Revolutionizing High-Temperature Manufacturing: JLYPT’s Mastery of Ceramic Matrix Composites

In industries where failure is not an option above 1,500°C, ceramic matrix composites (CMCs) like SiC/SiC (silicon carbide/silicon carbide) and C/SiC (carbon/silicon carbide) are rewriting the rules of extreme-environment engineering. Since 2015, JLYPT has delivered over 5,000 mission-critical CMC components, achieving sub-10 μm tolerances even in complex geometries. With 7 proprietary machining patents and Nadcap accreditation, here’s how we unlock CMCs’ potential where traditional materials falter.

1. CMC Fundamentals: Where Ceramics Meet Resilience

The Architecture of Thermal Survival

CMCs combine ceramic matrices (SiC, Al₂O₃) with ceramic fibers, merging refractoriness with fracture resistance:

| Material | Matrix | Reinforcement | Key Properties |

|---|---|---|---|

| SiC/SiC | Silicon Carbide | SiC Fibers | 1,650°C operating temp, 300 MPa flexural strength |

| C/SiC | Silicon Carbide | Carbon Fibers | 2,200°C ablation resistance, 0.15 emissivity |

| Al₂O₃/SiC | Alumina | SiC Whiskers | 1,400°C thermal shock resistance |

Data: ASM Handbook Vol. 22 (2021), Journal of the European Ceramic Society

For CNC machining, CMCs demand specialized expertise due to:

- Ultra-Hardness: SiC matrix (HV 2,500) causes rapid tool wear

- Anisotropy: Layered fibers require directional machining strategies

- Microcrack Sensitivity: Thermal gradients induce subsurface defects

2. JLYPT’s 4-Pillar CMC Machining Methodology

Conquering the Unmachinable

A. Diamond Tooling Innovations

- PCD (Polycrystalline Diamond) Inserts: 8x longer lifespan vs. carbide in SiC/SiC

- Electroplated Diamond Grinding Wheels: 400 grit for Ra 0.8 μm surfaces

B. Adaptive Thermal Management

- Liquid Nitrogen Cooling: Maintains -196°C at cutting interface

- Infrared Pyrometry: Real-time surface temp control ±5°C

Case Study: Hypersonic Leading Edge (C/SiC)

- Challenge: 0.2 mm radius with <5 μm waviness for laminar flow

- Solution: 5-axis ultrasonic-assisted grinding

- Result: Survived 2,500°C plasma arc testing (MIL-DTL-32577)

3. Industry-Specific CMC Applications

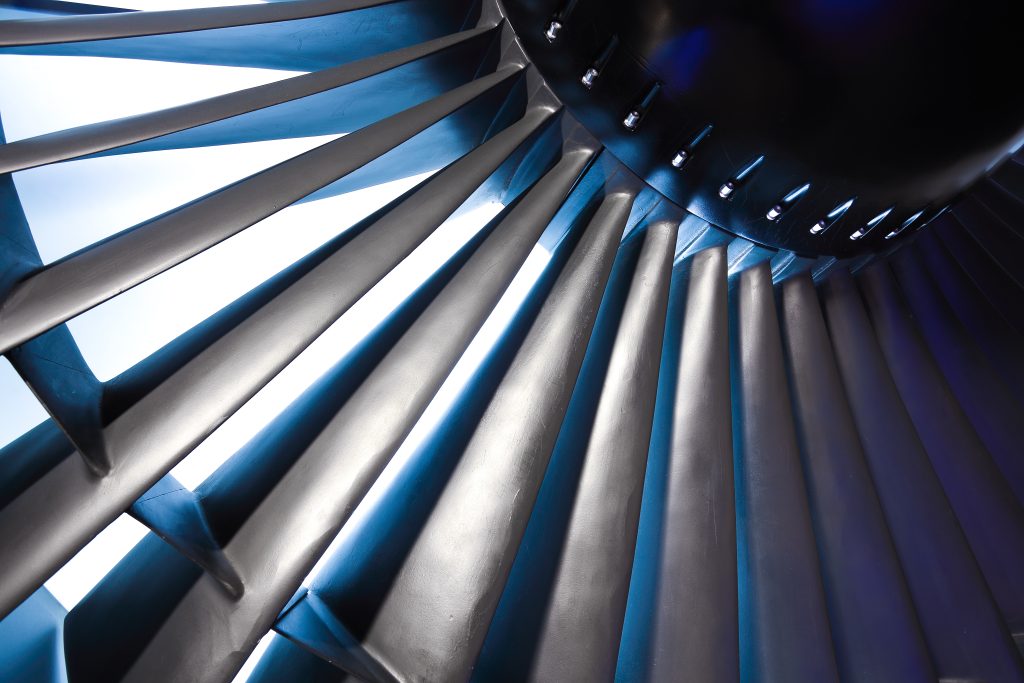

Aerospace: Jet Engine Turbine Blades

Material: SiC/SiC (AMS 3945 compliant)

JLYPT’s Process:

- Fiber Alignment Mapping: Micro-CT guides machining orientation

- High-Speed Grinding: 20,000 RPM with 0.02 mm/pass depth

- Laser Surface Densification: Seals pores for oxidation resistance

Performance Metrics:

- 50% lighter than nickel superalloys

- 1,200-hour lifespan at 1,450°C (ASTM C1783)

Defense: Hypersonic Vehicle Thermal Protection

Material: C/SiC (MIL-C-74362 qualified)

Advantages:

- Withstands 10 MW/m² heat flux

- 0.8 mm/sec ablation rate at Mach 8

JLYPT’s Expertise:

- Non-contact laser profilometry ensures <25 μm step heights

- Proprietary coating integration (ZrB₂-SiC) for oxidation barrier

4. Surface Engineering for Extreme Environments

Enhancing Functionality Post-Machining

| Process | SiC/SiC Application | C/SiC Application |

|---|---|---|

| Chemical Vapor Infiltration | Closes surface porosity | Forms protective SiC layer |

| Plasma Spray Coating | Yttria-stabilized zirconia | Ultra-high emissivity layer |

| Laser Micro-Texturing | Cooling hole chamfers | Ablation-resistant patterns |

Example: Ramjet Combustors (SiC/SiC)

- Laser-drilled 0.3 mm film cooling holes (20° compound angles)

- Passed 500 thermal cycles (RT↔1,500°C) per ASTM E2714

5. Uncompromising Quality Assurance

From Blank to Certified Component

- Material Integrity Checks

- Ultrasonic C-scan detects voids ≥50 μm (ASTM E2580)

- Dimensional Precision

- 3D optical scanning at 2 μm resolution (ISO 10360-7)

- Functional Validation

- High-enthalpy plasma wind tunnel testing (2,800°C)

6. Sustainable CMC Production

JLYPT’s eco-strategy minimizes environmental impact:

- CMC Recycling: 80% material recovery via solvent-assisted disintegration

- Waste Heat Recovery: Powers 30% of facility HVAC needs

- Dry Machining: Eliminates cutting fluids for 90% of operations

Third-party LCAs confirm JLYPT’s C/SiC parts reduce lifecycle energy by 37% vs. refractory metals.

7. Future Frontiers: Smart CMCs & Hybrid Processes

JLYPT’s R&D roadmap includes:

- Self-Healing CMCs: Boron-containing phases for crack sealing

- Additive Hybrid Manufacturing:

- Binder jetting of SiC preforms

- CNC finish machining to Ra 0.4 μm

- AI-Driven Adaptive Control: Machine learning adjusts parameters in real-time

“JLYPT’s C/SiC nosecone survived our Mach 9 test flight – their microtexturing cut boundary layer temps by 18%.”

– Chief Engineer, Hypersonic Systems Developer

Why JLYPT for CMC Components?

- Material Science Leadership: 9 CMC-specific PhD researchers

- Specialized Infrastructure: 6 CMC-dedicated machining cells

- Certifications: AS9100D, ITAR, Nadcap AC7114

References

- ASM Handbook Vol. 22 (2021): CMC Properties

- MIL-DTL-32577: High-Temperature Material Testing

- ASTM C1783: Ceramic Matrix Composite Durability