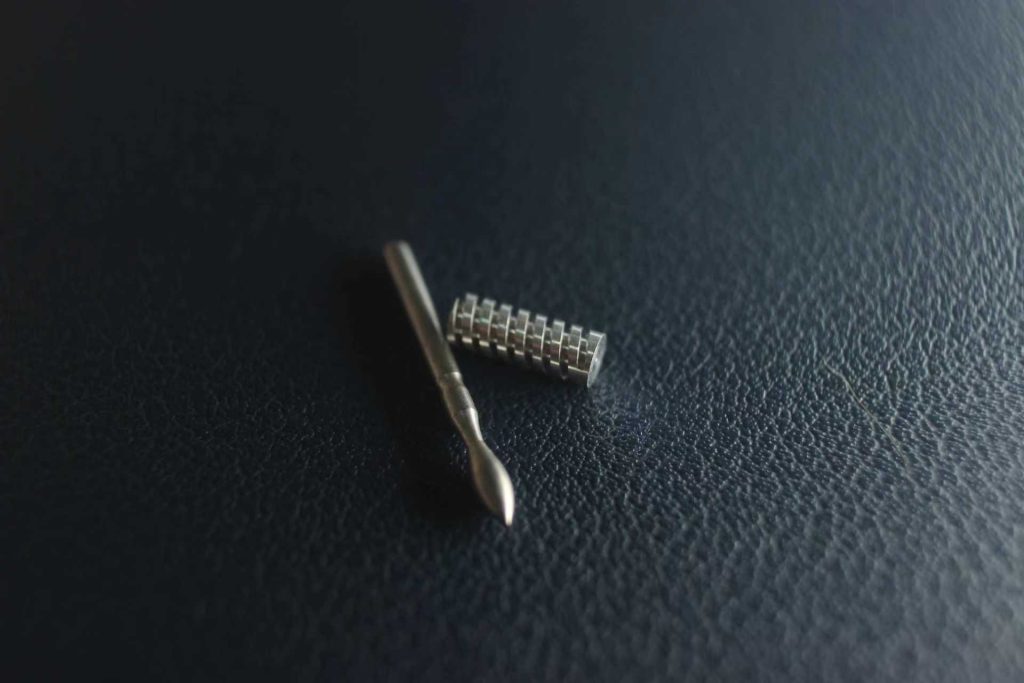

Micro Gears

Micro gears are precision components with sub-millimeter modules engineered for compact, low-noise transmissions. We machine spur and helical forms via micro-hobbing, shaping, and wire-EDM, then stabilize profile and finish with fine grinding/lapping. Pitch, runout, and tooth form are held to micron-level tolerances; burr-free edges and controlled root fillets protect mating parts. Materials include 17-4/316L stainless, titanium, brass/copper and aluminum alloys, and engineering plastics (e.g., PEEK). Each lot is verified by optical gear metrology/CMM with involute/lead charts and roughness checks to your Ra target. Typical uses: medical drives, micro-actuators, sensors, and miniature robotics.

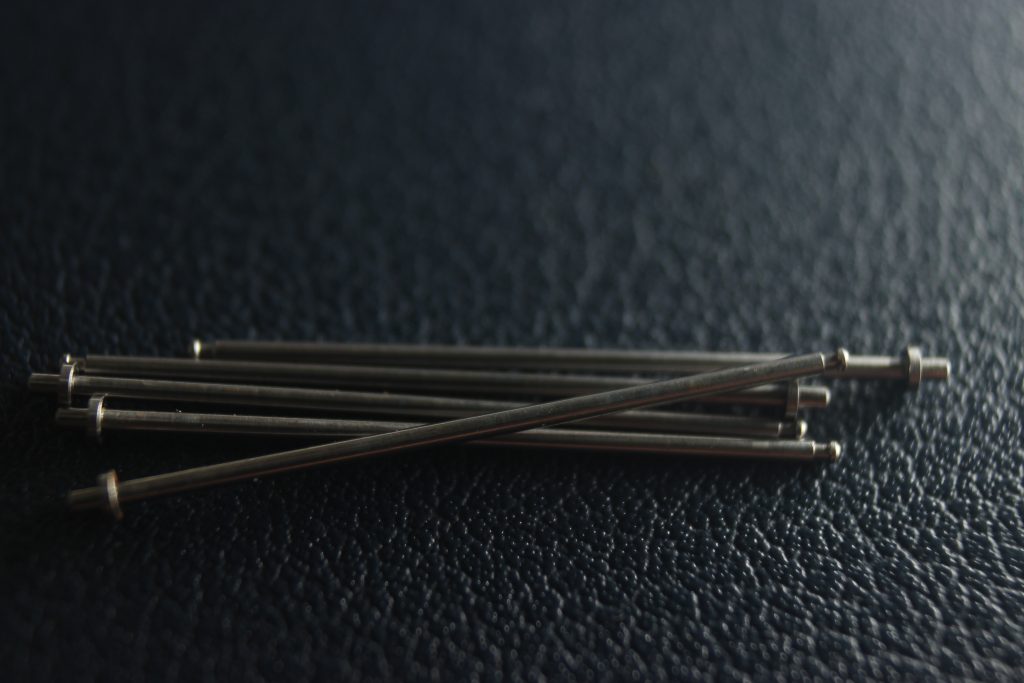

Micro Shafts

Micro shafts are precision-turned components with sub-millimeter features where straightness, concentricity, and surface finish determine performance. JLYPT manufactures stepped and uniform shafts with controlled OD/ID tolerances (micron-level), low runout, and burr-free edges. Typical features include shoulders, grooves, flats, micro keyways, cross-holes, and fine-pitch threads. Processes span Swiss-type turning (guide-bushing), cylindrical/centerless grinding, lapping/honing for finish, and wire-EDM for slots or intersecting features. Parts are verified via optical metrology/CMM with roundness, cylindricity, and length checks to print. Materials include 17-4/316L stainless, titanium, tool steels, brass/copper and aluminum alloys, and engineering plastics such as PEEK. Applications: medical pumps and instruments, micro-actuators/motors, sensors, and miniature robotics.

Micro Fitting

Micro fittings require leak-tight geometry, clean edges, and consistent surface finishes. JLYPT machines miniature ports and threads—Luer tapers, UNF/metric fine threads, ferrule seats, and O-ring glands—to micron-level tolerances with burr-free edges that protect seals. Processes include Swiss-type turning, micro-milling, EDM for intersecting passages, and honing/lapping of sealing faces to the specified Ra. We control concentricity and chamfer/radius calls so assemblies mate smoothly and hold pressure. Materials span 316L/17-4 stainless, titanium, Hastelloy, brass/copper and aluminum alloys, and engineered polymers (e.g., PEEK, PTFE). Verification uses CMM/optical metrology, thread gauges, air/pin gauging for bores, surface roughness checks, and (when specified) pressure/helium leak tests. Documentation: CMM report, FAI/PPAP on request, and EN 10204 3.1 material traceability.

Why Choose JLYPT for Micromachining

Here are five points highlighting JLYPT’s capabilities in precision manufacturing:

Micron-level accuracy

Hold ±0.005 mm and finishes to Ra ≤ 0.2 µm

Micro-feature expertise

We thrive on tackling intricate geometric challenges, delivering precise internal and external features tailored to your specific needs.

End-to-end processes

3–7-axis , Swiss-type lathe, grinding, and EDM for stable, repeatable results.

Materials mastered

316L/17-4, titanium, aluminum, copper alloys, Inconel/Hastelloy.

Verified quality

CMM dimensional reports, FAI on request, EN 10204 3.1 traceability.

Precision Micromachining Solutions by JLYPT: Engineering the Impossible

See How We Deliver Unmatched Precision, Complexity, and Reliability: