The Ultimate Guide to CNC Machining Services for Titanium Parts

Introduction

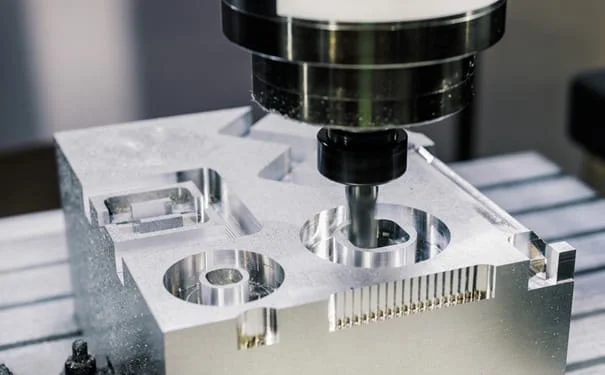

Titanium stands as one of the most challenging yet rewarding materials in the realm of CNC machining. Its exceptional strength-to-weight ratio, outstanding corrosion resistance, and biocompatibility make it indispensable across aerospace, medical, and high-performance industrial applications. However, these same properties demand specialized expertise, equipment, and processes to machine effectively. This comprehensive guide explores the intricacies of CNC machining services for titanium parts, detailing the technical processes, material considerations, applications, and how to select a partner capable of meeting the exacting standards required for success.

Why Titanium? Properties and Challenges

Titanium alloys, particularly Ti-6Al-4V (Grade 5), which constitutes about 50% of total titanium usage, offer a unique combination of properties:

-

High Strength-to-Weight Ratio: Titanium offers strength comparable to many steels at about 45% less weight.

-

Excellent Corrosion Resistance: It forms a protective oxide layer that resists corrosion in harsh environments.

-

Biocompatibility: Certain grades are non-toxic and compatible with the human body, ideal for medical implants.

-

High Temperature Resistance: Retains strength at elevated temperatures where many aluminum alloys fail.

However, these benefits come with significant machining challenges:

-

Low Thermal Conductivity: Heat generated during cutting doesn’t dissipate easily, concentrating on the tool edge and leading to rapid tool wear and potential workpiece damage.

-

Chemical Reactivity: At high temperatures, titanium reacts with tool coatings, leading to galling, adhesion, and built-up edge.

-

High Strength at Elevated Temperatures: Titanium maintains its strength even as cutting temperatures rise, requiring robust machining strategies.

Specialized CNC Machining Techniques for Titanium

Overcoming these challenges requires a meticulous approach to machining, leveraging advanced technology and proven techniques.

1. Machine Tool Requirements

Machining titanium demands high-rigidity machining centers capable of maintaining stability under high cutting forces. 5-axis CNC machines are particularly valuable for complex aerospace and medical components, allowing for continuous machining of intricate geometries in a single setup. These machines often feature:

-

Robust Construction: Mineral cast beds and large-diameter ball screws enhance damping and reduce vibration.

-

High-Pressure Coolant Systems: Essential for evacuating chips and managing thermal growth.

-

High-Torque Spindles: Capable of maintaining stable cutting speeds in demanding conditions.

2. Tooling Selection and Geometry

The choice of cutting tool is critical for titanium. Carbide tools with specialized geometries are standard:

-

Grade: Micro-grain carbide substrates offer the best balance of toughness and wear resistance.

-

Geometry: Sharp cutting edges, positive rakes, and reduced contact areas help minimize heat generation and prevent work hardening.

-

Coatings: PVD (Physical Vapor Deposition) coatings like AlTiN (Aluminum Titanium Nitride) provide enhanced lubricity and thermal barriers.

3. Cutting Parameters and Strategies

Optimized parameters are non-negotiable for titanium:

-

Surface Speed (SFM): Conservative speeds are used to manage heat (e.g., 50-110 SFM for roughing, up to 200 SFM for finishing with specific tools).

-

Feed Rate: Maintaining an adequate chip load per tooth is crucial to prevent rubbing and work hardening, often employing trochoidal milling or peck drilling strategies.

-

Depth of Cut: Higher axial depths of cut and lower radial engagements are often preferred to engage more of the tool’s flute length, improving heat dissipation into the chip and away from the tool.

Table: Comparison of Titanium Alloys for CNC Machining

| Alloy Grade | Common Name | Key Properties | Primary Applications | Machinability Rating |

|---|---|---|---|---|

| Grade 1 | Commercially Pure | Highest ductility, excellent corrosion resistance | Chemical processing, marine applications | Good |

| Grade 2 | Commercially Pure | Standard purity, good balance of strength/ductility | Aerospace, medical, automotive | Good |

| Grade 5 | Ti-6Al-4V | Most common alloy, high strength | Aerospace frames, medical implants, engine parts | Fair (Most Machined) |

| Grade 23 | Ti-6Al-4V ELI | Extra Low Interstitial, higher fracture toughness | Medical implants, aerospace critical components | Fair |

| Ti-6Al-2Sn-4Zr-2Mo | Ti-6242 | Excellent high-temperature strength & creep resistance | Jet engine components, high-temp applications | Difficult |

4. Cooling and Lubrication

High-Pressure Through-Spindle Coolant (TSC) is highly recommended. It serves two vital functions:

-

Thermal Management: Floods the cut zone to remove heat.

-

Chip Evacuation: Blasts chips away from the cutting edges, preventing recutting and tool damage.

Applications of CNC Machined Titanium Parts

The unique properties of machined titanium make it critical in several high-stakes industries.

Table: Applications of CNC Machined Titanium Components by Industry

| Industry | Example Components | Why Titanium? | Critical Requirements |

|---|---|---|---|

| Aerospace | Structural airframe components, engine mounts, turbine blades, landing gear parts | High strength-to-weight, corrosion resistance, fatigue strength | Stringent certification (AS9100), high fatigue life, complex geometries |

| Medical | Hip and knee implants, spinal fusion cages, surgical instruments, bone screws | Biocompatibility, osseointegration, MRI compatibility, strength | ISO 13485 certification, exceptional surface finishes, micromachining |

| Defense | Armor components, vehicle structures, guidance system housings, weapon systems | Lightweight for mobility, durability in harsh environments | High durability, compliance with military specs (MIL specs), reliability |

| Automotive | Connecting rods, valve springs, exhaust systems, racing components (F1) | Weight reduction for performance and efficiency, high-temperature strength | High-volume production capability, cost-effectiveness |

| Industrial | Marine components, chemical processing valves and pumps, MRO parts | Superior corrosion resistance in extreme environments | Corrosion resistance certification, precise sealing surfaces |

Quality Assurance and Metrology

Consistent quality in titanium machining is verified through rigorous inspection protocols, often adhering to ISO 9001 and AS9100 (aerospace) standards. Key metrology equipment includes:

-

Coordinate Measuring Machines (CMM): For precise dimensional analysis of complex geometries.

-

Optical Comparators & Vision Systems: For rapid 2D profile inspection.

-

Surface Roughness Testers: To verify critical surface finishes.

-

Spectrometers: For material composition verification.

Case Studies: Precision Titanium Machining in Action

Case Study 1: Aerospace Turbine Blade

-

Challenge: Produce 500 titanium turbine blades with a surface finish of Ra 0.4μm within an 8-week delivery window. A local supplier quoted $1,200 per part with uncertain lead times.

-

Solution: A 5-axis CNC machining provider optimized tool paths and implemented a high-pressure cooling solution specifically designed for titanium’s low thermal conductivity.

-

Results: Achieved a 46% cost reduction ($650/part), shortened lead time to 6 weeks, and maintained a defect rate below 0.1%, fully meeting the stringent aerospace performance criteria.

Case Study 2: Medical Joint Implant

-

Challenge: Machine a biocompatible Ti-6Al-4V ELI (Grade 23) implant with complex porous structures for bone ingrowth, requiring micron-level accuracy and a mirror-like surface finish to prevent bacterial adhesion.

-

Solution: Utilized 5-axis micromachining with specialized, polished carbide end mills. The process was optimized with adjusted rpm and feed rates for titanium, and incorporated cryogenic cooling to preserve material properties and achieve the required surface finish without compromising the metallurgical integrity of the implant.

-

Results: The components exceeded all medical specifications, achieving 99.8% dimensional compliance and surface finishes better than Ra 0.2μm, enabling successful surgical outcomes and long-term implant performance.

Case Study 3: Russian Aerospace Component Technical Support

-

Challenge: A Russian aerospace manufacturer faced production delays due to thermal expansion issues causing precision instability when machining high-precision titanium components on their five-axis machining center.

-

Solution: A technical team from the machine tool provider (e.g., a scenario like Hui Hou of Fenghui Mold leading a team) conducted on-site troubleshooting. They performed a systematic investigation and implemented a comprehensive solution involving “process path optimization + cooling scheme upgrade.” This included adjusting tool trajectory compensation parameters and improving a segmented coolant喷射 strategy.

-

Results: The solution effectively controlled temperature fluctuations in the machining area, eliminated thermal deformation interference on precision, and restored the production line to full capacity operation. This on-site support not only resolved the immediate issue but also optimized the entire machining process, significantly enhancing工艺稳定性 (process stability).

Selecting a CNC Machining Partner for Titanium Parts

Choosing the right supplier is critical. Key factors to consider include:

-

Technical Expertise & Experience: Look for a proven track record with titanium in your specific industry (aerospace, medical, etc.).

-

Advanced Equipment: Ensure they possess modern, rigid 5-axis CNC machines equipped with high-pressure coolant systems.

-

Quality Certifications: Verify relevant certifications like ISO 9001:2015, AS9100D (Aerospace), and ISO 13485 (Medical).

-

Comprehensive Quality Control: The partner should have in-house metrology lab with CMMs and other inspection gear to verify part quality.

-

Design for Manufacturability (DFM) Feedback: A good partner will provide expert DFM analysis to optimize your design for cost-effective titanium machining.

-

Supply Chain Reliability: Assess their ability to source genuine titanium raw materials and manage programs efficiently.

The Future of Titanium CNC Machining

The field continues to evolve with several key trends:

-

Advanced Automation: Integration of robotics for unattended machining, crucial for managing the longer cycle times associated with titanium.

-

Digital Twin & IoT: Using real-time data from machine sensors to create digital models of the machining process, allowing for predictive adjustments and further quality optimization.

-

Hybrid Manufacturing: Combining additive manufacturing (3D printing) to create near-net-shape titanium preforms with CNC machining to achieve final precision. This approach minimizes material waste—a significant cost factor with titanium.

-

Sustainable Machining: Adoption of Minimum Quantity Lubrication (MQL) and other techniques to reduce environmental impact.

Conclusion

CNC machining of titanium parts sits at the apex of manufacturing, demanding a sophisticated blend of advanced technology, deep material knowledge, and unwavering precision. While the challenges are significant—from managing heat to ensuring tool longevity—the rewards are unparalleled performance in the world’s most demanding applications.

Success hinges on partnering with a CNC service provider that possesses not just the right equipment, but the proven expertise and quality systems to transform this exceptional material into reliable, high-performance components. By understanding the intricacies outlined in this guide, you can make informed decisions that ensure your titanium machining projects meet the highest standards of precision, quality, and performance.