Precision SLA 3D Printing Services

A 2025 Guide for Engineers, Dentists & Designers

Introduction

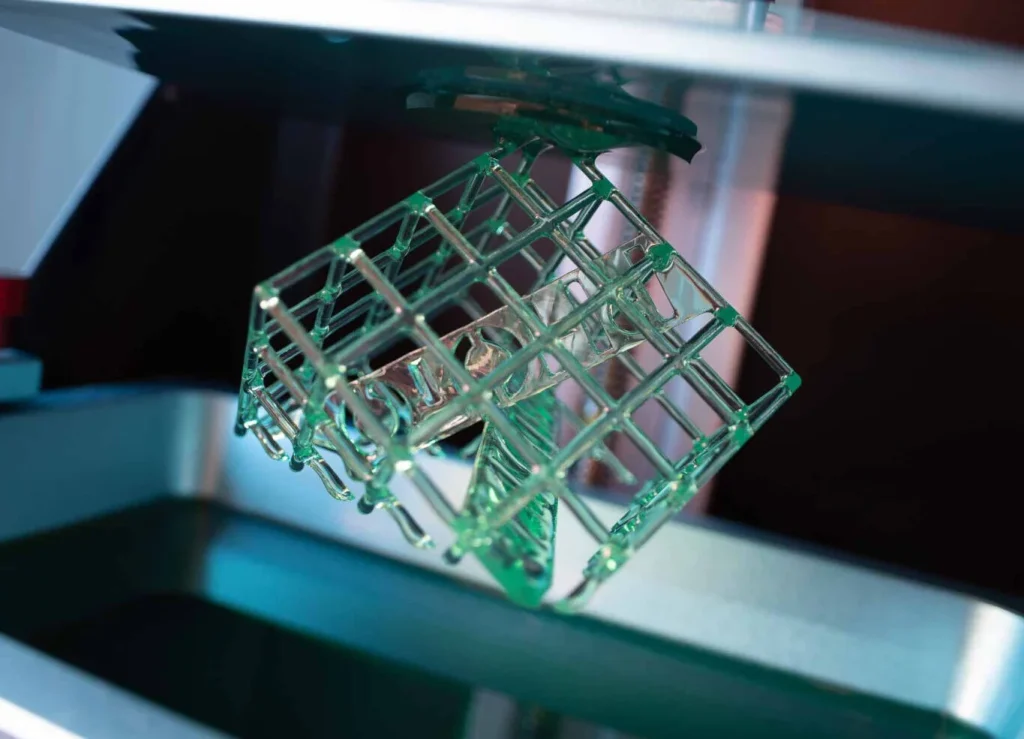

Stereolithography (SLA) remains the gold standard when surface finish, fine features, and tight tolerances matter. By curing liquid photopolymer with a UV laser, SLA delivers injection-mold quality without molds—ideal for prototypes, master patterns, and low-volume end-use parts. JLYPT operates 60 industrial SLA systems, including eight Formlabs Form 3L and two Nexa3D NXE 400Pro units, capable of 25 µm Z resolution and 350 × 350 × 400 mm builds. This guide distills resin science, design tactics, cost levers, and three fresh case studies that saved clients weeks and tens of thousands in tooling.

Stereolithography (SLA) remains the gold standard when surface finish, fine features, and tight tolerances matter. By curing liquid photopolymer with a UV laser, SLA delivers injection-mold quality without molds—ideal for prototypes, master patterns, and low-volume end-use parts. JLYPT operates 60 industrial SLA systems, including eight Formlabs Form 3L and two Nexa3D NXE 400Pro units, capable of 25 µm Z resolution and 350 × 350 × 400 mm builds. This guide distills resin science, design tactics, cost levers, and three fresh case studies that saved clients weeks and tens of thousands in tooling.

Table 1 — SLA Resin Portfolio (2025)

| Resin | Tensile (MPa) | Flex Mod (MPa) | HDT (°C) | Use Case | Color |

|---|---|---|---|---|---|

| GP-Clear 25 | 65 | 2,300 | 52 | Optics, lenses | Water-clear |

| Tough-X | 80 | 2,800 | 60 | Snap-fits | White |

| Dental Model | 75 | 2,600 | 65 | Ortho models | Beige |

| Castable Purple | 45 | 2,100 | 45 | Jewelry wax | Purple |

| Bio-Med Clear | 55 | 2,200 | 50 | Surgical guides | Translucent |

| High-Temp Gray | 95 | 3,400 | 120 | Under-hood | Gray |

| ESD-Safe | 50 | 2,300 | 55 | Electronics | Black |

Table 2 — Layer Height vs. Surface & Time

| Layer (µm) | XY (µm) | Surface Ra (µm) | Build Speed (mm/h) | Relative Cost | Best For |

|---|---|---|---|---|---|

| 25 | 75 | 0.8 | 12 | 3.0× | Micro-fluidics |

| 50 | 75 | 1.2 | 25 | 1.8× | Dental models |

| 100 | 75 | 2.0 | 45 | 1.0× | Prototypes |

| 200 | 75 | 3.5 | 80 | 0.7× | Draft housings |

Section 1 — Design Guidelines for SLA Success

1.1 Wall & Feature Size

• Minimum wall: 0.4 mm for GP resins, 0.6 mm for filled grades.

• Pins & text: 0.35 mm positive height, 0.5 mm width to prevent wash-away.

• Minimum wall: 0.4 mm for GP resins, 0.6 mm for filled grades.

• Pins & text: 0.35 mm positive height, 0.5 mm width to prevent wash-away.

1.2 Drain & Vent Holes

• Hollow parts ≥ 2 mm drain every 30 mm cavity length.

• Angled 45° to avoid resin pooling.

• Hollow parts ≥ 2 mm drain every 30 mm cavity length.

• Angled 45° to avoid resin pooling.

1.3 Support Strategy

• Light-touch supports (tip Ø 0.3 mm) leave <0.1 mm nibs.

• Use internal supports on cosmetic faces to keep exterior flawless.

• Light-touch supports (tip Ø 0.3 mm) leave <0.1 mm nibs.

• Use internal supports on cosmetic faces to keep exterior flawless.

1.4 Tolerance Budget

• Standard: ±0.1 mm or ±0.1 %, whichever larger.

• Post-cure shrinkage: compensate +0.05 % on critical fits.

• Standard: ±0.1 mm or ±0.1 %, whichever larger.

• Post-cure shrinkage: compensate +0.05 % on critical fits.

Section 2 — Post-Processing Roadmap

| Step | Equipment | Time | Notes |

|---|---|---|---|

| Ultrasonic wash | 99 % IPA bath | 5 min | Removes uncured resin |

| UV cure chamber | 405 nm, 60 °C | 15 min | Nitrogen purge for tack-free finish |

| Support removal | Micro-shears | 2–5 min | Leaves <0.1 mm nibs |

| Light polish | 3,000 grit | 5 min | Boosts clarity for clear resins |

| UV coating | Spray booth | 10 min | Scratch resistance for lenses |

Section 3 — Cost Drivers & Instant Estimator

| Factor | Impact | Tip to Save |

|---|---|---|

| Volume | Linear | Hollow + lattice |

| Height | Exponential | Orient flat |

| Layer | 2× cost @ 25 µm | Use 50 µm for drafts |

| Resin | GP vs. specialty | Validate fit with GP first |

| Finish | Polish adds 30 % | Limit to visible faces |

Instant Quote Table (50 µm layer)

| Volume Range | Standard Resin | Specialty Resin | Rush (24 h) |

|---|---|---|---|

| < 50 cm³ | $0.18 / cm³ | $0.25 / cm³ | +100 % |

| 50–200 cm³ | $0.14 / cm³ | $0.20 / cm³ | +100 % |

| 200–1,000 cm³ | $0.11 / cm³ | $0.16 / cm³ | +100 % |

| > 1,000 cm³ | Custom | Custom | Custom |

Section 4 — Case Studies

Case 1 — High-Resolution Camera Lens Barrel

Client: Smartphone OEM

Challenge: 14 mm Ø lens barrel, ±25 µm concentricity, clear optical path.

Workflow:

Client: Smartphone OEM

Challenge: 14 mm Ø lens barrel, ±25 µm concentricity, clear optical path.

Workflow:

-

Designed in SolidWorks, split into four threaded sections.

-

Printed in GP-Clear 25 µm layers.

-

CNC-turned M9 × 0.5 threads post-print.

-

Light-transmission test: 92 % @ 550 nm.

Lead time: 5 days vs. 6-week diamond-turned PMMA.

Case 2 — Custom Dental Surgical Guide

Client: Oral surgery clinic

Challenge: 8-implant guide, biocompatible, fit within 0.05 mm.

Solution:

Client: Oral surgery clinic

Challenge: 8-implant guide, biocompatible, fit within 0.05 mm.

Solution:

-

CBCT DICOM → Meshmixer → Onshape for sleeve bosses.

-

Printed in Bio-Med Clear, 50 µm.

-

Sterilized via autoclave 134 °C, 30 min.

Outcome: Reduced chair time by 35 %, zero re-prints.

Case 3 — Luxury Jewelry Master Pattern

Client: Milan atelier

Challenge: 18 k gold ring, filigree 0.3 mm, 30-piece limited run.

Workflow:

Client: Milan atelier

Challenge: 18 k gold ring, filigree 0.3 mm, 30-piece limited run.

Workflow:

-

Blender sculpt + ZBrush detailing.

-

Printed in Castable Purple, 25 µm.

-

Lost-wax cast in 18 k gold.

-

Surface Ra 0.4 µm straight from mold—no hand engraving.

Revenue: Sold out at €1,200 each.

Section 5 — Choosing Between SLA, DLP & FDM

| Scenario | SLA | DLP | FDM |

|---|---|---|---|

| < 0.3 mm features | ✓ | ✓ | ✗ |

| Transparent optics | ✓ | ○ | ✗ |

| 10+ cm³ volumes | Costly | Costly | Cheap |

| High-temp (>120 °C) | Limited | Limited | ✓ |

| ESD-safe | ✓ | ✓ | ✓ |

Section 6 — Sustainability & Bio-Resins

• Plant-based Bio-Med Clear reduces CO₂ by 35 %.

• IPA distillation unit recovers 94 % solvent.

• Failed prints cured into desk organizers—zero landfill.

• IPA distillation unit recovers 94 % solvent.

• Failed prints cured into desk organizers—zero landfill.

Section 7 — FAQ

Q: Can SLA parts be tapped?

A: Yes—print undersized by 0.1 mm and chase with tap; use Tough-X for durability.

A: Yes—print undersized by 0.1 mm and chase with tap; use Tough-X for durability.

Q: Maximum clear part thickness?

A: 5 mm before light scattering; above 5 mm use hollow with 1 mm walls.

A: 5 mm before light scattering; above 5 mm use hollow with 1 mm walls.

Q: Will clear resin yellow outdoors?

A: Add UV-block topcoat or switch to High-Temp Gray for outdoor use.

A: Add UV-block topcoat or switch to High-Temp Gray for outdoor use.

Ready to quote? Drag your STL into <url id=”d268lcnf2en4q1cioc4g”> and receive a live price, orientation preview, and free DFM report in minutes.