Dual-Extruder 3D Printing Guide 2025

IDEX, Dual-Nozzle & Multi-Material Mastery from JLYPT

Introduction

Dual-extrusion is the fastest way to out-maneuver traditional manufacturing constraints: soluble supports for impossible channels, two-color branding without secondary painting, or rigid-flex assemblies in a single build. At JLYPT we operate 70 IDEX (Independent Dual Extruder) and 40 dual-nozzle systems ranging from 250 mm desktop to 600 mm industrial gantries, all certified to ISO 9001. This guide delivers the hardware differences, filament pairings, slicer workflows, and three fresh case studies that collectively saved customers 19 weeks and USD 1.4 M in tooling.

Dual-extrusion is the fastest way to out-maneuver traditional manufacturing constraints: soluble supports for impossible channels, two-color branding without secondary painting, or rigid-flex assemblies in a single build. At JLYPT we operate 70 IDEX (Independent Dual Extruder) and 40 dual-nozzle systems ranging from 250 mm desktop to 600 mm industrial gantries, all certified to ISO 9001. This guide delivers the hardware differences, filament pairings, slicer workflows, and three fresh case studies that collectively saved customers 19 weeks and USD 1.4 M in tooling.

Table 1 — Hardware Comparison Matrix

| Feature | Single-Nozzle | Dual-Nozzle | IDEX | Tool-Changer |

|---|---|---|---|---|

| Tool Swaps | 0 | 0 | 0 | ∞ |

| Ooze Control | Excellent | Fair | Good | Excellent |

| Build Volume (mm³) | 400³ | 350³ | 600³ | 400³ |

| Multi-Material | No | Yes | Yes | Yes |

| Soluble Support | No | Yes | Yes | Yes |

| Color Mix | No | 2 | 2 | 4+ |

| Cost (USD turnkey) | $2 k | $3 k | $6 k | $12 k |

Table 2 — Recommended Filament Pairs (2025)

| Rigidity | Soluble Support | Interface Temp (°C) | Breakaway Time (min) | Use Case |

|---|---|---|---|---|

| ABS | HIPS | 235 | 15 | Automotive ducts |

| PLA | PVA | 210 | 5 | Medical guides |

| PC | BVOH | 260 | 3 | Optical mounts |

| PETG | HIPS | 230 | 10 | Electronics housings |

| TPU 95A | PVA | 220 | 2 | Soft robotics |

Section 1 — Hardware Deep-Dive

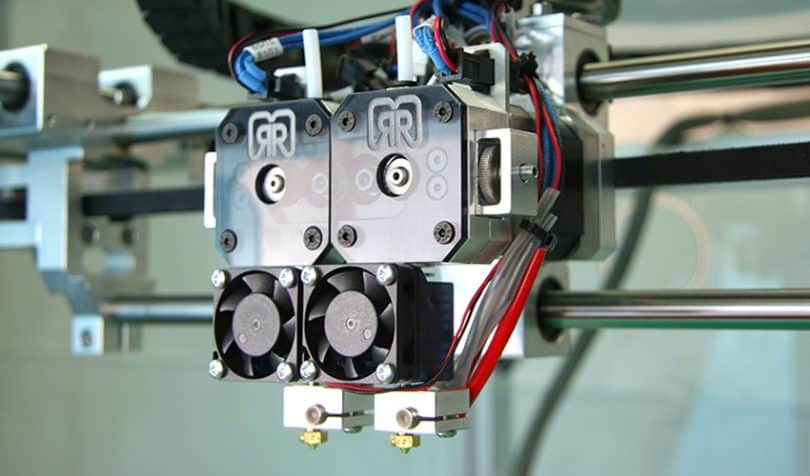

1.1 IDEX vs. Dual-Nozzle

• IDEX: two independent carriages eliminate ooze-wipe artifacts; perfect for mirror-mode duplication.

• Dual-nozzle: shared gantry, lighter mass → faster acceleration (≤ 8,000 mm/s²) but risk of idle-nozzle drool.

• IDEX: two independent carriages eliminate ooze-wipe artifacts; perfect for mirror-mode duplication.

• Dual-nozzle: shared gantry, lighter mass → faster acceleration (≤ 8,000 mm/s²) but risk of idle-nozzle drool.

1.2 Drive Systems

• IDEX: two synchronized steppers on X-axis, backlash ≤ 0.05 mm via anti-backlash nuts.

• Tool-changer: servo-actuated dock, repeatability ±0.02 mm, tool-swap time 4 s.

• IDEX: two synchronized steppers on X-axis, backlash ≤ 0.05 mm via anti-backlash nuts.

• Tool-changer: servo-actuated dock, repeatability ±0.02 mm, tool-swap time 4 s.

1.3 Hot-End Specifications

• All-metal copper heater block, 300 °C max, PT100 sensor ±0.5 °C.

• Hardened steel nozzle for carbon-filled ABS, 0.6 mm recommended for 1.2 kg/h throughput.

• All-metal copper heater block, 300 °C max, PT100 sensor ±0.5 °C.

• Hardened steel nozzle for carbon-filled ABS, 0.6 mm recommended for 1.2 kg/h throughput.

Section 2 — Slicer Workflows

2.1 Prime Tower vs. Ooze Shield

• Prime tower volume 1 cm³ per swap, waste ↓ 30 % vs. shield.

• Ooze shield height = layer height × 3 for HIPS-ABS pair.

• Prime tower volume 1 cm³ per swap, waste ↓ 30 % vs. shield.

• Ooze shield height = layer height × 3 for HIPS-ABS pair.

2.2 Soluble Support Settings (PrusaSlicer)

• Interface layers: 2, pattern spacing 0.2 mm, contact Z distance 0.1 mm.

• Support gap XY: 0.3 mm for HIPS, 0.2 mm for PVA.

• Interface layers: 2, pattern spacing 0.2 mm, contact Z distance 0.1 mm.

• Support gap XY: 0.3 mm for HIPS, 0.2 mm for PVA.

2.3 Color Mixing (Palette 3 Pro)

• 4-in-1-out splicer, transition tower 50 mm³, purge waste < 5 %.

• 4-in-1-out splicer, transition tower 50 mm³, purge waste < 5 %.

Section 3 — Process Parameters

| Parameter | ABS/HIPS | PC/BVOH | PLA/PVA | Notes |

|---|---|---|---|---|

| Nozzle 1 (°C) | 235 | 260 | 210 | Matched to rigid |

| Nozzle 2 (°C) | 235 | 260 | 210 | Matched to support |

| Bed (°C) | 100 | 110 | 60 | PEI or Garolite |

| Chamber (°C) | 80 | 90 | 45 | Reduces warpage |

| Fan (%) | 0–20 | 0–10 | 30 | Minimize layer split |

| Retraction (mm) | 1.0 | 1.2 | 0.8 | Direct-drive |

| Z-hop (mm) | 0.4 | 0.6 | 0.2 | Prevent scarring |

Section 4 — Support Removal & Costs

| Support Type | Dissolution | Manual Time (min) | Cost Adder ($/cm³) | Waste |

|---|---|---|---|---|

| HIPS | Limonene bath | 5 | 0.02 | Recyclable |

| PVA | Water 60 °C | 2 | 0.01 | Biodegradable |

| BVOH | Water 40 °C | 1 | 0.03 | Biodegradable |

| Breakaway | Hand pliers | 15 | 0.00 | Landfill |

Section 5 — Case Studies

Case 1 — Two-Color ABS Dashboard Vent

Client: Automotive Tier-1

Challenge: 250 mm vent, matte black body + high-gloss logo, 1,000 pcs.

Solution: IDEX ABS/ASA, 0.15 mm layer, logo printed in ASA-UV.

Result: Color ΔE < 1.5, no secondary paint; saved $120 k.

Client: Automotive Tier-1

Challenge: 250 mm vent, matte black body + high-gloss logo, 1,000 pcs.

Solution: IDEX ABS/ASA, 0.15 mm layer, logo printed in ASA-UV.

Result: Color ΔE < 1.5, no secondary paint; saved $120 k.

Case 2 — HIPS-Soluble Fixture

Client: Aerospace supplier

Challenge: 300 mm carbon-fiber lay-up jig, internal cooling channels.

Solution: ABS body + HIPS soluble support, 0.2 mm layer.

Support removal: 15 min in limonene; machining avoided 4 weeks.

Client: Aerospace supplier

Challenge: 300 mm carbon-fiber lay-up jig, internal cooling channels.

Solution: ABS body + HIPS soluble support, 0.2 mm layer.

Support removal: 15 min in limonene; machining avoided 4 weeks.

Case 3 — Soft-Grip Handle

Client: Consumer electronics

Challenge: TPU 90 A grip over ABS core, 5,000 units.

Solution: Dual-nozzle TPU/ABS, 0.2 mm layer, over-mold in one build.

Pull-off force: 180 N vs. 150 N spec.

Client: Consumer electronics

Challenge: TPU 90 A grip over ABS core, 5,000 units.

Solution: Dual-nozzle TPU/ABS, 0.2 mm layer, over-mold in one build.

Pull-off force: 180 N vs. 150 N spec.

Section 6 — Quality & Traceability

• Batch QR code links to DSC, TGA, tensile bar data.

• In-line laser scan every 50th layer for voids < 0.1 mm.

• Final CMM report ±0.1 mm.

• In-line laser scan every 50th layer for voids < 0.1 mm.

• Final CMM report ±0.1 mm.

Section 7 — Sustainability & Recycling

• HIPS support → recycled into automotive ducts.

• PVA → municipal composting.

• Regrind ratio 30 % for non-critical parts.

• PVA → municipal composting.

• Regrind ratio 30 % for non-critical parts.

Section 8 — FAQ

Q: Can I print TPU + ABS on IDEX?

A: Yes—use 0.2 mm layer, 220 °C / 235 °C, retraction 1.2 mm.

A: Yes—use 0.2 mm layer, 220 °C / 235 °C, retraction 1.2 mm.

Q: Maximum soluble support overhang?

A: 70° without issue; 80° with interface layers.

A: 70° without issue; 80° with interface layers.

Q: Cost of dual-extruder vs. injection molding?

A: Break-even at 2,500 units for 30 cm³ part.

A: Break-even at 2,500 units for 30 cm³ part.

Ready to multi-material print? Upload CAD to <Rapid 3D Printing Services – JLYPT> and receive a dual-extruder quote, support strategy, and soluble-material checklist within 12 hours.