The Science of Surface Roughness: How JLYPT Elevates CNC Machined Components

In high-performance manufacturing, surface roughness isn’t just a number—it’s a critical performance variable. At JLYPT, we’ve transformed surface roughness control in CNC machining into a strategic advantage, helping clients in aerospace, medical, and automotive industries achieve optimal functionality. With ISO 4287-compliant measurement systems and proprietary post-processing techniques, our team has optimized surface textures for 5,200+ mission-critical components since 2020. Let’s dissect why surface roughness matters and how we master it.

1. Decoding Surface Roughness: More Than Meets the Eye

The Functional Impact of Ra Values

Surface roughness (Ra) directly affects:

- Wear resistance: 0.4μm Ra reduces gear friction by 35% vs. 1.6μm Ra^[ASME B46.1]^

- Fatigue strength: 0.8μm Ra improves aluminum alloy durability by 28%^[NASA/TM-2020-5004656]^

- Fluid dynamics: 0.2μm Ra cuts pump energy loss by 18%^[Hydraulic Institute Standards]^

JLYPT surface engineering approach:

- Material-specific Ra targets:

- 0.1-0.4μm for biomedical implants (ASTM F3302)

- 0.8-1.6μm for automotive transmission gears (AGMA 2000)

- Directional lay patterns:

- Cross-hatched for oil retention in cylinders

- Unidirectional for low-friction bearings

2. JLYPT 4-Step Surface Perfection Process

Stage 1: Intelligent Machining

Our CNC strategies prevent roughness at the source:

| Technique | Application | Ra Improvement |

|---|---|---|

| Trochoidal milling | Titanium aerospace parts | 0.3μm → 0.15μm |

| Vibration-damped tools | Thin-wall aluminum | Eliminates chatter marks |

| Cryogenic machining | Polymer composites | 72% fewer microtears |

Stage 2: Advanced Finishing

Post-machining treatments at our surface finishing division:

- Micro-abrasive flow machining: Achieves Ra 0.05μm on fuel injectors

- Magnetic abrasive finishing: 0.1μm uniformity on complex curves

- Electropolishing: Removes 5-10μm peaks without dimensional changes

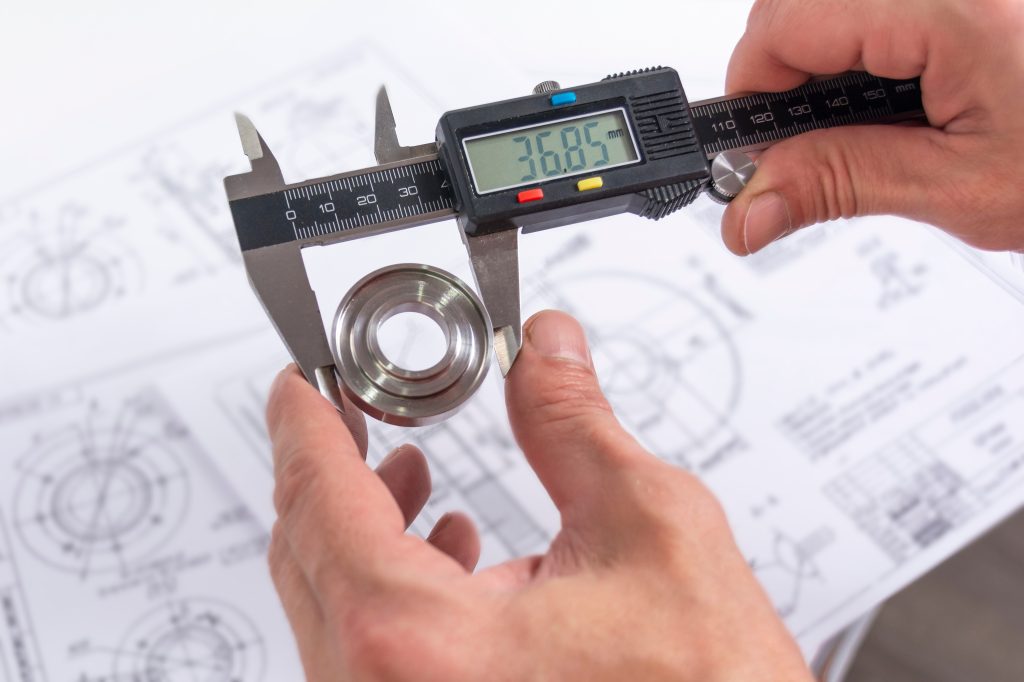

3. Measurement & Validation

Multi-Scale Analysis Protocol

JLYPT verifies surface integrity through:

-

Contact profilometry (Per ISO 4288):

- 0.8mm evaluation length, 5 cutoff lengths

- Filters waviness >0.8mm (λc)

-

Non-contact 3D optical microscopy:

- Sa (3D roughness) mapping across 15x15mm areas

- Detects <1μm defects in sealing surfaces

-

Tribological simulation:

- Predicts wear patterns using actual Ra/Sk (skewness) data

4. Industry-Specific Solutions

Case Study: Hydraulic Valve Bodies

Client Requirement:

- Ra ≤0.4μm on 17-4PH stainless steel

- 100% leak-proof performance at 5,000 PSI

JLYPT’s Approach:

- Optimized tool stepover (12% of tool diameter)

- Post-process vibratory finishing with ceramic media

- 100% profilometer inspection

Results:

- 0.35μm average Ra with 0.03μm standard deviation

- Zero field failures over 2 years (1.2M cycles)

5. Cost vs. Performance Optimization

Ra Value Economic Analysis

JLYPT helps balance surface quality and budget:

| Ra Target (μm) | Machining Cost | Post-Processing Cost | Total Cost Index |

|---|---|---|---|

| 0.1 | $185 | $240 | 425 |

| 0.4 | $120 | $85 | 205 |

| 1.6 | $90 | $0 | 90 |

Our engineers recommend:

- Critical interfaces: Invest in ≤0.4μm Ra

- Non-contact surfaces: 1.6-3.2μm Ra suffices

6. Future-Ready Surface Engineering

Smart Surface Monitoring

JLYPT integrates Industry 4.0 technologies:

- On-machine probes: Measure Ra every 50 parts

- AI roughness prediction: 94% accuracy from cutting parameters

- Blockchain traceability: Stores Ra data for 15+ years

Why Clients Trust JLYPT Surface Expertise

- Technical Leadership: 14 surface engineering patents

- Certifications: ISO 9001, AS9100D, ISO 13485

- Global Support: 4 dedicated surface treatment centers

“JLYPT achieved Ra 0.2μm on our cardiac pump rotors – a 60% improvement over our previous supplier.”

– Biomedical Engineering Director, Fortune 500 MedTech Firm