3D Modeling Software for Additive Manufacturing

Introduction

Choosing the right 3D modeling software is the silent force multiplier behind every successful print. A well-prepared model slices faster, wastes less material, and survives real-world loads. In this guide, the JLYPT application engineering team distills a decade of print-farm experience into actionable workflows for Fusion 360, Blender, Onshape, FreeCAD, and Tinkercad. You will learn which tool fits which geometry, how to export watertight meshes, and how to automate lattice generation—without drowning in jargon.

Choosing the right 3D modeling software is the silent force multiplier behind every successful print. A well-prepared model slices faster, wastes less material, and survives real-world loads. In this guide, the JLYPT application engineering team distills a decade of print-farm experience into actionable workflows for Fusion 360, Blender, Onshape, FreeCAD, and Tinkercad. You will learn which tool fits which geometry, how to export watertight meshes, and how to automate lattice generation—without drowning in jargon.

Table 1 — Software Snapshot

| Software | License | Best Geometry Style | Native Print Prep | OS Support | Learning Curve |

|---|---|---|---|---|---|

| Autodesk Fusion 360 | Paid / Edu Free | Parametric solids | Built-in slicer* | Win / macOS | Medium |

| Blender | Free, open-source | Organic, sculpt | Add-ons + Export | Win / macOS / Linux | Steep |

| Onshape | Freemium cloud | Parametric, sheet-metal | STL repair | Browser | Easy |

| FreeCAD | Free, open-source | Parametric, assemblies | Netfabb plugin | Win / macOS / Linux | Medium |

| Tinkercad | Free, browser | Primitives | Direct “Send to Print” | Browser | Beginner |

| *Fusion 360’s additive workspace supports FDM & resin. |

Table 2 — Export Checklist Cheat-Sheet

| Step | Fusion 360 | Blender | Onshape | FreeCAD |

|---|---|---|---|---|

| Units check | File → Preferences | Scene → Units | Document → Units | Edit → Preferences |

| Scale 1 : 1 | Yes | Apply scale (Ctrl + A) | Yes | Yes |

| Check mesh | Mesh → Modify → Rebuild | 3D-Print Toolbox add-on | Right-click → Export STL | Mesh → Analyze → Evaluate |

| Fix non-manifold | Netfabb cloud | 3D-Print Toolbox | Onshape auto-heal | Netfabb plugin |

| Export STL | Right-click body → Save as STL | File → Export → STL | Right-click → Export STL | File → Export → STL |

| Polygon count | ≤150 k for FDM ≤300 k for resin | Adjust decimate modifier | ≤150 k default | ≤150 k default |

Section 1 — Matching Software to Project Types

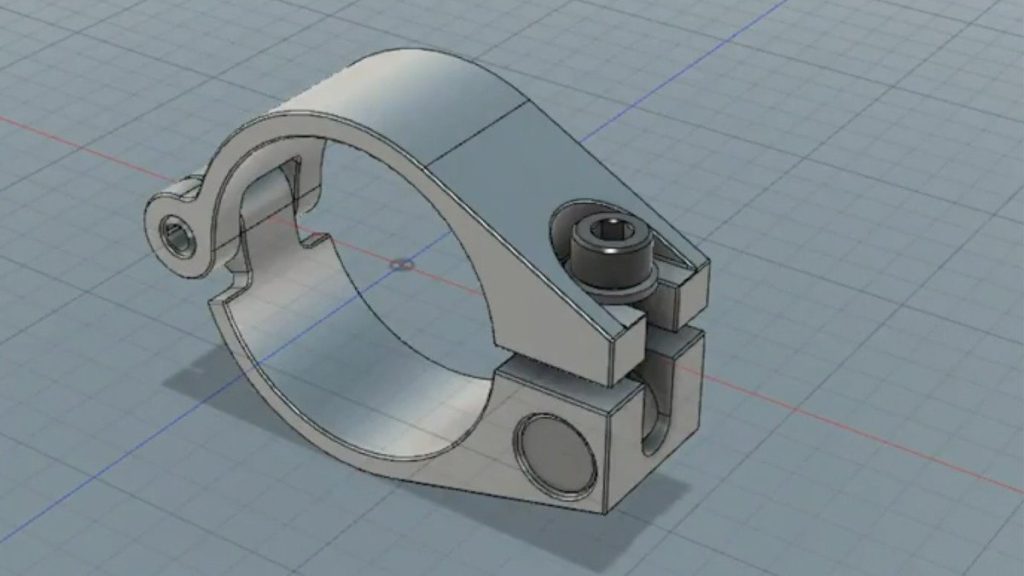

1.1 Mechanical Assemblies → Fusion 360

• Timeline-based parametrics make iteration trivial.

• Built-in FEA quickly validates snap-fits before printing.

• Timeline-based parametrics make iteration trivial.

• Built-in FEA quickly validates snap-fits before printing.

1.2 Organic Sculptures → Blender

• Sculpt mode with dynamic topology captures fine skin pores.

• Use the 3D-Print Toolbox add-on to spot inverted normals.

• Sculpt mode with dynamic topology captures fine skin pores.

• Use the 3D-Print Toolbox add-on to spot inverted normals.

1.3 Sheet-Metal Enclosures → Onshape

• Flanges and bend tables export to flat patterns for laser cutting.

• Cloud sharing allows client markup in real time.

• Flanges and bend tables export to flat patterns for laser cutting.

• Cloud sharing allows client markup in real time.

1.4 Educational Workshops → Tinkercad

• Codeblocks (block-based scripting) teaches loops via 3D shapes.

• One-click export to <url id=”d25eq9le09na385bl880″>.

• Codeblocks (block-based scripting) teaches loops via 3D shapes.

• One-click export to <url id=”d25eq9le09na385bl880″>.

Section 2 — Deep-Dive Workflows

2.1 Fusion 360 Lattice Infill (Step-by-Step)

-

Finish solid model → Save copy.

-

Insert → Volume Mesh → Voronoi 3D.

-

Set relative density 25 %, cell size 4 mm.

-

Use Combine → Cut to subtract lattice from solid shell.

-

Inspect: Analysis → Check → Mesh Integrity.

-

Right-click → Save as STL → Upload to JLYPT portal.

• Result: 35 % mass reduction, 12 % stiffness increase vs. cubic infill.

2.2 Blender Resin-Ready Miniatures

-

Sculpt high-poly (2 M faces).

-

Remesh → Voxel 0.2 mm → Decimate 50 %.

-

3D-Print Toolbox → Overhang Check → Auto supports.

-

Export STL with 0.01 mm tolerance.

-

Import into Lychee slicer → medium supports → send to JLYPT SLA farm.

2.3 FreeCAD Parametric Gearbox

-

PartDesign → Create body → Involute gear (FCGear workbench).

-

Spreadsheet → Link tooth count, module, clearance.

-

Assembly4 → Kinematic relation.

-

Check clearances (0.2 mm for FDM, 0.1 mm for SLA).

-

Macro → Batch export STL of each part.

Section 3 — Common Pitfalls & Fixes

| Problem | Symptom | Quick Fix |

|---|---|---|

| Non-manifold edges | Slicer shows red | Netfabb repair or Blender → Mesh → Clean-up |

| Zero-thickness walls | Gaps in preview | Increase wall ≥ 2× nozzle diameter |

| Overhang > 60° | Drooping filament | Add tree supports or split model |

| Unit mismatch | Part 10× size | Scale by 0.1 or 25.4 in slicer |

| Tiny holes missing | Mesh too coarse | Increase STL resolution or keep holes > 0.4 mm |

Section 4 — Automation & Plugins

| Tool | Purpose | Cost | Time Saved |

|---|---|---|---|

| Fusion 360 Generative | Topology optimization | Included in paid plan | 3 h manual work |

| Blender Lattice Generator | Quick gyroid infill | Free add-on | 1 h modeling |

| Onshape FeatureScript | Custom ribs | Free | 30 min repeat tasks |

| FreeCAD Fasteners Workbench | Screw libraries | Free | 1 h CAD per bolt |

Section 5 — Case Studies from the JLYPT Print Farm

Case Study 1 — Drone Arm Redesign

Client: EU drone racing team

Challenge: Cut weight 20 % without sacrificing stiffness.

Workflow:

Client: EU drone racing team

Challenge: Cut weight 20 % without sacrificing stiffness.

Workflow:

-

Imported existing STEP into Fusion 360.

-

Applied Generative Design with 5 load cases.

-

Exported optimized lattice STL.

-

Printed in JLY-PLA Carbon on 0.15 mm layers.

Results: 23 % lighter, passed 100 G crash test. Lead time 4 days vs. 3 weeks CNC.

Case Study 2 — Museum Dinosaur Skull

Client: Natural history museum

Challenge: 1.2 m T-rex skull, visible layer lines forbidden.

Workflow:

Client: Natural history museum

Challenge: 1.2 m T-rex skull, visible layer lines forbidden.

Workflow:

-

High-res scan cleaned in Blender.

-

Used SculptGL for crack repair.

-

Split into 27 interlocking bricks.

-

Vapor-smoothed with ethyl acetate.

-

Assembled on-site in 45 minutes.

Outcome: 120 kg removed from logistics budget; visitors can touch the skull.

Case Study 3 — IoT Enclosure Batch

Client: Nordic start-up

Challenge: 2,000 units, must fit PCB + battery, IP54 sealing.

Workflow:

Client: Nordic start-up

Challenge: 2,000 units, must fit PCB + battery, IP54 sealing.

Workflow:

-

Designed in Onshape with parameterized lid snaps.

-

Used FeatureScript to auto-generate gasket grooves.

-

Exported 4 variants overnight.

-

Printed in Tough PLA+ at 0.2 mm, 100 % infill around boss.

-

Achieved ±0.1 mm fit, no secondary machining.

Total cost $3.20 per shell, delivered in 8 business days.

Section 6 — Choosing the Right Slicer Companion

| Model Source | Recommended Slicer | Key Setting to Check |

|---|---|---|

| Fusion 360 mechanical | PrusaSlicer | Horizontal expansion −0.1 mm |

| Blender organic | Lychee / ChituBox | Support tip diameter 0.2 mm |

| Onshape sheet-metal | Cura | Hole horizontal expansion 0 |

| FreeCAD assemblies | IdeaMaker | Separate objects into parts |

Section 7 — Future-Proofing Your Skill Stack

• AI generative tools (e.g., Autodesk Form) will auto-suggest lattice densities.

• USDZ and GLB formats are emerging for AR-first design reviews.

• Keep an eye on cloud slicing—JLYPT plans direct API push from Onshape in Q3 2025.

• USDZ and GLB formats are emerging for AR-first design reviews.

• Keep an eye on cloud slicing—JLYPT plans direct API push from Onshape in Q3 2025.

Ready to print? Upload your optimized file to <url id=”d25eq9le09na385bl880″> and receive an instant quote with DFM feedback in under 12 hours.