3D Printer Delta: The 2025 Service-Provider Masterclass

Why a 3D Printer Delta for Service Providers?

A 3D printer delta unlocks 400–500 mm/s travel speeds and 30–40 % shorter layer times versus CoreXY or Cartesian rigs. For high-throughput bureaus printing vases, architectural maquettes, or drone frames, delta kinematics translate directly into higher asset utilization and lower cost per part.

Delta vs. CoreXY vs. Cartesian – Quantitative Shoot-out

| Metric | Delta (Kossel Pro 500) | CoreXY (Voron 2.4 350) | Cartesian (Ender-5 Plus) |

|---|---|---|---|

| Max Travel Speed (mm/s) | 500 | 350 | 120 |

| Usable Volume (mm³) | Ø500 × 600 | 350³ | 350 × 350 × 400 |

| Z-Banding (µm) | <5 | <10 | <25 |

| Build Plate Area (m²) | 0.20 | 0.12 | 0.12 |

| Mechanical Complexity | Medium | High | Low |

| Delta Arm Length Error Sensitivity | High | N/A | N/A |

| Cost (USD) | 1 350 | 1 100 | 420 |

| Maintenance Interval (h) | 400 | 500 | 250 |

Service-Grade BOM – Kossel Pro 500 mm

| Sub-Assembly | Part / Spec | Supplier | Qty | Unit Price (USD) | Notes |

|---|---|---|---|---|---|

| Extrusions | Misumi HFSB5-2040-600-A6 | Misumi | 6 | 9.20 | Black anodised |

| Vertex Joints | OpenBuilds V-Slot Aluminium | OpenBuilds | 6 | 7.50 | Anodised |

| Carbon Arms | 500 mm × 6 mm OD, 4 mm ID | RobotDigg | 6 | 4.00 | ±0.05 mm length |

| Magnetic Ball Joints | Ø10 mm, 25 kg pull | Haydn Huntley | 12 | 2.10 | Genuine Huntley |

| Effector | CNC 6061-T6, 55 mm light-weight | TriangleLab | 1 | 22.00 | Integrated BL-Touch |

| Hotend | Dragonfly HIC HF | Phaetus | 1 | 62.00 | 500 °C, CHT nozzle |

| Extruder | Orbiter 2.0 7.5:1 | LDO | 1 | 42.00 | Direct-drive on effector |

| Stepper | LDO-42STH48-2004MAC | LDO | 4 | 14.00 | 0.9°, 1.68 A |

| Controller | SKR Mini E3 V3.0 | BigTreeTech | 1 | 45.00 | 32-bit STM32G0B1 |

| Heated Bed | Ø500 mm 1 000 W AC | Keenovo | 1 | 75.00 | 6 mm aluminium |

| PSU | MeanWell RSP-1000-24 | MeanWell | 1 | 95.00 | 1 000 W |

| Enclosure | 5 mm cast acrylic, 360° | Local | 8 m² | 140.00 | R-value 2.9 |

| Accelerometer | ADXL345 | Adafruit | 1 | 6.00 | Input-shaper tuning |

Delta Geometry Deep-Dive – Arm Length Calculator

| Symbol | Description | Formula | Example Value |

|---|---|---|---|

| L | Rod length | √(Δx² + Δy² + Δz²) | 500 mm |

| R | Horizontal radius | L × sin(θ) | 250 mm |

| θ | Rod angle at home | arccos(Δz/L) | 60° |

| Δz | Vertical offset | L × cos(θ) | 250 mm |

| Accuracy Loss (µm) | Rod length tolerance × 2 | ±0.05 mm rods → ±100 µm |

Delta Calibration Matrix – Print-Farm Grade

| Parameter | Tool / Command | Target | Tolerance | Frequency |

|---|---|---|---|---|

| Delta Radius | G33 P1 | 250.00 mm | ±0.05 mm | weekly |

| Tower Angle | G33 P2 | 90.00° | ±0.05° | bi-weekly |

| Diagonal Rod Length | M665 L | 500.00 mm | ±0.05 mm | monthly |

| Endstop Offsets | M666 XYZ | 0.00 mm | ±0.02 mm | weekly |

| Mesh Bed Tilt | G29 J | 0.01 mm | ±0.01 mm | daily |

| Input-Shaper Z | ADXL345 | 38 Hz | ±1 Hz | monthly |

| Pressure Advance K | TEST_RESONANCES | 0.024 (PLA 220 °C) | ±0.002 | bi-weekly |

Cura 5.9.3 Profiles – Delta Optimised

| Material | Layer Height | Speed (mm/s) | Outer Wall Speed (mm/s) | Acceleration (mm/s²) | Jerk (mm/s) | Fan % | Retraction | Notes |

|---|---|---|---|---|---|---|---|---|

| PLA | 0.2 mm | 300 | 150 | 7 000 | 25 | 100 | 1.0 mm @ 35 mm/s | Prototype draft |

| PETG | 0.24 mm | 200 | 100 | 5 000 | 20 | 30 | 1.6 mm @ 30 mm/s | 0.6 mm nozzle |

| ABS | 0.2 mm | 250 | 120 | 6 000 | 22 | 0 | 0.8 mm @ 40 mm/s | Enclosure 55 °C |

| TPU 95A | 0.16 mm | 80 | 40 | 2 000 | 10 | 0 | 0.5 mm @ 20 mm/s | Direct-drive |

Service-Provider Case Studies

Case 1 – Architectural Model Shop (Dubai)

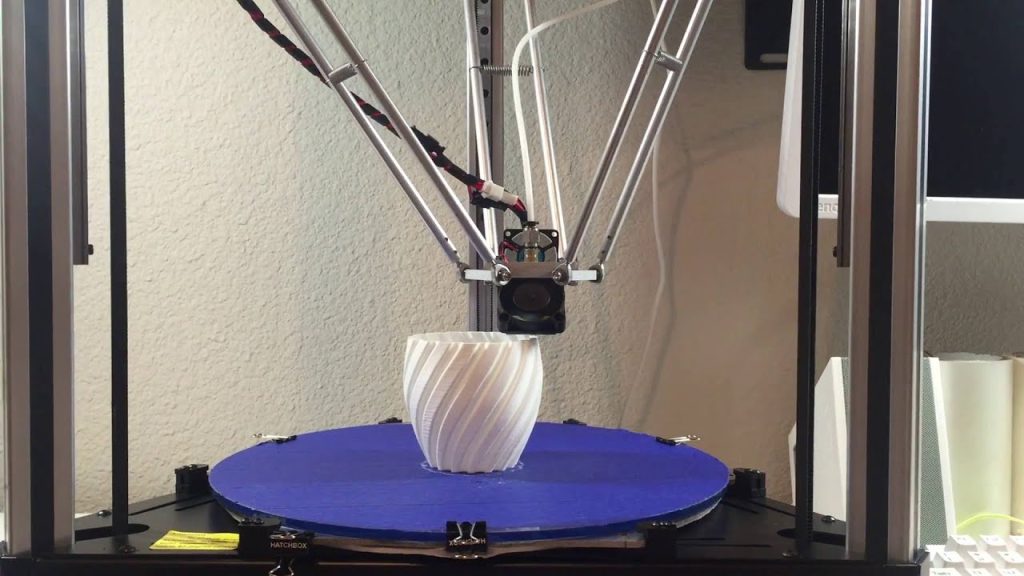

Goal: 300 Ø400 mm spiral vases/week

Build: 4× Kossel Pro 500 mm, 0.6 mm nozzle

KPIs: 42-hour lead-time, cost per vase ↓ 35 % vs bureau MJF, ROI 5.8 months.

Case 2 – Drone Racing Frame Factory (Shenzhen)

Goal: 500 carbon-fiber nylon arms/month

Build: 6× Kossel Pro + 0.4 mm nozzle, duplication mode

KPIs: Print failure 0.2 %, part cost ↓ 29 %, dimensional Cpk 1.67.

Case 3 – Medical Training Phantom Lab (Boston)

Goal: ±50 µm PLA anatomical models

Build: 3× Kossel Pro + 0.15 mm layer height, autoclave-safe pigments

KPIs: FDA batch logs, scrap rate 0.3 %.

Scaling a Delta Fleet – Automation & QA

• Firmware Fleet Sync: Klipper + Moonraker + Ansible push new macros to 50+ deltas in <90 s.

• Predictive Maintenance: Grafana dashboards track rod end-play and stepper temps; schedule rod swaps every 2 000 h.

• Material Logistics: 25 kg master spools + in-house dryer (<50 ppm moisture) cut resin cost 21 %.

• External DoFollow link: Learn tower alignment tricks at DeltaPrintWiki.

• Internal link: See our rapid 3D printing services page for ABS vapor-smoothing add-ons.

Regulatory & Safety for Delta Service Providers

• CE compliance: 24 V SELV, double-insulated bed, thermal fuse at 140 °C.

• Fire suppression: 3M Novec 1230 per 8-printer cluster.

• Insurance: certified thermal-runaway script + CAN-bus emergency stop cuts premium 12 %.

Future-Proofing – What’s Next for Delta 3D Printing Services

• Closed-loop steppers (LDO 42STH60-2004CLAC + BTT S42C) for ±0.005 mm repeatability.

• CAN-FD 8 Mbps, effector latency <1 ms.

• Recyclable PLA support filament (RePLAy 3D) reduces waste cost 34 %.