Aerospace-Grade Titanium Coating Services in CNC Machining: Ensuring Superior Performance

Introduction

In the aerospace industry, components must withstand extreme conditions, including high temperatures, corrosive environments, and rigorous mechanical stress. Aerospace-grade titanium coating services play a pivotal role in enhancing the durability, performance, and reliability of these components. As a leading CNC machining service provider in China, Jlypt specializes in delivering aerospace-grade titanium coating solutions tailored to meet the unique requirements of aerospace applications.

The Importance of Aerospace-Grade Titanium Coatings

Titanium is renowned for its exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand high temperatures. Aerospace-grade titanium coatings further enhance these properties, providing additional layers of protection and performance. These coatings are essential for ensuring that aerospace components function optimally in the harshest environments.

Jlypt’s Aerospace-Grade Titanium Coating Services in CNC Machining

At Jlypt, we integrate aerospace-grade titanium coating services seamlessly into our CNC machining process. Our state-of-the-art facilities and skilled technicians enable us to apply high-quality titanium coatings that meet or exceed aerospace industry standards. Our services include:

- Physical Vapor Deposition (PVD): Applying a thin, uniform layer of titanium to the component surface for enhanced hardness and wear resistance.

- Chemical Vapor Deposition (CVD): Forming a dense, adherent titanium coating through chemical reactions at high temperatures.

- Titanium Plasma Spray: Applying a thick, porous titanium coating using plasma torches for thermal insulation and corrosion resistance.

- Titanium Anodizing: Creating a protective oxide layer on titanium surfaces for enhanced corrosion resistance and aesthetic appeal.

Detailed Table of Aerospace-Grade Titanium Coating Services

Below is a detailed table showcasing Jlypt’s aerospace-grade titanium coating services, their applications, typical characteristics, and example images:

| Coating Type | Application | Characteristics | Example Image |

|---|---|---|---|

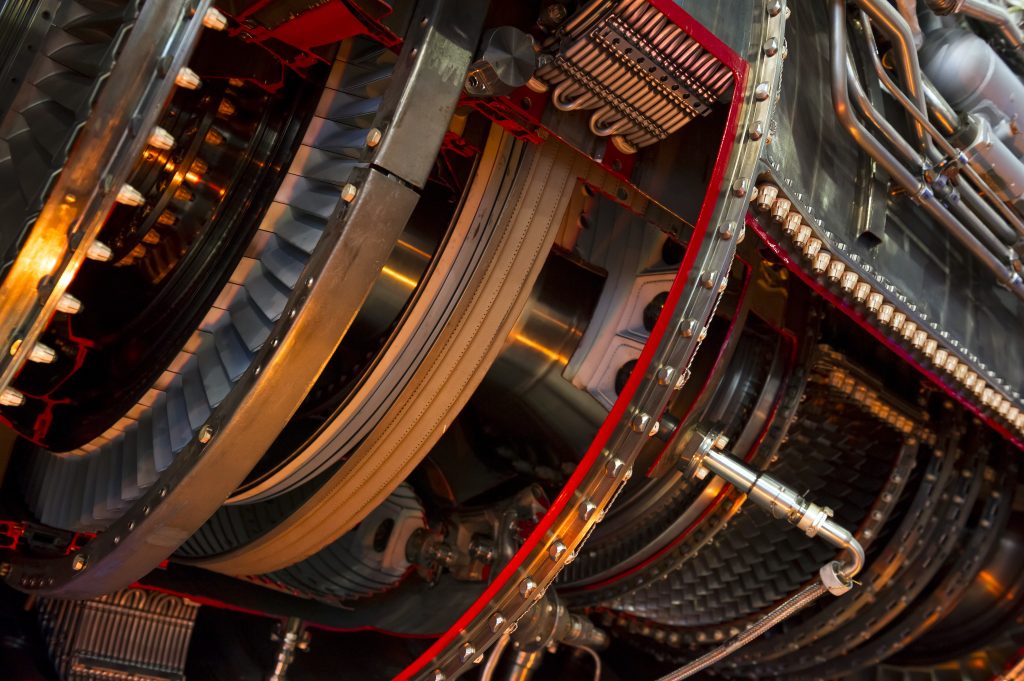

| Physical Vapor Deposition (PVD) | Turbine blades, engine components, aerospace fasteners | Thin, uniform layer; enhanced hardness and wear resistance |  |

| Chemical Vapor Deposition (CVD) | Combustion chambers, nozzles, and high-temperature components | Dense, adherent coating; high temperature resistance and corrosion protection |  |

| Titanium Plasma Spray | Thermal insulation barriers, corrosion-resistant surfaces | Thick, porous coating; excellent thermal insulation and corrosion resistance |  |

| Titanium Anodizing | Aerospace exterior panels, decorative components, and protective surfaces | Protective oxide layer; enhanced corrosion resistance and aesthetic appeal |  |

Case Studies

Case Study 1: PVD Coating for Turbine Blades

A leading aerospace engine manufacturer approached Jlypt for PVD coating services for their turbine blades. The blades required enhanced hardness and wear resistance to withstand the extreme temperatures and mechanical stress encountered during flight. Jlypt’s PVD coating process successfully met these requirements, ensuring the blades performed optimally and reducing maintenance costs for the manufacturer.

Case Study 2: CVD Coating for Combustion Chambers

An aerospace company specializing in high-performance jet engines sought Jlypt’s expertise for CVD coating their combustion chambers. The chambers needed a dense, adherent coating to withstand the high temperatures and corrosive environments encountered during operation. Jlypt’s CVD coating process provided the required protection, enabling the combustion chambers to function reliably and efficiently.

Case Study 3: Titanium Plasma Spray for Thermal Insulation Barriers

A manufacturer of aerospace thermal insulation barriers approached Jlypt for titanium plasma spray coating services. The barriers required a thick, porous coating to provide excellent thermal insulation and corrosion resistance. Jlypt’s titanium plasma spray process delivered the desired coating, ensuring the barriers met the manufacturer’s stringent performance requirements.

Conclusion

Aerospace-grade titanium coating services play a crucial role in ensuring the superior performance and reliability of aerospace components. At Jlypt, we offer a wide range of tailored titanium coating solutions designed specifically for CNC machining applications. Our expertise, combined with state-of-the-art equipment and skilled technicians, ensures that every component leaves our facility with a coating that meets or exceeds aerospace industry standards.

For more information or to request a quote, please visit our website at https://www.jlypt.com/anodizing-near-me-surface-finishing-services/ or contact us at [email protected]. We look forward to partnering with you on your next aerospace component project!