7 Advanced Manufacturing Techniques for High-Performance Integrated Actuator Robot Systems

Introduction: The Evolution of Compact Robotic Actuation

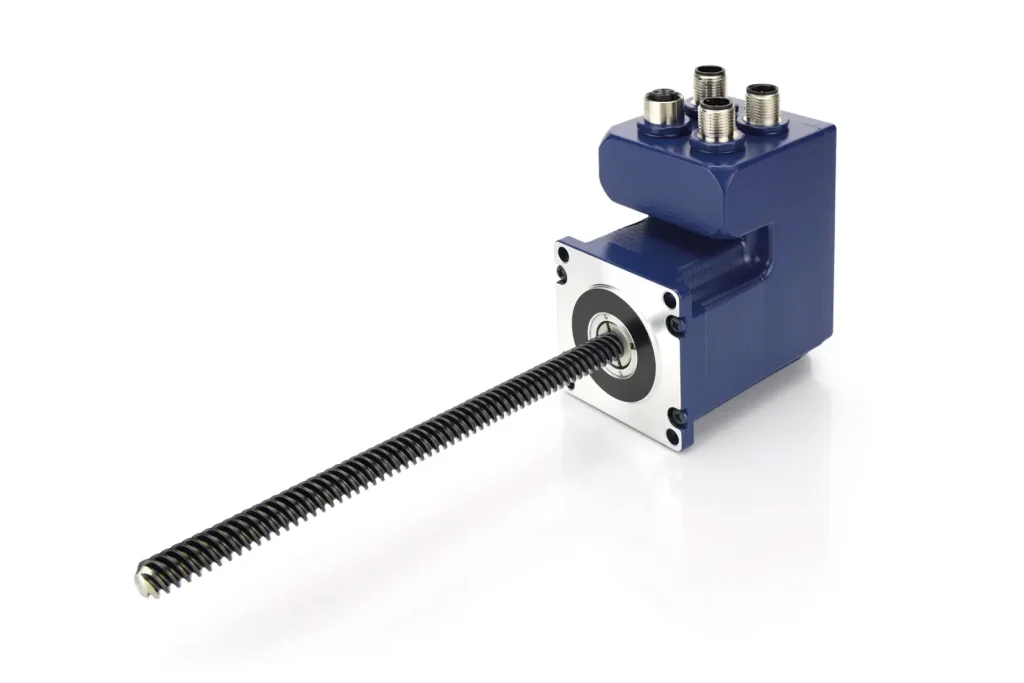

The emergence of integrated actuator robot technology represents a significant milestone in the evolution of industrial automation, combining multiple motion control components into single, compact units that deliver exceptional performance in minimal space. These sophisticated systems integrate motors, drives, sensors, and control electronics into unified packages that redefine the possibilities for robotic design and implementation. The integrated actuator robot approach eliminates traditional component interfaces and interconnections, resulting in improved system reliability, reduced installation complexity, and enhanced overall performance. This technological advancement has become particularly crucial as industries demand more compact, efficient, and intelligent robotic solutions for space-constrained applications.

As precision engineering specialists at JLYPT, we have developed comprehensive expertise in manufacturing critical components for integrated actuator robot systems. This detailed technical analysis explores seven essential manufacturing techniques that enable the production of high-performance integrated actuator systems, while examining the engineering principles that ensure optimal performance across diverse industrial applications and operating conditions.

1. System Architecture and Integration Principles

1.1 Unified Design Methodology

The integrated actuator robot represents a paradigm shift from traditional modular approaches, incorporating multiple subsystems into cohesive, optimized packages. Understanding this integrated architecture is fundamental to appreciating the manufacturing requirements and performance advantages.

Key Integrated System Components:

-

Motor Assembly: High-torque density motor with optimized electromagnetic design

-

Drive Electronics: Integrated power electronics and control circuitry

-

Feedback Systems: Multi-sensor integration for position, torque, and temperature monitoring

-

Thermal Management: Advanced cooling systems integrated within the housing structure

-

Communication Interfaces: Built-in network connectivity and protocol support

Performance Advantages of Integrated Systems:

| System Aspect | Traditional Actuator | Integrated Actuator Robot | Improvement Factor |

|---|---|---|---|

| Installation Time | 4-8 hours | 1-2 hours | 4x faster |

| System Footprint | 100% reference | 40-60% | 40-60% reduction |

| Component Interfaces | 15-25 connections | 3-5 connections | 5x reduction |

| System Reliability | 20,000 hours MTBF | 50,000+ hours MTBF | 2.5x improvement |

| Control Bandwidth | 100-500 Hz | 1-2 kHz | 3-5x increase |

1.2 Performance Classification and Applications

Integrated Actuator Robot Performance Categories:

| System Class | Torque Range (Nm) | Speed Range (RPM) | Power Range (W) | Typical Applications |

|---|---|---|---|---|

| Micro Integrated | 0.1-5 | 100-10,000 | 50-500 | Small collaborative robots, medical devices |

| Standard Industrial | 5-200 | 50-6,000 | 500-2,000 | Industrial automation, assembly robots |

| High Performance | 200-1,000 | 50-4,000 | 2,000-10,000 | CNC machinery, material handling |

| High Torque | 1,000-5,000 | 10-2,000 | 10,000-25,000 | Heavy automation, construction equipment |

| Ultra-Precision | 1-50 | 100-8,000 | 100-1,000 | Semiconductor, aerospace applications |

2. Advanced Material Selection and Engineering

2.1 Comprehensive Material Strategy

The performance of integrated actuator robot systems depends on advanced material selection where electromagnetic, thermal, and structural properties are carefully balanced for optimal system performance.

Material Selection Matrix for Integrated Systems:

| Material Specification | Component Application | Key Properties | Thermal Characteristics | Weight Savings |

|---|---|---|---|---|

| Aluminum 6061-T6 | Housing, structural components | Good strength-to-weight | Thermal conductivity 167 W/m·K | 60% vs steel |

| Aluminum 7075-T6 | High-strength sections | High strength | Thermal conductivity 130 W/m·K | 55% vs steel |

| Copper C10100 | Thermal paths, windings | High conductivity | Thermal conductivity 391 W/m·K | – |

| Stainless 17-4PH | Shafts, fasteners | Corrosion resistance | Thermal conductivity 18 W/m·K | 15% vs steel |

| Electrical Steel M19 | Magnetic circuits | Low core loss | Curie temperature 740°C | – |

| Thermal Composites | Heat sinks | High conductivity | 50-400 W/m·K | 40% vs copper |

2.2 Specialized Material Processing

Advanced Thermal Management Materials:

-

Vapor Chamber Systems: Two-phase cooling with effective thermal conductivity >5,000 W/m·K

-

Thermal Interface Materials: Advanced composites with conductivity 3-15 W/m·K

-

Phase Change Materials: Latent heat storage capacity 100-200 kJ/kg

-

Carbon Composites: Directional thermal conductivity up to 400 W/m·K

Structural Material Enhancements:

-

Precision Heat Treatment: Controlled thermal processing for dimensional stability

-

Surface Engineering: PVD coatings and specialized treatments for wear resistance

-

Composite Integration: Hybrid metal-composite structures for optimized performance

-

Joining Technologies: Advanced welding and bonding for dissimilar materials

3. Precision CNC Machining Methodologies

3.1 Multi-Axis Machining for Complex Integration

The manufacturing of integrated actuator robot components requires advanced CNC machining capabilities to achieve the complex geometries and tight tolerances necessary for optimal system integration.

5-Axis Simultaneous Machining Applications:

-

Complex Internal Passages: Single-setup machining of cooling channels and wiring conduits

-

Integrated Mounting Features: Precision machining of sensor mounts and electronic compartments

-

Thin-Wall Structures: Manufacturing of lightweight sections with wall thickness down to 1.0mm

-

Multi-Material Components: Machining of hybrid structures with dissimilar materials

Critical Machining Parameters for Integrated Systems:

| Manufacturing Process | Material Type | Cutting Speed (m/min) | Feed Rate (mm/tooth) | Depth of Cut (mm) | Tolerance (mm) |

|---|---|---|---|---|---|

| High-Speed Milling | Aluminum 6061 | 800-1,200 | 0.08-0.20 | 0.5-3.0 | ±0.008 |

| Precision Boring | Steel 4140 | 100-180 | 0.03-0.10 | 0.2-1.0 | ±0.005 |

| Hard Machining | Hardened Steel | 80-120 | 0.02-0.06 | 0.1-0.4 | ±0.004 |

| Micro-Machining | Various | 200-400 | 0.005-0.020 | 0.05-0.20 | ±0.002 |

| Finish Machining | All Materials | Varies | 0.05-0.15 | 0.1-0.5 | ±0.010 |

3.2 Specialized Manufacturing Processes

Integrated Housing Manufacturing:

-

Multi-Function Cavities: Complex internal geometries for electronics and sensors

-

Cooling Channel Networks: Optimized fluid paths for maximum heat transfer

-

Cable Management Systems: Integrated conduits and strain relief features

-

Modular Interface Design: Precision mounting features for system integration

Electronics Integration:

-

Thermal Management: Direct cooling of power electronics components

-

EMI Shielding: Integrated shielding compartments and grounding features

-

Vibration Isolation: Strategic mounting systems for sensitive components

-

Connector Integration: Precision-machined connector interfaces and sealing systems

4. Thermal Management Engineering

4.1 Advanced Cooling System Design

Effective thermal management is critical in integrated actuator robot systems where power electronics and motors generate significant heat in compact spaces.

Cooling Technology Performance Analysis:

| Cooling Method | Heat Flux Capacity | Thermal Resistance | Volume Efficiency | Application Scope |

|---|---|---|---|---|

| Natural Convection | 0.5-1.0 W/cm² | 2.0-5.0 °C/W | Low | Light duty applications |

| Forced Air Cooling | 1.0-3.0 W/cm² | 0.8-2.0 °C/W | Medium | Standard industrial |

| Liquid Cooling | 5.0-20.0 W/cm² | 0.2-0.8 °C/W | High | High performance systems |

| Direct Cooling | 10.0-50.0 W/cm² | 0.1-0.4 °C/W | Very High | Power dense applications |

| Two-Phase Cooling | 20.0-100.0 W/cm² | 0.05-0.2 °C/W | Extreme | Maximum performance |

4.2 Integrated Thermal Solutions

Advanced Cooling Implementations:

-

Microchannel Cooling: High-aspect-ratio channels with hydraulic diameters 0.1-1.0mm

-

Embedded Heat Pipes: Two-phase cooling integrated within structural components

-

Direct Liquid Cooling: Coolant channels in direct contact with heat-generating components

-

Phase Change Materials: Thermal energy storage for peak power handling

5. Electronics Integration and Smart Features

5.1 Embedded Intelligence Systems

The integrated actuator robot incorporates sophisticated electronics that enable advanced functionality and system optimization.

Smart Feature Integration:

| System Feature | Implementation | Performance Benefit | Complexity Level |

|---|---|---|---|

| Condition Monitoring | Vibration, temperature sensors | Predictive maintenance | Medium |

| Self-Commissioning | Automated parameter identification | Reduced setup time | High |

| Adaptive Control | Real-time parameter adjustment | Optimized performance | Very High |

| Energy Optimization | Efficiency mapping | Reduced operating costs | Medium |

| Network Integration | Industrial protocols | System connectivity | Low |

5.2 Power Electronics Integration

Advanced Drive Systems:

-

High-Frequency Switching: PWM frequencies to 100 kHz for reduced torque ripple

-

Advanced Control Algorithms: Field-oriented control and torque vectoring

-

Efficiency Optimization: Loss minimization strategies across operating range

-

Protection Systems: Comprehensive fault detection and safe shutdown

6. Precision Assembly and System Integration

6.1 Controlled Assembly Processes

The assembly of integrated actuator robot systems requires meticulous process control and precision alignment to ensure optimal performance and reliability.

Critical Assembly Protocols:

-

Clean Room Assembly: Class 1000 environment for electronic and precision components

-

Precision Alignment: Laser alignment systems achieving <0.005mm positional accuracy

-

Thermal Management: Controlled application of thermal interface materials

-

Cable Integration: Precision routing and strain relief for all electrical connections

Assembly Quality Metrics:

-

Runout Tolerance: 0.006mm maximum for rotating assemblies

-

Parallelism: 0.008mm per 100mm for mounting surfaces

-

Concentricity: 0.005mm maximum between critical features

-

Flatness: 0.006mm per 100mm for interface surfaces

6.2 System Integration Excellence

Integration Verification:

-

Functional Testing: Comprehensive testing of all integrated systems

-

Performance Validation: Verification against specified performance parameters

-

Environmental Testing: Operation under specified environmental conditions

-

Lifecycle Testing: Accelerated testing for long-term reliability assessment

7. Quality Assurance and Testing Protocols

7.1 Comprehensive Metrology Systems

The verification of integrated actuator robot components employs state-of-the-art measurement technologies and rigorous inspection protocols.

Dimensional Metrology Capabilities:

-

Coordinate Measuring Machines: Volumetric accuracy 1.2 + L/400 μm with temperature compensation

-

Optical Scanning Systems: High-resolution 3D scanning for complex geometries

-

Roundness Measurement: Accuracy to 0.010μm with advanced analysis capabilities

-

Surface Topography: 3D surface analysis with Ra measurement to 0.005μm resolution

Performance Validation Testing:

-

Dynamic Response Analysis: Step response and frequency response characterization

-

Efficiency Mapping: Comprehensive power analysis across operating envelope

-

Thermal Performance: Infrared thermography and thermal resistance measurement

-

Vibration Analysis: Operational deflection shape analysis and modal testing

7.2 Environmental and Reliability Testing

Durability Validation Protocols:

-

Accelerated Life Testing: 20,000+ hours of continuous operation simulation

-

Thermal Cycling: -65°C to +150°C temperature extremes testing

-

Vibration Endurance: Random vibration to 20Grms per MIL-STD-810

-

IP Rating Certification: Comprehensive ingress protection testing per IEC 60529

Case Study Applications

Case Study 1: Collaborative Robotics Integration

Challenge: A robotics manufacturer needed compact integrated actuator robot systems for a new generation of collaborative robots requiring high torque density and built-in safety features in minimal space.

JLYPT Solution: We developed custom integrated actuator robot systems featuring advanced torque sensing and compact thermal management. The manufacturing process incorporated multi-axis machining for complex internal geometries and precision assembly for optimal performance.

Results:

-

Achieved torque density of 35 Nm/kg in compact form factor

-

Integrated safety torque monitoring with response time <2ms

-

Reduced system volume by 60% compared to traditional solutions

-

Enabled force control accuracy of ±0.5% full scale

Case Study 2: Aerospace Actuation Systems

Challenge: An aerospace manufacturer required integrated actuator robot systems for aircraft control surfaces with extreme reliability, wide temperature operation, and minimal maintenance requirements.

JLYPT Solution: Our team developed specialized integrated actuator robot systems using high-temperature materials and redundant systems architecture. All components underwent rigorous testing and qualification procedures.

Results:

-

Operated reliably from -55°C to +125°C ambient temperature

-

Achieved MTBF exceeding 100,000 hours in aerospace environment

-

Reduced maintenance requirements by 80% through integrated design

-

Met all DO-160 and MIL-STD-810 environmental requirements

Case Study 3: High-Speed Packaging Automation

Challenge: A packaging automation specialist required integrated actuator robot systems capable of 1,500 cycles per minute with precision positioning and minimal maintenance downtime.

JLYPT Solution: We implemented high-performance integrated actuator robot systems featuring advanced cooling and precision feedback systems. The design optimized dynamic response and thermal management for continuous high-speed operation.

Results:

-

Achieved operational speeds of 1,600 cycles per minute continuously

-

Maintained positioning accuracy within ±0.01° under full load

-

Extended service life to 30,000 hours between maintenance

-

Reduced energy consumption by 25% through efficiency optimization

Future Development Trends

Emerging Technologies and Innovations

The continued evolution of integrated actuator robot technology is driving advancements across multiple technical domains.

Advanced Material Applications:

-

Carbon Nanotube Composites: Revolutionary thermal and electrical properties

-

High-Temperature Superconductors: Transformative power density improvements

-

Smart Materials: Adaptive performance characteristics and self-monitoring capabilities

-

Metamaterials: Customized electromagnetic and thermal property engineering

Digital Integration Technologies:

-

Embedded AI Systems: On-device machine learning for adaptive control

-

5G Connectivity: Ultra-reliable low-latency communication for swarm robotics

-

Digital Twin Integration: Real-time virtual representation for performance optimization

-

Blockchain Security: Secure firmware validation and operational integrity

Conclusion: Engineering Excellence in Integrated Systems

Integrated actuator robot technology represents the pinnacle of mechatronic engineering in modern automation systems. The seven manufacturing techniques explored—system integration, advanced materials, precision machining, thermal management, electronics integration, assembly excellence, and comprehensive testing—demonstrate the holistic approach required to produce systems that meet the exacting demands of contemporary robotic applications.

As robotic technology continues to advance, the requirements for integrated actuator robot systems will become increasingly demanding, driving further innovation in manufacturing technologies and system integration. The convergence of digital technologies, advanced materials, and intelligent systems will ensure that integrated actuator technology remains at the forefront of industrial automation innovation.

At JLYPT, our commitment to manufacturing excellence ensures that every integrated actuator robot system we produce meets the highest standards of performance, reliability, and efficiency. Through continuous improvement and rigorous quality assurance, we enable our partners to achieve new levels of capability and performance in their automated systems.

For engineering teams seeking to enhance their robotic systems through superior integrated actuator solutions, contact JLYPT today to discuss your specific requirements and discover how our manufacturing expertise can contribute to your success in the competitive field of industrial automation.