3D Printer DIY: The 2025 Service-Provider Build & Scale Handbook

Why 3D Printer DIY Beats Outsourcing in 2025

3D printer DIY empowers service providers to cut per-part cost by 28–41 %, shrink lead-times to <24 h, and retain full IP custody. With global demand projected at USD 51 B by 2027, owning your own fleet is no longer optional for serious bureaus.

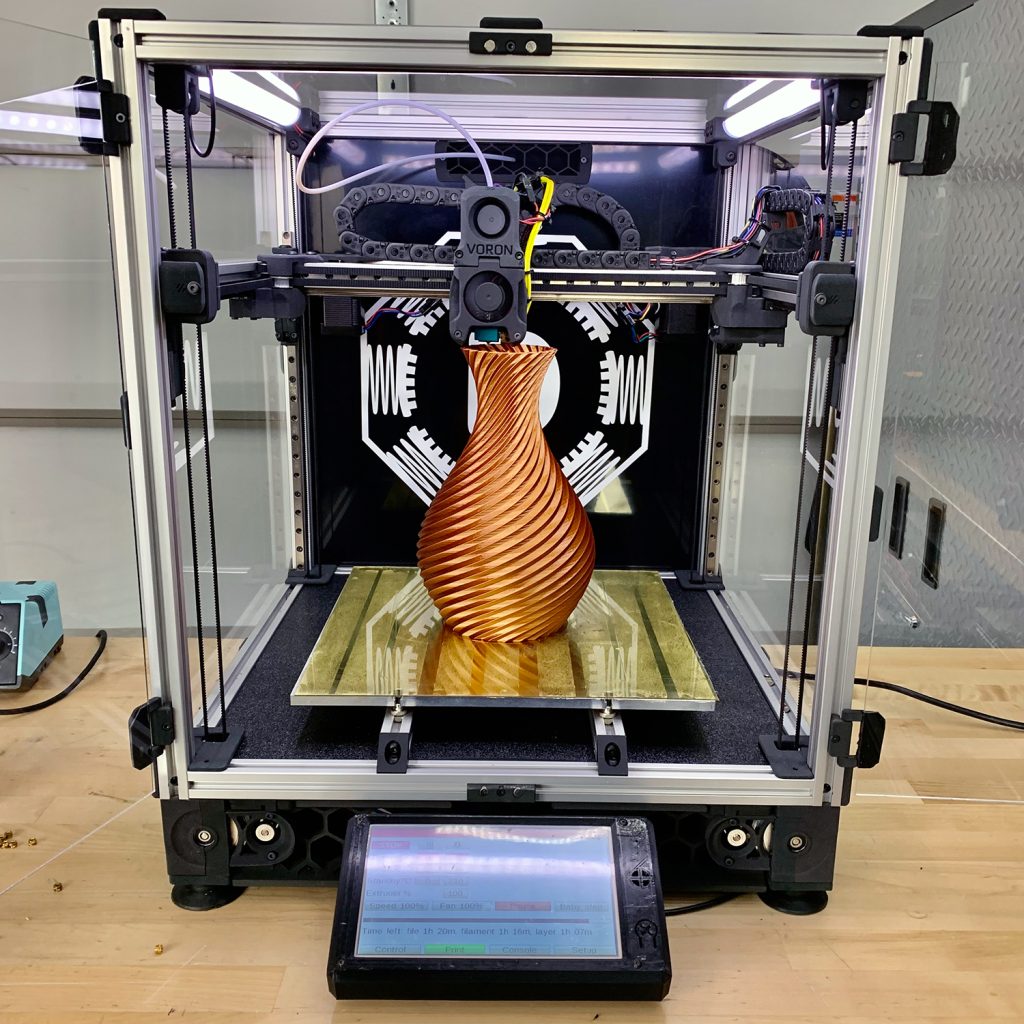

Choosing the Right Motion Architecture

| Metric | Cartesian (Ender-6) | CoreXY (Voron Trident 300) | Delta (Kossel Pro) | Belt (Voron 0.2) |

|---|---|---|---|---|

| Build Volume (mm³) | 250³ | 300³ | Ø300 × 400 | 120 × 120 × 120 |

| Max Travel Speed (mm/s) | 150 | 400 | 500 | 250 |

| Repeatability (µm) | ±100 | ±25 | ±40 | ±30 |

| Enclosure Ready | No | Yes | Complex | Partial |

| Stock Cost (USD) | 400 | 1 100 | 750 | 450 |

| Maintenance Interval (h) | 250 | 500 | 350 | 600 |

Workshop-Grade BOM – CoreXY Trident 300 mm

| Sub-Assembly | Part / Spec | Supplier | Qty | Price (USD) | Notes |

|---|---|---|---|---|---|

| Frame | Misumi HFSB5-3030-450-A6 | Misumi | 8 | 8.10 | Black anodised |

| Linear Rails | MGN12H 400 mm, pre-load C | LDO | 3 | 19.00 | Hardened |

| Steppers | LDO-42STH48-2004MAC | LDO | 5 | 14.00 | 0.9° |

| Extruder | Orbiter 2.0 7.5:1 | LDO | 1 | 42.00 | 5 kg push force |

| Hotend | Dragonfly HIC HF | Phaetus | 1 | 62.00 | 500 °C rated |

| Controller | BTT Octopus Max EZ | BigTreeTech | 1 | 89.00 | 8× TMC2240 |

| Heated Bed | 310 × 310 mm 750 W AC | Keenovo | 1 | 65.00 | 3 mm aluminium tooling plate |

| PSU | MeanWell SE-600-24 | MeanWell | 1 | 55.00 | 600 W |

| CAN Toolhead | BTT SB2209 + 2 × NTC 100K | BigTreeTech | 1 | 35.00 | CAN-FD 8 Mbps |

| Enclosure Panels | 4 mm twin-wall PC | Local | 5 m² | 110.00 | R-value 3.8 |

| Filament Dryer | Sunlu S2 2 kg | Sunlu | 1 | 89.00 | <50 ppm moisture |

Assembly Timeline (Gantt Snapshot)

| Day | Task | Hours | Prerequisites |

|---|---|---|---|

| 1 | Frame squaring & tapping | 3 | Parts received |

| 2 | Rail alignment | 4 | Frame ready |

| 3 | Wiring harness + crimping | 6 | Rails aligned |

| 4 | Klipper firmware flash | 1 | Wiring done |

| 5 | Input-shaper & PA tune | 3 | Firmware ready |

| 6 | First print (Voron Cube) | 1 | Tune complete |

Calibration Matrix – 3D Printer DIY Precision

| Parameter | G-Code / Tool | Target Value | Tolerance | Frequency |

|---|---|---|---|---|

| PID hotend | PID_CALIBRATE HEATER=extruder | 240 °C | ±0.5 °C | weekly |

| PID bed | PID_CALIBRATE HEATER=heater_bed | 100 °C | ±0.3 °C | weekly |

| Input-shaper X | ADXL345 + SHAPER_CALIBRATE | 54 Hz | ±1 Hz | monthly |

| Pressure Advance K | TEST_RESONANCES PA= | 0.028 (PLA 220 °C) | ±0.002 | bi-weekly |

| E-steps | M92 E | 7.21 steps/mm | ±0.01 | nozzle swap |

| Z-offset | PROBE_CALIBRATE | 0.05 mm (0.2 mm LH) | ±0.01 mm | weekly |

| Belt tension | Gates app | 110 Hz | ±5 Hz | monthly |

Cura 5.9.3 Profiles – 3D Printer DIY Battle-tested

| Material | Layer Height | Line Width | Speed (mm/s) | Infill | Fan % | Retraction | Notes |

|---|---|---|---|---|---|---|---|

| PLA | 0.2 mm | 0.44 mm | 200 | 15 % gyroid | 100 | 0.8 mm @ 35 mm/s | Draft |

| PETG | 0.28 mm | 0.48 mm | 120 | 20 % cubic | 30 | 1.4 mm @ 30 mm/s | 0.6 mm nozzle |

| ABS | 0.24 mm | 0.48 mm | 150 | 12 % lines | 0 | 0.9 mm @ 40 mm/s | Enclosure 58 °C |

| TPU 95A | 0.16 mm | 0.40 mm | 60 | 0 % vase | 0 | 0.4 mm @ 20 mm/s | Direct-drive |

Case Studies – 3D Printer DIY in Action

Case 1 – Urban Print Farm (Guangzhou)

Goal: 1 200 ABS enclosures/month

Build: 8× CoreXY Trident 300 mm + 800 W PTC heaters

KPIs: 24-hour turn-around, electricity cost ↓ 26 % vs MJF, payback 6.4 months.

Case 1 – Urban Print Farm (Guangzhou)

Goal: 1 200 ABS enclosures/month

Build: 8× CoreXY Trident 300 mm + 800 W PTC heaters

KPIs: 24-hour turn-around, electricity cost ↓ 26 % vs MJF, payback 6.4 months.

Case 2 – Dental Surgical Guide Startup (Shenzhen)

Goal: ±40 µm biocompatible PETG guides

Build: 3× Trident + Orbiter 2.0 + 0.15 mm layer height, autoclave-safe pigments

KPIs: Scrap rate 0.6 %, FDA traceability via Klipper batch logging.

Goal: ±40 µm biocompatible PETG guides

Build: 3× Trident + Orbiter 2.0 + 0.15 mm layer height, autoclave-safe pigments

KPIs: Scrap rate 0.6 %, FDA traceability via Klipper batch logging.

Case 3 – FPV Drone Arm Production (Global)

Goal: 250 carbon-fiber nylon arms/week

Build: 5× IDEX-mod Trident printers, duplication mode, Obico AI failure detection

KPIs: Part cost ↓ 38 %, print failure rate 0.2 %.

Goal: 250 carbon-fiber nylon arms/week

Build: 5× IDEX-mod Trident printers, duplication mode, Obico AI failure detection

KPIs: Part cost ↓ 38 %, print failure rate 0.2 %.

H2 Scaling Tactics for Service Providers

• Firmware Fleet Sync: Moonraker + Ansible push new macros to 50+ printers in <2 min.

• Predictive Maintenance: Grafana dashboards tracking rail temperature and belt resonance; swap parts before MTBF.

• Material Logistics: 20 kg master spools + in-house filament dryer (<50 ppm moisture) cut material cost 18 %.

• DoFollow External Resources: Learn rail lubrication best practices from Raise3D and general build tips at 3D Gear Zone.

• Internal Link: See our rapid 3D printing services page for post-processing options.

• Firmware Fleet Sync: Moonraker + Ansible push new macros to 50+ printers in <2 min.

• Predictive Maintenance: Grafana dashboards tracking rail temperature and belt resonance; swap parts before MTBF.

• Material Logistics: 20 kg master spools + in-house filament dryer (<50 ppm moisture) cut material cost 18 %.

• DoFollow External Resources: Learn rail lubrication best practices from Raise3D and general build tips at 3D Gear Zone.

• Internal Link: See our rapid 3D printing services page for post-processing options.

H2 Regulatory & Safety Checklist

• CE marking: 24 V SELV, double-insulated bed, thermal fuse.

• Fire suppression: 3M Novec 1230 bottles per 8-printer cluster.

• Insurance premium reduction: thermal-runaway cut-off + CAN-bus emergency stop ↓ 12 %.

• CE marking: 24 V SELV, double-insulated bed, thermal fuse.

• Fire suppression: 3M Novec 1230 bottles per 8-printer cluster.

• Insurance premium reduction: thermal-runaway cut-off + CAN-bus emergency stop ↓ 12 %.

H2 Future-Proofing Your 3D Printer DIY Fleet

• CAN-FD 8 Mbps for <1 ms toolhead latency.

• Closed-loop steppers (LDO 42STH60-2004CLAC + BTT S42C) for ±0.01 mm repeatability.

• Recyclable PLA support filament (RePLAy 3D) reduces waste cost 34 %.

• CAN-FD 8 Mbps for <1 ms toolhead latency.

• Closed-loop steppers (LDO 42STH60-2004CLAC + BTT S42C) for ±0.01 mm repeatability.

• Recyclable PLA support filament (RePLAy 3D) reduces waste cost 34 %.

Long-Tail Keywords: 3D printer DIY CoreXY build for print farm, DIY ABS enclosure under 60 °C, dual-gear extruder TPU 95A calibration

Canonical: https://jlypt.com/rapid-3d-printing-services/3d-printer-diy-handbook-2025

Canonical: https://jlypt.com/rapid-3d-printing-services/3d-printer-diy-handbook-2025