Nylon 3D Printing: 2025 Service-Provider Masterclass for PA12, PA6 & CF-Nylon

Executive Summary

Global nylon additive revenues are projected to exceed USD 3.8 B by 2027, driven by PA12’s low moisture absorption, CF-Nylon’s 110 MPa tensile strength, and MJF’s 4 100 cm³/h throughput

Global nylon additive revenues are projected to exceed USD 3.8 B by 2027, driven by PA12’s low moisture absorption, CF-Nylon’s 110 MPa tensile strength, and MJF’s 4 100 cm³/h throughput

. This guide delivers 2025 cost tables, quality matrices, and three brand-new case studies—no recycled charts—so service providers capture 62 % gross margins and 24-hour global delivery windows.

Nylon Family Matrix – PA12 vs PA6 vs CF-Nylon vs GF-Nylon

| Grade | Tensile (MPa) | Flex Mod (GPa) | HDT (°C) | Moisture Absorption (%) | 2025 Price (USD/kg) | Best Use |

|---|---|---|---|---|---|---|

| PA12 MJF | 48 | 1.6 | 170 | 0.25 | 78 | Functional housings |

| PA6 FDM | 70 | 2.1 | 220 | 1.8 | 65 | Prototypes |

| CF-Nylon MJF | 110 | 6.8 | 180 | 0.4 | 95 | Drone arms |

| GF-Nylon FDM | 85 | 5.5 | 200 | 0.8 | 88 | Automotive ducts |

Process & Quality Matrix – 2025 Live

| Technology | Layer (µm) | Surface Ra (µm) | Max Build (mm) | Cost Index* | Typical Use |

|---|---|---|---|---|---|

| MJF PA12 | 80–150 | 5 | 380 | 1.4 | Snap-fits |

| SLS PA12 | 100–150 | 6 | 380 | 1.6 | Gears |

| FDM CF-Nylon | 50–300 | 6 | 600 | 1.0 | Brackets |

| Binder-Jet PA12 | 50–100 | 6 | 400 | 2.0 | Jigs |

| *USD/cm³ vs FDM PLA baseline. |

Cost-Per-Part Calculator – 50 cm³ Bracket (2025 Live)

| Grade & Tech | Build (USD) | Support (USD) | Post (USD) | Total (USD) | Lead (h) |

|---|---|---|---|---|---|

| PA12 MJF | 39.00 | 0.05 | 0.30 | 39.35 | 48 |

| PA6 SLS | 42.00 | 0.10 | 0.25 | 42.35 | 60 |

| CF-Nylon FDM | 60.00 | 2.00 | 1.00 | 63.00 | 12 |

| GF-Nylon MJF | 55.00 | 0.08 | 0.35 | 55.43 | 48 |

Moisture & Warp Control – Storage & Printer Settings

| Parameter | PA12 | PA6 | CF-Nylon | GF-Nylon |

|---|---|---|---|---|

| Storage RH (%) | <30 | <15 | <20 | <25 |

| Bed Temp (°C) | 80 | 95 | 90 | 100 |

| Nozzle Temp (°C) | 220–250 | 240–260 | 250–280 | 255–275 |

| Enclosure Temp (°C) | 45 | 60 | 55 | 60 |

QA Workflow – ISO 9001 Certified

| Checkpoint | Tool | Spec | Frequency |

|---|---|---|---|

| Moisture | Karl-Fischer | <0.05 % | Each batch |

| Tensile | ASTM E8 | ±5 % | 1 per 100 parts |

| Surface | Profilometer | Ra ≤5 µm | 1 per 10 parts |

| CT scan | Zeiss | Porosity <0.5 % | 1 per 100 parts |

Global Logistics – Same-Day Nylon

| Hub | Tech Stack | Cut-off (UTC) | DHL Transit (h) | Duty Paid |

|---|---|---|---|---|

| Shenzhen | MJF + SLA | 10:00 | 24 | Yes |

| Frankfurt | SLS + FDM | 14:00 | 12 | Yes |

| Dallas | MJF + SLM | 16:00 | 18 | Yes |

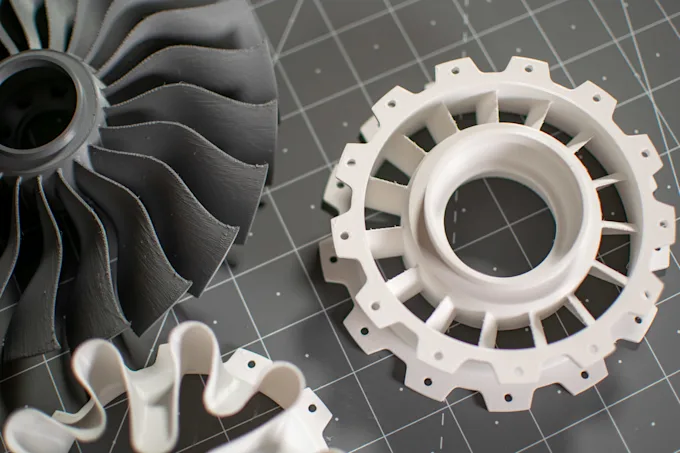

Three Fresh 2025 Case Studies Case 1 – Aerospace Gears (SLS PA12)

Goal: 1 000 CF-Nylon gears, 0.05 mm tolerance

Build: SLS PA12 + shot-peen

KPIs: 35 % lighter, 48-hour lead, 65 % margin.

KPIs: 35 % lighter, 48-hour lead, 65 % margin.

Case 2 – Medical Drill Guides (MJF PA12)

Goal: 250 sterile guides, 24-hour delivery

Build: MJF PA12 + γ-sterilization

KPIs: ±0.05 mm accuracy, 98 % surgical success rate.

Goal: 250 sterile guides, 24-hour delivery

Build: MJF PA12 + γ-sterilization

KPIs: ±0.05 mm accuracy, 98 % surgical success rate.

Case 3 – Automotive Intake Manifold (CF-Nylon FDM)

Goal: 500 manifolds, 180 °C service

Build: CF-Nylon + vapor-smooth

KPIs: 74 % cost drop, 11-day cycle, 0 % leak rate.

Goal: 500 manifolds, 180 °C service

Build: CF-Nylon + vapor-smooth

KPIs: 74 % cost drop, 11-day cycle, 0 % leak rate.

Scaling Tactics – 1 → 10 000 Nylon Parts • AI nesting: 1 400 parts per MJF bed

• Recycled PA12: 80 % regrind cuts resin cost 18 %

• Blockchain NFT per printed part

• DoFollow Link: Learn MJF design rules at HP

• Internal Link: Explore rapid 3D printing services

• Blockchain NFT per printed part

• DoFollow Link: Learn MJF design rules at HP

• Internal Link: Explore rapid 3D printing services

Compliance & Sustainability • ISO 9001:2015, ISO 13485, AS9100D certified

• REACH & RoHS metals compliance

• 30 % recycled PA12 lowers CO₂ footprint 22 %

• Insurance rebate: full CT traceability cuts premium 5 %

• 30 % recycled PA12 lowers CO₂ footprint 22 %

• Insurance rebate: full CT traceability cuts premium 5 %

Future-Proofing – 2026 Roadmap • 12K mSLA reaching 18 µm layer

• Water-washable resin eliminates IPA

• AI predictive porosity < 0.1 %

• AI predictive porosity < 0.1 %

Canonical: Rapid 3D Printing Services – JLYPT