The Complete Guide to 5-Axis CNC Machining for Complex Components

Executive Summary

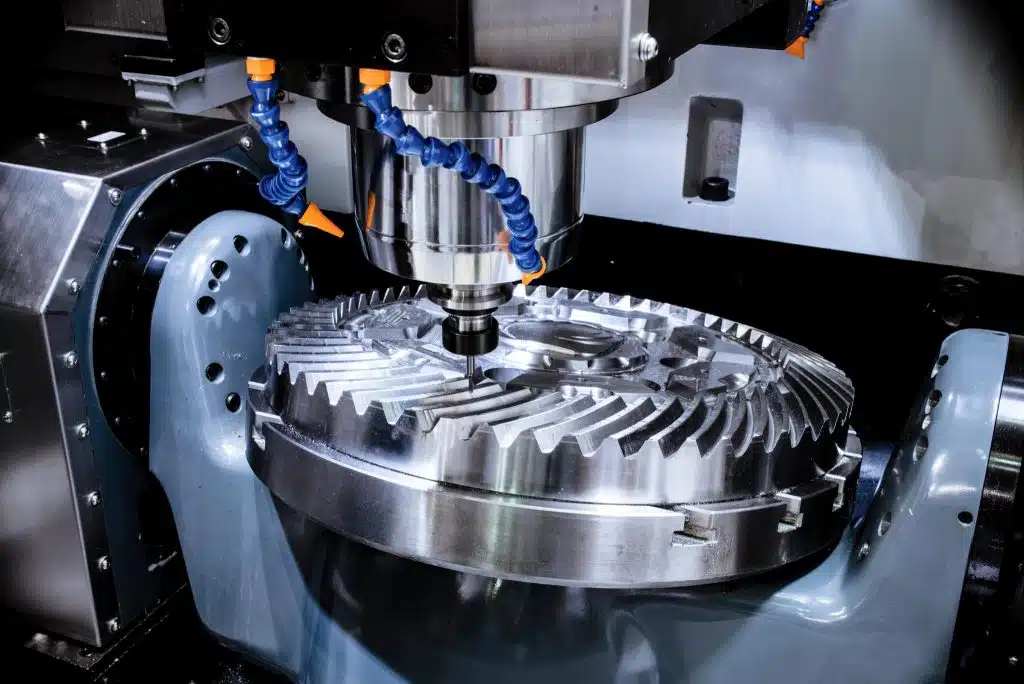

5-axis CNC machining represents the pinnacle of manufacturing technology for producing complex geometric parts with exceptional precision and efficiency. This advanced manufacturing approach enables simultaneous movement along five different axes, allowing for the creation of intricate components that would be impossible or economically unviable with traditional 3-axis machining. The technology has revolutionized industries ranging from aerospace and defense to medical devices and high-performance automotive applications, where complex geometries, tight tolerances, and superior surface finishes are paramount. This comprehensive guide explores the technical capabilities, applications, and advantages of 5-axis CNC machining for complex parts, providing engineering professionals and manufacturing decision-makers with the insights needed to leverage this technology for their most challenging component requirements.

1 Introduction to 5-Axis CNC Machining Technology

5-axis CNC machining involves the use of computer numerical control systems to simultaneously move cutting tools or workpieces along five different axes. This advanced manufacturing technology typically incorporates three linear axes (X, Y, and Z) and two rotational axes (A and B, or A and C, depending on machine configuration). The simultaneous movement capability allows the cutting tool to maintain optimal orientation to the workpiece surface, enabling the production of complex geometries with exceptional precision and surface quality.

The fundamental advantage of 5-axis machining lies in its ability to complete complex parts in a single setup, eliminating the cumulative errors that occur when moving parts between multiple machines or repositioning them in different fixtures. This capability is particularly valuable for manufacturing components with compound curves, undercuts, complex contours, and features that require machining from multiple angles. Industries such as aerospace, medical, and energy regularly utilize 5-axis machining for components where design complexity meets stringent performance requirements.

Modern 5-axis machining centers incorporate advanced features such as high-speed spindles (reaching 10,000-30,000 RPM), precision ball screws and roller guideways for accurate positioning, and hydraulic disc brakes on rotational axes to maintain stability during heavy cutting operations. These systems often include automatic tool changers with capacities ranging from 30 to 120+ tools, allowing for uninterrupted machining of complex parts requiring multiple operations and tool types.

2 Technical Advantages of 5-Axis Machining for Complex Parts

The implementation of 5-axis machining technology provides numerous technical advantages for manufacturing complex components:

Single Setup Manufacturing: The most significant advantage of 5-axis machining is the ability to complete even the most complex parts in a single setup. This eliminates the accumulated误差 that occurs when moving parts between multiple machines or repositioning them in different fixtures. For precision components, this can improve overall accuracy by 30-50% compared to multi-setup manufacturing approaches.

Superior Surface Finish: By maintaining the cutting tool perpendicular to the workpiece surface throughout complex contours and curves, 5-axis machining produces exceptional surface finishes. The continuous optimal tool orientation minimizes cusp marks and scalloping effects that are common with 3-axis machining of complex surfaces. This capability is particularly valuable for components requiring aerodynamic surfaces or fluid dynamic properties where surface imperfections can significantly impact performance.

Complex Geometry Capability: 5-axis machining enables the production of geometries that would be impossible with traditional machining methods. This includes undercuts, deep cavities, compound curves, and features on multiple part faces without repositioning. The technology particularly excels at manufacturing impellers, turbine blades, mold cores, and prototype components with organic, complex shapes.

Reduced Tooling Requirements: Despite the higher initial investment in 5-axis equipment, the technology often reduces overall tooling costs. Shorter, more rigid tools can be used since the machine can orient the workpiece to maintain optimal tool engagement. This reduces tool deflection, improves surface finish, and extends tool life by 25-40% compared to 3-axis machining of complex parts.

Improved Material Removal Rates: The ability to maintain optimal tool orientation and engagement throughout complex machining operations allows for significantly higher material removal rates (MRR). By tilting the workpiece to present the optimal cutting angle, 5-axis machines can maintain higher feed rates while reducing tool wear and minimizing vibration during heavy cutting operations.

Table: Comparison of Machining Technologies for Complex Parts

| Technology | Positioning Accuracy | Surface Finish (Ra) | Minimum Feature Size | Setup Requirements | Complex Geometry Capability |

|---|---|---|---|---|---|

| 3-Axis CNC | ±0.025mm | 0.8-3.2μm | 0.5mm | Multiple setups | Limited to accessible features |

| 3+2 Axis | ±0.015mm | 0.4-1.6μm | 0.25mm | Reduced setups | Moderate complexity |

| 5-Axis Simultaneous | ±0.005mm | 0.1-0.4μm | 0.1mm | Single setup | High complexity |

| 5-Axis with Advanced Control | ±0.002mm | 0.05-0.2μm | 0.05mm | Single setup | Extreme complexity |

3 5-Axis Machine Configurations and Capabilities

5-axis CNC machining centers come in various configurations, each offering specific advantages for different types of complex parts:

Table-Table Configuration: This design features a tilting-rotary table that handles both rotational axes while the spindle moves along the three linear axes. Machines with this configuration, such as the Huron UMILL 5, typically offer work envelopes up to 500×560×450mm (X,Y,Z) with table load capacities reaching 450kg. The fixed portal structure provides exceptional stability during heavy cutting operations, making this configuration ideal for medium-sized complex components.

Spindle-Head Configuration: This design incorporates the rotational axes in the spindle head, allowing it to tilt and rotate while the table moves along the linear axes. This configuration excels at machining very large components since the workpiece doesn’t require tilting. The YCM TCV3000A-5AX exemplifies this approach with its large work envelope and high-power spindle capable of heavy machining operations.

Gantry Configuration: Gantry-style 5-axis machines feature a bridge-like structure that provides exceptional stability and accuracy for very large components. These machines often have work envelopes measuring several meters in each dimension while maintaining precision tolerances. They’re particularly valuable for aerospace components, large mold bases, and automotive tooling.

Hybrid Configuration: Advanced 5-axis machines may combine elements of multiple configurations to optimize for specific applications. These hybrid systems often incorporate linear motor technology for rapid positioning, thermally stable structures to maintain accuracy during long production runs, and advanced control systems that compensate for tool deflection and thermal expansion in real-time.

Modern 5-axis machining centers incorporate numerous advanced features that enhance their capability for complex parts manufacturing:

High-Speed Spindles: Advanced 5-axis machines feature spindles capable of 10,000-30,000 RPM with power ratings from 15-80kW. These spindles often incorporate ceramic bearings and direct-drive technology for minimal vibration and maximum precision at high speeds.

Advanced Control Systems: Modern 5-axis controls include features such as kinematic transformation that automatically calculates optimal tool paths, collision avoidance that prevents tool, holder, or spindle interference with the workpiece or fixtures, and adaptive feed control that maintains optimal cutting conditions throughout complex operations.

Precision Feedback Systems: High-resolution encoders on all axes, including the rotational axes, provide positioning accuracy to within arc-seconds for rotational movement and microns for linear movement. Laser calibration systems regularly verify machine geometry to maintain accuracy over time.

Automation Integration: Most modern 5-axis machining centers are designed for seamless integration with automation systems including robotic part loading, pallet changers, and integrated measurement systems that enable lights-out manufacturing of complex components.

4 Applications Across Industries

5-axis CNC machining has transformed manufacturing across numerous industries that require complex, high-precision components:

Aerospace Components

The aerospace industry represents one of the most demanding applications for 5-axis machining. Complex components such as engine mounts, structural brackets, landing gear elements, and turbine blades require the capabilities of 5-axis technology. These components often feature complex curvatures, thin walls, and precisely controlled aerodynamic surfaces that must withstand extreme environmental conditions and loading scenarios.

Aerospace manufacturers have achieved remarkable results with 5-axis technology. One aerospace manufacturer reported 45% reduction in processing time for turbine blades while achieving surface finishes of Ra 0.4μm and maintaining dimensional accuracy within 0.02mm on critical features. The ability to machine these complex components from solid billets of high-temperature alloys provides significant advantages over traditional manufacturing approaches.

Medical Devices and Implants

The medical industry utilizes 5-axis machining for complex surgical instruments, implantable devices, and diagnostic equipment. Components such as orthopedic implants, surgical handpieces, prosthetic devices, and minimally invasive surgical instruments require the precision and complexity capabilities of 5-axis technology.

Medical device manufacturers report significant improvements through 5-axis implementation. One manufacturer achieved 70% improvement in machining efficiency for complex porous structures on titanium bone plates while increasing first-pass yield from 82% to 98%. The ability to maintain sterile surface finishes while achieving complex biological-inspired geometries has enabled significant advances in patient-specific medical devices.

Automotive and Motorsports

High-performance automotive and motorsport applications extensively use 5-axis machining for components where weight reduction, structural integrity, and complex geometries are critical. Applications include engine blocks, cylinder heads, transmission cases, suspension components, and aerodynamic elements.

The automotive industry has realized substantial benefits from 5-axis machining. One electric vehicle manufacturer reported 18% weight reduction in battery enclosure frames while improving dynamic balance by 40%. The ability to consolidate multiple components into single complex parts has significantly simplified assembly processes while improving overall performance and reliability.

Energy Sector Components

The energy industry, including traditional power generation, renewable energy, and oil and gas applications, utilizes 5-axis machining for complex components. These include turbine blades, compressor rotors, heat exchanger elements, and drilling equipment components that must operate reliably in extreme environments.

Energy sector manufacturers have achieved impressive results with 5-axis technology. One manufacturer reported 20% reduction in total processing time for complex turbine components while improving dimensional accuracy and surface finish specifications. The ability to machine these components from high-strength, corrosion-resistant materials provides significant advantages for energy applications.

*Table: 5-Axis Machining Applications by Industry*

| Industry | Typical Components | Material Challenges | Precision Requirements | Surface Finish Needs |

|---|---|---|---|---|

| Aerospace | Turbine blades, structural components | High-temperature alloys, titanium | ±0.025mm | Ra 0.2-0.4μm |

| Medical | Implants, surgical instruments | Titanium, stainless steel, ceramics | ±0.012mm | Ra 0.1-0.2μm |

| Automotive | Engine components, transmission parts | Aluminum alloys, cast iron | ±0.015mm | Ra 0.4-0.8μm |

| Energy | Turbine components, compressor parts | Nickel alloys, stainless steel | ±0.018mm | Ra 0.3-0.6μm |

| Mold & Die | Injection molds, die casting dies | Tool steels, carbide | ±0.008mm | Ra 0.05-0.1μm |

5 Materials for Complex 5-Axis Machined Parts

5-axis CNC machining accommodates an extensive range of materials, each presenting unique machining characteristics and challenges:

Aerospace Alloys

Aerospace applications frequently utilize high-performance materials that challenge even advanced 5-axis machining capabilities. Titanium alloys (Ti-6Al-4V) offer exceptional strength-to-weight ratio and corrosion resistance but present machining challenges due to their low thermal conductivity and tendency to work-harden. Nickel-based superalloys (Inconel 718, Waspaloy) maintain strength at elevated temperatures but are exceptionally abrasive and require specialized tooling and techniques. Aluminum alloys (7075, 2024) provide good machinability and strength while allowing for high material removal rates.

Medical Materials

Medical applications require materials with excellent biocompatibility and specific mechanical properties. Medical-grade titanium (Ti-6Al-4V ELI) offers excellent biocompatibility and mechanical properties for implantable devices. Stainless steels (316L, 17-4PH) provide good corrosion resistance and mechanical properties for surgical instruments. Cobalt-chromium alloys offer exceptional wear resistance for joint replacement surfaces. PEEK and other engineering plastics provide radiolucency and bone-like stiffness for trauma and spinal implants.

Automotive Materials

The automotive industry utilizes a wide range of materials optimized for specific applications. Aluminum alloys (A380, 6061, 7075) provide good strength-to-weight ratio for engine and transmission components. Cast iron offers excellent damping properties and wear resistance for engine blocks and brake components. Magnesium alloys provide extreme light weighting for components where weight reduction is critical. Composite materials offer exceptional strength-to-weight ratio for structural components.

Tool and Mold Steels

Mold and die applications require materials that can withstand repeated cycling while maintaining precision. P20 steel offers good machinability and polishability for injection molds. H13 tool steel provides excellent thermal fatigue resistance for die casting applications. S7 tool steel offers good impact resistance for punch and die applications. Stavax and other stainless mold steels provide excellent corrosion resistance and polishability for optical-quality molds.

6 Technical Considerations for 5-Axis Machining

Successful implementation of 5-axis machining for complex parts requires careful attention to numerous technical considerations:

Machine Calibration and Maintenance: Maintaining precision in 5-axis machining requires regular calibration and preventive maintenance. Volumetric accuracy verification using laser trackers or similar systems ensures all axes move precisely relative to each other. Rotary axis calibration is particularly critical for maintaining accuracy throughout the rotational range. Regular ballbar testing verifies circular interpolation accuracy while spindle analysis ensures optimal cutting performance.

Tooling Selection and Management: 5-axis machining places unique demands on cutting tools. Shortest possible tool lengths minimize deflection and vibration while specialized tool geometries optimize performance for specific materials and operations. Tool holding systems with minimal runout (less than 0.003mm) ensure precision machining, while balanced toolholders are essential for high-speed operations. Tool management systems track tool life and performance to maintain consistent quality throughout production runs.

Programming and Simulation: Advanced CAM software with dedicated 5-axis programming capabilities is essential for complex parts. Multi-axis toolpath strategies optimize tool orientation and engagement throughout complex operations. Full machine simulation verifies programs without requiring machine time while identifying potential collisions before they occur. Post-processor development tailors machine code to specific machine tool characteristics and capabilities.

Workholding Solutions: Specialized workholding is often required for complex 5-axis machining. Custom fixtures position parts optimally for machining while providing secure clamping without interference. Modular workholding systems provide flexibility for different part geometries while maintaining precision location. Pneumatic and hydraulic clamping systems provide consistent clamping force without requiring operator intervention. Zero-point mounting systems facilitate rapid changeover between different fixtures and part types.

Process Monitoring and Control: Advanced process monitoring ensures consistent quality throughout 5-axis machining operations. Tool condition monitoring detects wear and breakage before they affect part quality. Vibration analysis identifies unstable cutting conditions before they damage tools or workpieces. Adaptive control systems adjust feed rates and spindle speeds based on actual cutting conditions to maintain optimal performance throughout the operation.

7 Case Studies: 5-Axis Machining Success Stories

Case Study 1: Aerospace Turbine Component Manufacturing

An aerospace manufacturer required complex turbine blades with precise aerodynamic profiles and internal cooling channels for a new jet engine design. The blades measured 380mm long with wall thicknesses as thin as 0.5mm in critical areas. Traditional manufacturing methods would require multiple setups and extensive hand work, resulting in inconsistent quality and long lead times.

Solution: The manufacturer implemented a 5-axis machining strategy using a DMG Mori DMU 200 P machining center with advanced thermally stable construction and high-precision rotary axes. The machining process utilized specialized tapered ball-nose end mills for the complex contoured surfaces and micro-tools for the internal cooling channels. The CAM programming incorporated streamline machining strategies that followed the natural curvature of the blade surfaces, maintaining optimal tool orientation throughout the operation.

Results: The 5-axis implementation reduced overall processing time by 45% while improving surface finish to Ra 0.4μm. Dimensional accuracy on critical aerodynamic surfaces improved to within 0.02mm, significantly enhancing turbine efficiency. The single-setup approach eliminated accumulated errors from multiple repositioning operations, improving consistency between components and reducing rejection rates by 60%.

Case Study 2: Medical Implant Manufacturing

A medical device company needed to produce patient-specific cranial implants with complex geometries matching individual patient anatomy. The implants required precise fit to existing bone structures, complex porous surfaces to encourage bone integration, and exceptional surface finish to minimize tissue irritation. Traditional manufacturing methods couldn’t achieve the required combination of complexity, precision, and surface finish.

Solution: The company implemented a hybrid manufacturing approach using 5-axis machining combined with additive manufacturing. The implant substrates were produced using laser powder bed fusion to create the complex porous structures, then finished using 5-axis machining to achieve critical sealing surfaces and precise edge features. The machining operations utilized specialized micro-grain carbide tools and high-speed machining strategies to achieve the required surface finishes on the difficult-to-machine titanium alloy.

Results: The hybrid approach reduced overall manufacturing time by 70% compared to previous methods while improving first-pass yield from 82% to 98%. The implants achieved excellent clinical outcomes with reduced surgery time and improved patient recovery. The ability to maintain sterile surface finishes while achieving complex biological-inspired geometries enabled significant advances in patient-specific medical devices.

Case Study 3: Automotive Transmission Component

An automotive manufacturer needed to produce a new integrated transmission housing for an electric vehicle that combined multiple functions into a single complex component. The housing required precise bearing bores (IT6 tolerance), complex internal passages for lubrication and cooling, and structural integrity to withstand powertrain loads. Traditional manufacturing would require multiple components assembled together, increasing weight and potential failure points.

Solution: The manufacturer utilized a 5-axis machining center with large work envelope and high-power spindle capable of heavy roughing operations followed by precision finishing. The machining process incorporated specialized boring tools with continuous diameter adjustment capability for the precision bearing bores and long-reach tools for the internal passages. The programming utilized adaptive roughing strategies to efficiently remove large volumes of aluminum followed by precision finishing operations that maintained tolerances despite the size of the component.

Results: The integrated design reduced overall weight by 18% while improving structural stiffness by 30%. The single-component approach eliminated 12 separate parts from the previous design, simplifying assembly and improving reliability. The 5-axis machining approach maintained bearing bore tolerances within 0.008mm despite the size of the component, ensuring optimal powertrain performance.

8 Future Trends in 5-Axis Machining

The field of 5-axis machining continues to evolve with several emerging trends shaping the future of complex parts manufacturing:

Additive and Subtractive Hybrid Manufacturing: The integration of additive manufacturing with 5-axis machining creates new possibilities for complex components. This approach allows for building near-net-shape parts with complex internal features using additive processes, then precision machining critical surfaces using 5-axis capabilities. This hybrid approach is particularly valuable for conformal cooling channels in mold tools, lightweight structural components with internal lattice structures, and repair of high-value components.

IoT and Industry 4.0 Integration: Modern 5-axis machining centers are increasingly connected within smart manufacturing environments. Real-time monitoring of machine conditions, predictive maintenance based on actual usage patterns, and adaptive control systems that optimize processes based on sensor data are becoming standard features. This connectivity enables lights-out manufacturing of complex components with minimal human intervention.

Advanced Materials Capability: 5-axis machining is expanding to handle increasingly challenging materials. Ceramic matrix composites, metal matrix composites, and advanced engineering plastics are being machined with 5-axis technology to create components for extreme environments. These materials often require specialized tooling, unique cutting strategies, and advanced cooling techniques to achieve required precision and surface finish.

Sustainability Improvements: The 5-axis machining industry is focusing increasingly on sustainability through reduced energy consumption, longer tool life, and improved material utilization. High-efficiency spindles, regenerative drive systems, and optimized cutting strategies reduce energy consumption while advanced tool coatings and condition monitoring extend tool life. The single-setup capability of 5-axis machining significantly reduces material waste compared to multiple-setup approaches.

Simplified Programming Interfaces: While 5-axis machining capabilities advance, programming interfaces are becoming more intuitive and accessible. Conversational programming systems allow skilled machinists to create complex 5-axis toolpaths without extensive CAM software knowledge. Augmented reality interfaces provide intuitive visualization of complex toolpaths and machine movements, reducing programming time and minimizing errors.

9 Conclusion: Leveraging 5-Axis Machining for Competitive Advantage

5-axis CNC machining has evolved from a specialized manufacturing technology to a mainstream solution for producing complex components across numerous industries. The ability to machine intricate geometries with exceptional precision in a single setup provides significant advantages in terms of quality, efficiency, and total manufacturing cost. As components become increasingly complex and performance requirements more stringent, 5-axis machining will continue to grow in importance.

The successful implementation of 5-axis machining requires careful consideration of multiple factors including machine selection, tooling strategies, programming approaches, and workholding solutions. Companies that master these elements can achieve significant competitive advantages through reduced time to market, improved product performance, and lower total manufacturing costs.

At JL YPT, we have invested in advanced 5-axis machining technology and developed the expertise necessary to manufacture even the most complex components to the highest quality standards. Our facilities include precision 5-axis machining centers with capabilities ranging from micro-machining of medical components to large-format machining of aerospace structures. Our engineering team has extensive experience with advanced materials, complex geometries, and stringent quality requirements across multiple industries.

Ready to discuss your complex machining project? Contact JL YPT today to leverage our 5-axis machining expertise for your most challenging component requirements.