What is the Best Surface Finish for Aerospace Titanium Parts in CNC Machining?

Introduction

In the aerospace industry, titanium parts are known for their strength, lightweight properties, and corrosion resistance. However, achieving the optimal surface finish for these parts is crucial to ensuring their functionality, durability, and aesthetic appeal. As a leading CNC machining service provider in China, Jlypt specializes in delivering precision-machined titanium parts with the best surface finishes tailored to aerospace applications.

Understanding Surface Finish in Aerospace Titanium Parts

The surface finish of aerospace titanium parts refers to the texture, smoothness, and overall appearance of the machined surface. It is a critical factor that can affect the part’s performance, including its ability to withstand extreme temperatures, pressures, and corrosive environments.

Factors to Consider When Choosing the Best Surface Finish

When determining the best surface finish for aerospace titanium parts, several factors must be considered:

- Functional Requirements: The surface finish must meet the functional requirements of the part, such as friction reduction, wear resistance, and sealing properties.

- Durability: The finish must be durable enough to withstand the rigors of aerospace applications, including exposure to high temperatures, pressures, and corrosive agents.

- Aesthetic Appeal: The surface finish should also enhance the part’s aesthetic appeal, contributing to the overall quality and perception of the aerospace product.

- Manufacturing Constraints: The chosen surface finish must be achievable within the constraints of the manufacturing process, including equipment capabilities, material properties, and cost considerations.

Jlypt’s Guide to the Best Surface Finishes for Aerospace Titanium Parts

Below is a detailed guide to the best surface finishes for aerospace titanium parts, along with a table showcasing common finishes, their characteristics, and typical applications.

| Surface Finish | Description | Ra (μm) | CNC Process | Applications |

|---|---|---|---|---|

| Mirror-like Finish | Smooth, defect-free surface | <0.1 | Diamond turning, Superfinishing | High-precision aerospace components |

| Satin Finish | Uniform, matte appearance | 0.2 – 0.8 | Polishing, Vibratory finishing | Aerospace interior components |

| Brushed Finish | Directional texture with a brushed appearance | 0.4 – 1.6 | Brushing, Grinding | Aerospace exterior components |

| Shot Peened Finish | Compressed surface with improved fatigue life | Varies | Shot peening | Aerospace structural components |

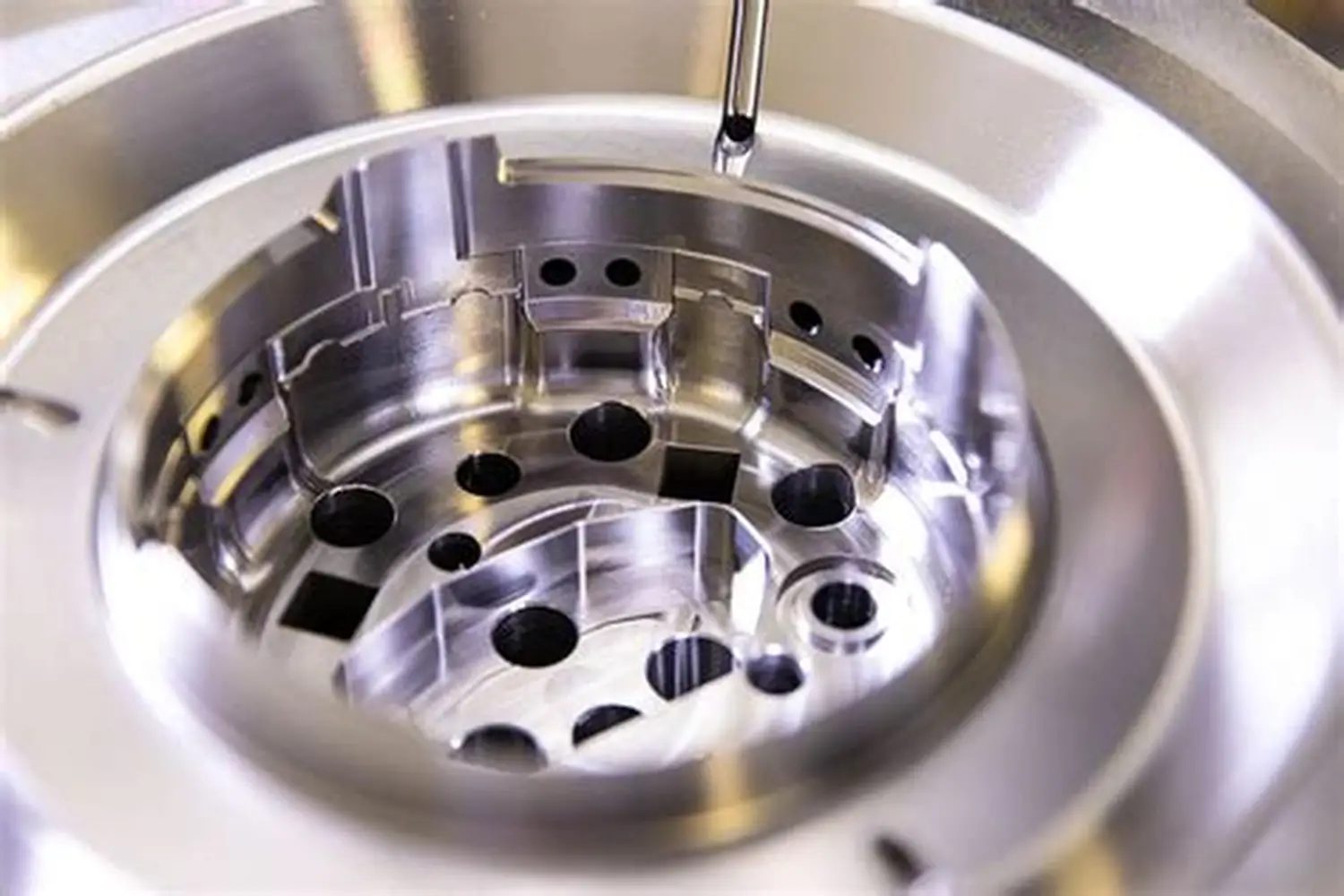

Mirror-like Finish

A mirror-like finish is characterized by an ultra-smooth, defect-free surface with an Ra value of less than 0.1μm. This finish is achieved through processes such as diamond turning and superfinishing. It is ideal for high-precision aerospace components that require minimal friction, excellent sealing properties, and a high-quality appearance.

Case Study 1: Aerospace Seal Rings

For aerospace seal rings, Jlypt employed a mirror-like finish to ensure a perfect seal and minimize friction. The Ra value was reduced to below 0.1μm, contributing to the part’s reliability and performance in extreme conditions.

Satin Finish

A satin finish provides a uniform, matte appearance with an Ra value between 0.2 and 0.8μm. It is achieved through polishing and vibratory finishing processes. This finish is ideal for aerospace interior components that require a clean, aesthetically pleasing appearance while maintaining durability.

Case Study 2: Aerospace Cabin Interior Panels

Jlypt applied a satin finish to aerospace cabin interior panels, enhancing their aesthetic appeal and contributing to a high-quality passenger experience. The finish also provided the necessary durability to withstand frequent use and cleaning.

Brushed Finish

A brushed finish creates a directional texture with a brushed appearance, typically with an Ra value between 0.4 and 1.6μm. It is achieved through brushing and grinding processes. This finish is suitable for aerospace exterior components that require a durable, scratch-resistant surface with a visually appealing texture.

Case Study 3: Aerospace Exterior Panels

For aerospace exterior panels, Jlypt utilized a brushed finish to provide a robust surface that could withstand the rigors of flight while maintaining a sleek, modern appearance. The finish also helped to camouflage minor scratches and blemishes, extending the part’s visual longevity.

Shot Peened Finish

A shot peened finish involves compressing the surface of the titanium part to improve its fatigue life. This finish is characterized by a roughened texture and is ideal for aerospace structural components that are subjected to high cyclic loads.

Case Study 4: Aerospace Landing Gear Components

Jlypt applied a shot peened finish to aerospace landing gear components, enhancing their fatigue resistance and extending their service life. The roughened texture also provided improved grip and wear resistance, contributing to the part’s overall performance.

Conclusion

Achieving the best surface finish for aerospace titanium parts requires a deep understanding of the material’s properties, the functional requirements of the part, and the capabilities of the manufacturing process. At Jlypt, we specialize in delivering precision-machined titanium parts with optimal surface finishes tailored to aerospace applications. Our state-of-the-art equipment, highly skilled team, and commitment to quality ensure that every part meets or exceeds your expectations.

For more information or to request a quote, please visit our website at https://www.jlypt.com/anodizing-near-me-surface-finishing-services/ or contact us at [email protected].