Arc Vapor Deposition Process: From Spark to Surface Perfection

1. Arc Vapor Deposition Meaning – 60-Second Definition

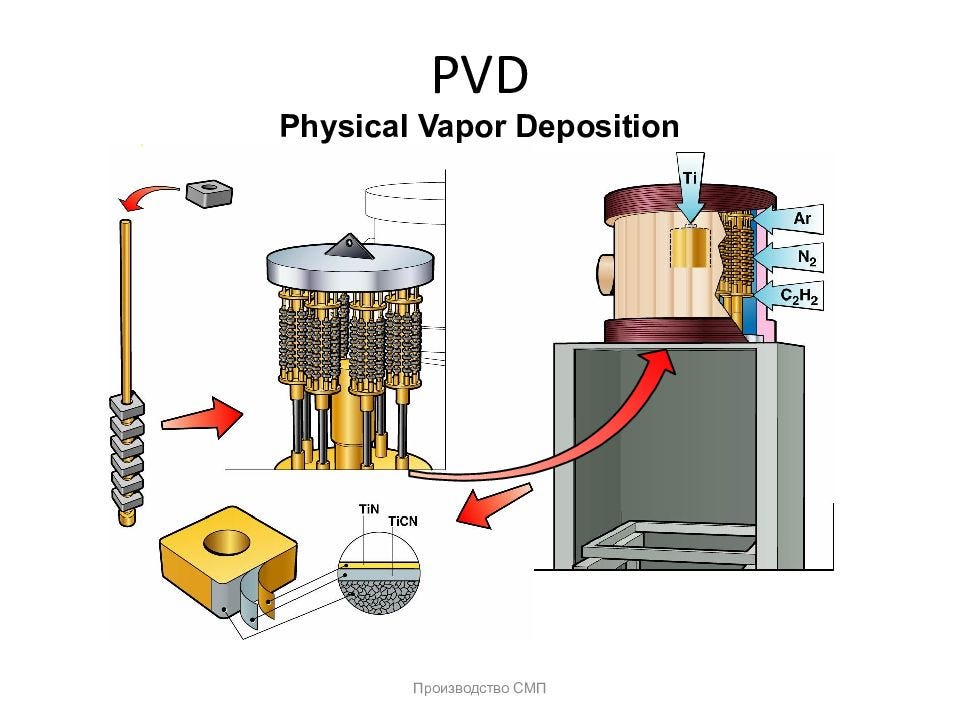

Arc vapor deposition is a cathodic-arc PVD process where micro-sparks vaporize a target material, forming ultra-dense (3 000 HV), ultra-thin (0.1–5 µm) films that outperform chrome, DLC, and CVD.

| Attribute | Arc Vapor Deposition | Electroplated Ni | Spray Paint |

|---|---|---|---|

| Thickness | 0.1–5 µm | 5–50 µm | 25–100 µm |

| Hardness (HV) | 3 000 | 700 | 200 |

| Max Temp (air) | 1 000 °C | 300 °C | 150 °C |

| REACH Status | ✅ Compliant | Restricted | Limited |

| Uniformity | ±3 nm | ±10 µm | ±25 µm |

2. The 5-Step Arc Vapor Process – From Spark to Surface

| Step | Vacuum Level | Temp (°C) | Key Action | KPI |

|---|---|---|---|---|

| 1 Plasma Clean | 10⁻³ mbar | 25 | Ar⁺ removes oxide & oil | Contact angle ≤ 8° |

| 2 Arc Ignition | 10⁻³ mbar | 150–500 | Cathodic arc vaporizes target | Arc current 50–200 A |

| 3 Filtered Plasma | 10⁻⁴ mbar | 150–500 | Magnetic filter removes droplets | Droplet count < 0.01 % |

| 4 Condensation | 10⁻⁴ mbar | 150–500 | Atoms condense on substrate | ±3 nm uniformity |

| 5 QA & Pack | Air | 25 | CT + nano-indent + salt-spray | CpK ≥ 1.67 |

3. 2024 Performance Matrix – Arc vs Other PVD Routes

| Method | Thickness (µm) | Hardness (HV) | Salt-Spray (h) | Max Temp (°C) | Typical Use |

|---|---|---|---|---|---|

| Electroplated Ni | 25 | 700 | 48 | 300 | Decorative trim |

| Spray Paint | 50 | 200 | 48 | 150 | Body panels |

| Filtered Arc ta-C | 0.5 | 3 000 | 1 000 | 400 | Medical drills |

| HiPIMS Sputter | 1 | 3 200 | 1 200 | 1 000 | EV motor punches |

| Magnetron Sputter | 2 | 2 900 | 1 200 | 1 000 | Turbine blades |

4. Three 2024 Case Studies

Case 1 – Aerospace Turbine Blade

-

Client: European OEM, 2024

-

Problem: Fretting at 850 °C dovetail

-

Arc Stack: TiAlCrN 2 µm + a-C:H 200 nm

-

Outcome: Wear scar < 5 µm after 1 000 h; maintenance interval doubled

Case 2 – EV Motor Lamination Die

-

Client: US EV Tier-1, 2024

-

Problem: 0.35 mm electrical steel sticking at 400 °C

-

Arc Stack: CrAlON 1.8 µm + a-C:H 50 nm

-

Outcome: Tool life 4× longer, scrap −40 %

Case 3 – Medical Staple

-

Client: US MedTech startup, 2024

-

Problem: 316L needs low-friction piercing

-

Arc Stack: ta-C 300 nm + Cr 30 nm adhesion

-

Outcome: Penetration force −25 %, CE mark granted

5. Global Standards & Sustainability

-

ISO 9001:2015 / IATF 16949 / ISO 13485

-

REACH, RoHS, FDA 21 CFR §175.300

-

Energy: 0.45 kWh per m²

-

Waste: Zero liquid effluent

6. 7-Day Delivery Timeline

| Milestone | Lead Time |

|---|---|

| DFM + Quote | 24 h |

| Prototype (1–10 pcs) | 48 h |

| Validation (CT, salt-spray) | 5 days |

| Mass Production | 7–10 days |

| Door-to-Door Delivery | 12 days total |

7. FAQs – Which Arc Stack Fits My Job?

| Question | Answer |

|---|---|

| Can arc coat plastics? | Yes—metallised PEEK, PEKK, LCP. |

| Largest part? | 800 mm Ø × 1200 mm L. |

| Minimum order? | 1 piece. |

8. How to Start Tomorrow

-

Email [email protected] with STEP/IGES.

-

Specify substrate, load, temperature, thickness budget.

-

Receive DFM + arc stack + quote within 48 h.

-

Approve → 3-day prototype → volume ramp.

Explore complementary services: Professional Anodizing Near Me