Vacuum Plating for Optical Instrument Components in CNC Machining

Introduction

Optical instruments, renowned for their precision and accuracy, demand components with exceptional optical properties and aesthetic appeal. Vacuum plating, a sophisticated surface finishing technique, plays a pivotal role in enhancing these attributes. As a leading CNC machining service provider in China, Jlypt specializes in integrating vacuum plating for optical instrument components within the CNC machining process. This article delves into the nuances of vacuum plating for optical instrument components, showcasing its benefits, processes, applications, and real-world case studies.

Benefits of Vacuum Plating for Optical Instrument Components

1. Enhanced Optical Properties

Vacuum plating imparts a thin, uniform layer of metal or other materials onto optical components, improving their reflective, transmissive, or absorptive properties.

2. Superior Aesthetic Appeal

The resultant coating can offer a high-gloss finish, adding a touch of elegance and sophistication to optical instruments.

3. Corrosion and Wear Resistance

Vacuum plated coatings provide robust protection against corrosion and wear, ensuring the longevity of optical components.

4. Customizable Colors and Finishes

The technique allows for a wide range of colors and finishes, catering to specific design requirements and enhancing the overall visual impact of optical instruments.

Jlypt’s Vacuum Plating Services for Optical Instrument Components

Services Offered

- Precision Vacuum Plating: Utilizing advanced vacuum chambers and deposition techniques to ensure uniform coating thickness and high optical quality.

- Custom Coatings: Developing tailored coating formulations to meet specific optical and aesthetic requirements.

- Batch Processing: Efficiently processing multiple optical components simultaneously to reduce lead times and costs.

- Quality Assurance: Rigorous testing and inspection protocols to ensure coating integrity, optical performance, and compliance with industry standards.

Detailed Table of Services

| Service Type | Application | Characteristics | Example Image |

|---|---|---|---|

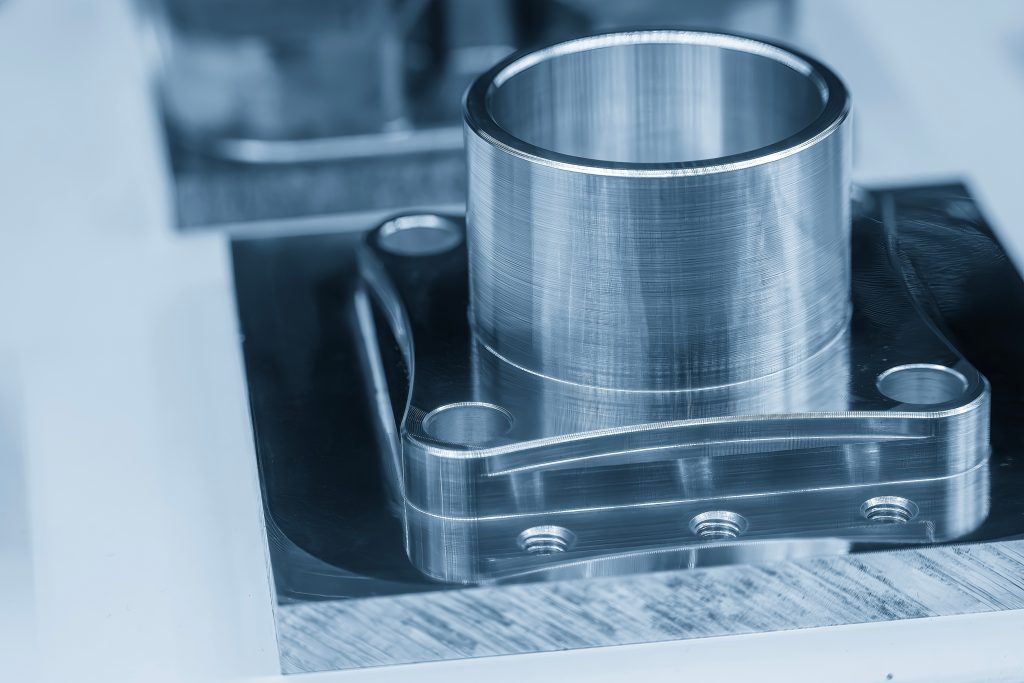

| Precision Vacuum Plating | Mirrors, lenses, prisms, filters | Uniform coating thickness; high optical quality; customizable colors and finishes |  |

| Custom Coatings | Specialized optical components, decorative elements | Tailored to specific optical and aesthetic requirements; enhanced durability and performance |  |

| Batch Processing | High-volume production of optical components | Cost-effective; time-efficient; consistent coating quality across all components |  |

| Quality Assurance | All vacuum plated optical components | Rigorous testing; compliance with industry standards and customer specifications |  |

Case Studies

Case Study 1: Mirrors for High-Precision Telescopes

A renowned telescope manufacturer approached Jlypt for precision vacuum plating services for their telescope mirrors. The mirrors required a high-reflectivity coating to maximize light transmission and enhance imaging quality. Jlypt’s advanced vacuum plating techniques ensured a uniform and defect-free coating, significantly improving the optical performance of the mirrors.

Case Study 2: Lenses for Medical Imaging Devices

A medical device company sought Jlypt’s expertise for custom vacuum plating of their imaging device lenses. These lenses needed a specific transmittance and color correction to ensure accurate and high-quality images. Jlypt developed a tailored coating formulation that met these stringent requirements, resulting in lenses with exceptional optical clarity and color accuracy.

Case Study 3: Decorative Elements for Luxury Optical Instruments

A high-end optical instrument brand partnered with Jlypt for batch processing of vacuum plated decorative elements. These elements, including bezels, knobs, and covers, required a luxurious, high-gloss finish to complement the instrument’s overall design. Jlypt’s batch processing capabilities allowed for efficient and cost-effective coating application, ensuring consistent coating quality and enhancing the aesthetic appeal of the optical instruments.

Conclusion

Vacuum plating is a crucial surface finishing technique for optical instrument components, enhancing their optical properties, aesthetic appeal, and durability. At Jlypt, we offer a wide range of vacuum plating services specifically designed for optical instrument components within the CNC machining domain. Our expertise, combined with state-of-the-art equipment and skilled technicians, ensures that every optical component leaves our facility with a coating that meets or exceeds industry standards.

For more information or to request a quote, please visit our website at https://www.jlypt.com/anodizing-near-me-surface-finishing-services/ or contact us at [email protected]. We look forward to partnering with you on your next optical instrument component coating project!