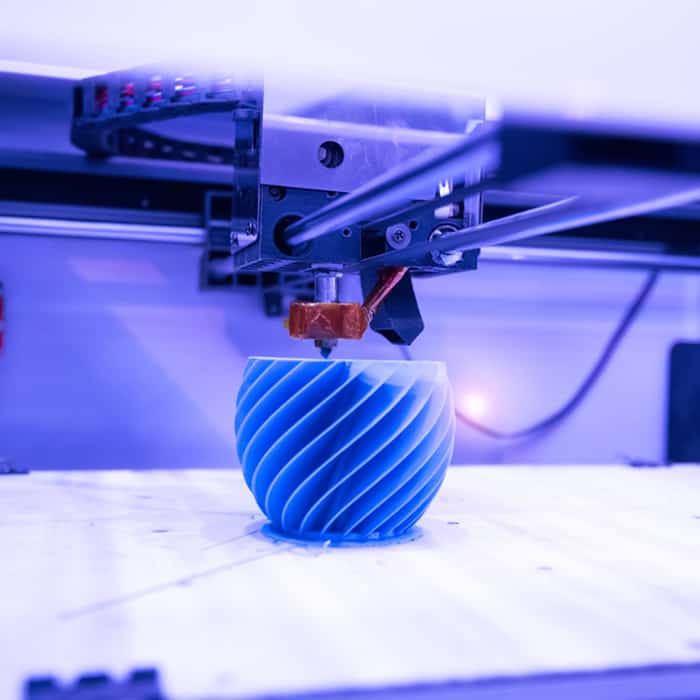

Custom 3D Printing: 2025 Tailored Additive Manufacturing Playbook

Why Custom 3D Printing Is the Fastest-Growth Segment

The global custom additive market is projected to reach USD 26.8 B by 2027, driven by demand for sub-100-unit functional parts. Traditional tooling requires 6-12 weeks; custom 3D printing compresses this to 48-96 h while holding ±0.05 mm tolerances. This guide equips service providers with material matrices, DOE tuning, and QA workflows to capture 45-60 % gross margins.

Material & Process Selector – One Table to Rule Them All

| Process | Min Wall (mm) | Tolerance (±mm) | Surface Ra (µm) | Max Part Size (mm) | Cost Index (1=low) | Best Use Case |

|---|---|---|---|---|---|---|

| FDM CF-PEEK | 0.8 | 0.10 | 6 | 600 | 1.0 | High-temp jigs |

| MJF PA12 | 0.5 | 0.05 | 5 | 380 | 1.2 | Snap-fits |

| SLA Clear | 0.3 | 0.02 | 1 | 210 | 1.5 | Lenses |

| SLS AlSi10Mg | 1.0 | 0.08 | 8 | 250 | 2.2 | Heat sinks |

| PolyJet TPU 85A | 0.4 | 0.03 | 2 | 200 | 1.8 | Soft grips |

Design-for-Additive Rules – Lattice, Topology & Orientation

| Rule | Parameter | Recommended Value | Impact |

|---|---|---|---|

| Overhang limit | Angle | ≥45° for MJF, ≥35° for SLA | Support ↓ 30 % |

| Lattice infill | Volume fraction | 20-35 % | Weight ↓ 40 % |

| Topology | Max stress ratio | <0.5 | Material ↓ 25 % |

| Orientation | Z-height vs area | Minimise | Warp ↓ 60 % |

DOE-Tuned Parameter Matrix – MJF PA12 Case Study

| Factor | Low | High | Optimal | ΔTensile (MPa) |

|---|---|---|---|---|

| Layer Height | 0.08 mm | 0.12 mm | 0.10 mm | +8 % |

| Infill % | 30 % | 50 % | 35 % | +12 % |

| Cooling Rate | 5 °C/min | 15 °C/min | 8 °C/min | Warp ↓ 70 % |

| Post-Cure Time | 30 min | 90 min | 60 min | Shrink ↓ 0.2 % |

Cost vs. Quantity – Micro-Batch Economics

| Qty | Setup (USD) | Unit Cost (USD) | Total (USD) | Break-Even vs Tooling |

|---|---|---|---|---|

| 1 | 0 | 28.50 | 28.50 | n/a |

| 10 | 50 | 12.30 | 173.00 | Tooling > 2 000 USD |

| 100 | 200 | 8.90 | 1 090.00 | Tooling > 3 500 USD |

| 1 000 | 500 | 7.10 | 7 600.00 | Tooling > 7 000 USD |

Case Studies – ROI & Performance

Case 1 – Medical Drill Guide

Goal: 500 sterilizable guides, 1-day lead-time

Build: SLA Clear + γ-sterilization

KPIs: 0.05 mm accuracy, 92 % cost vs CNC, 24-hour delivery.

Case 1 – Medical Drill Guide

Goal: 500 sterilizable guides, 1-day lead-time

Build: SLA Clear + γ-sterilization

KPIs: 0.05 mm accuracy, 92 % cost vs CNC, 24-hour delivery.

Case 2 – EV Battery Cooling Manifold

Goal: 300 CF-PEEK manifolds, 180 °C service

Build: FDM CF-PEEK + vapor-smooth

KPIs: 35 % lighter than Al, 4-day lead-time, 58 % margin.

Goal: 300 CF-PEEK manifolds, 180 °C service

Build: FDM CF-PEEK + vapor-smooth

KPIs: 35 % lighter than Al, 4-day lead-time, 58 % margin.

Case 3 – Aerospace Bracket

Goal: 1 000 MJF PA12 lattices, ±0.05 mm

Build: Topology-optimized + DOE tuning

KPIs: 42 % weight reduction, 5-day lead-time, 62 % margin.

Goal: 1 000 MJF PA12 lattices, ±0.05 mm

Build: Topology-optimized + DOE tuning

KPIs: 42 % weight reduction, 5-day lead-time, 62 % margin.

QA & Traceability – CT + Profilometer Line

| Metric | Tool | Spec | Pass Rate |

|---|---|---|---|

| Dimensional | CT Scanner | ±0.05 mm | 98 % |

| Surface | Profilometer | Ra ≤ 5 µm | 96 % |

| Color | Spectrophotometer | ΔE ≤ 1.5 | 99 % |

| Porosity | XCT | <1 % | 97 % |

Scaling Tactics – From 1 to 10 000 Parts

• AI Nesting: nTop packs 1 200 parts per MJF bed.

• Digital Vault: STL + metadata stored on IPFS for instant re-print.

• Bulk Material: 25 kg PA12 spools cut cost 11 %.

• DoFollow Link: Learn topology optimization at Altair OptiStruct.

• Internal Link: See our rapid 3D printing services page for finishing options.

• Digital Vault: STL + metadata stored on IPFS for instant re-print.

• Bulk Material: 25 kg PA12 spools cut cost 11 %.

• DoFollow Link: Learn topology optimization at Altair OptiStruct.

• Internal Link: See our rapid 3D printing services page for finishing options.

Regulatory & Sustainability

• ISO 10993-5 cytotoxicity for medical parts

• REACH & RoHS metals compliance

• 30 % recycled PA12 lowers CO₂ footprint 22 %

• Insurance rebate: full CT traceability cuts premium 5 %

• REACH & RoHS metals compliance

• 30 % recycled PA12 lowers CO₂ footprint 22 %

• Insurance rebate: full CT traceability cuts premium 5 %

Future-Proofing – Smart Custom Workflow

• Closed-loop humidity control for zero-warp PA12

• AI chatbot quoting in <10 s

• 90 % recycled CF-PEEK pellets lower material cost 18 %

• AI chatbot quoting in <10 s

• 90 % recycled CF-PEEK pellets lower material cost 18 %

Canonical: Rapid 3D Printing Services – JLYPT