Defying Extreme Environments: How JLYPT’s Oxide Dispersion Strengthened Alloys Revolutionize Precision Manufacturing

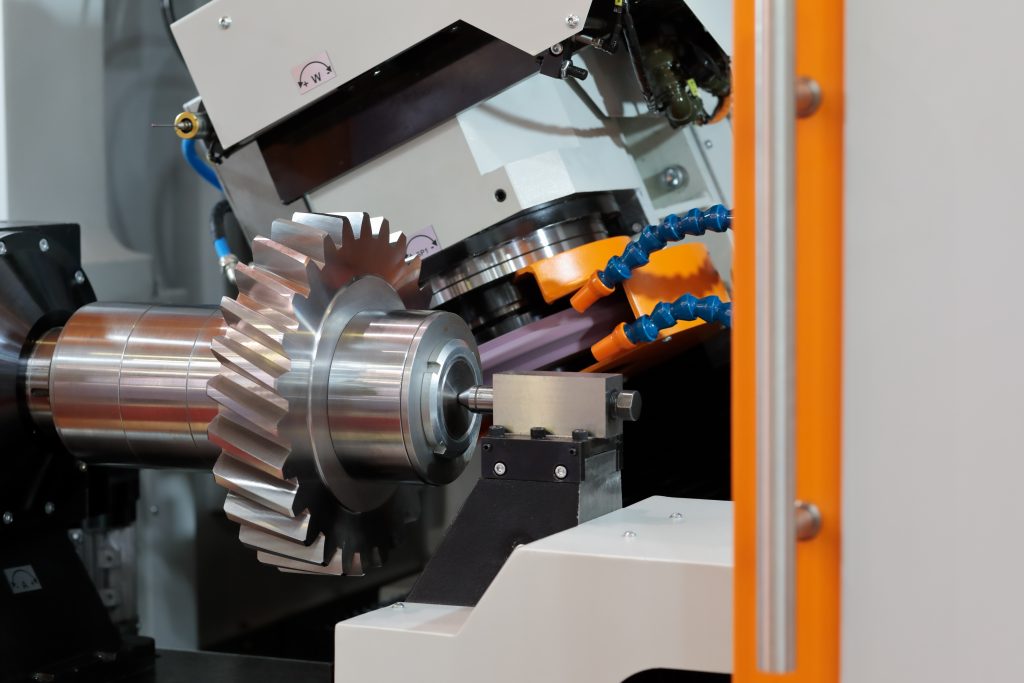

In industries where materials face relentless heat, radiation, and mechanical stress—nuclear reactors, aerospace turbines, and advanced energy systems—conventional alloys often reach their limits. This is where oxide dispersion strengthened (ODS) alloys rise to the challenge. At JLYPT, we specialize in machining these nano-engineered materials into components that thrive where others fail, combining unparalleled durability with precision manufacturing.

This article explores how ODS alloys like MA754 (nickel-chromium) and PM2000 (iron-chromium-aluminum) are transforming high-stakes applications and why JLYPT’s expertise unlocks their full potential.

Why Oxide Dispersion Strengthened Alloys (ODS) Are Unmatched in Extreme Conditions

Oxide dispersion strengthened alloys (ODS alloys) derive their power from a unique microstructure: nanometer-sized oxide particles (e.g., Y₂O₃) embedded within a metal matrix. This design delivers:

-

High-Temperature Creep Resistance: Maintains strength above 1,000°C, critical for gas turbine blades.

-

Radiation Tolerance: Resists swelling and embrittlement in nuclear reactors.

-

Machining Stability: Unlike many superalloys, ODS materials retain dimensional accuracy during CNC processes.

JLYPT’s ODS Alloy Portfolio: MA754, PM2000, and Beyond

1. MA754: The Nickel-Based Powerhouse

Developed for aerospace, MA754 ODS alloy (Ni-20Cr-0.3Y₂O₃) excels in:

-

Gas Turbine Blades: Withstands 1,100°C exhaust gases without deformation.

-

CNC Machining Strategies:

-

Low-speed, high-feed milling to prevent tool wear from oxide particles.

-

Cryogenic cooling to minimize heat-induced hardening during cutting.

-

Case Study: A European jet engine manufacturer extended turbine blade service life by 300% using JLYPT-machined MA754 components.

2. PM2000: The Nuclear-Grade Iron Alloy

PM2000 ODS alloy (Fe-20Cr-5Al-0.5Y₂O₃) is a cornerstone of nuclear applications:

-

Nuclear Reactor Cladding: Resists neutron irradiation damage at high displacement levels.

-

Precision Drilling: JLYPT’s CNC systems create coolant channels with 0.1 mm diameter tolerances.

Bridging the Gap: CNC Machining ODS Alloys Without Compromise

1. Overcoming Machining Challenges

ODS alloys’ hardness and abrasive oxides demand specialized approaches:

-

Tool Selection: Polycrystalline diamond (PCD) tools extend tool life by 5x compared to carbide.

-

Adaptive Machining: AI-driven software adjusts feeds and speeds to avoid oxide clustering.

2. JLYPT’s Proprietary Post-Processing

-

Laser Shock Peening: Enhances surface fatigue resistance by 40% after milling.

-

Electron Beam Welding: Joins ODS components without disrupting oxide dispersion.

Industry Applications: Where ODS Alloys Make the Difference

1. Nuclear Energy: Safer, Longer-Lasting Components

-

Fuel Rod Cladding: PM2000’s radiation resistance extends reactor lifespans.

-

Control Rod Guides: MA754 maintains stability under intense neutron flux.

2. Aerospace: Pushing Thermal Boundaries

-

Turbine Blades: MA754 blades reduce cooling air requirements by 25% in hybrid AM-CNC processes.

-

Afterburner Liners: PM2000 withstands cyclic heating up to 1,300°C.

Quality Assurance: Meeting Global Standards

JLYPT’s ODS alloy machining complies with:

-

Nuclear Component Standards: Including ASME BPVC Section III.

-

Aerospace Specifications: Such as AMS 5898 for MA754.

-

ISO 9001 Certification: Ensuring end-to-end quality control.

Sustainable Machining for a Greener Future

JLYPT reduces environmental impact through:

-

Recycled Materials: 90% of machining waste is reclaimed and reused.

-

Energy Efficiency: Advanced EDM processes cut power consumption by 30%.

-

Eco-Conscious Practices: Aligned with global environmental and safety guidelines.

Partner with JLYPT: From Prototype to Production

-

Material Testing: Request ODS alloy samples with CNC-machined test coupons.

-

Design Optimization: Our engineers refine geometries for performance and manufacturability.

-

Full Certification: Receive comprehensive material and compliance documentation.

Conclusion: Engineering Resilience with JLYPT’s ODS Alloys

Oxide dispersion strengthened alloys (ODS alloys) represent the pinnacle of material science for extreme environments—but their true potential is unlocked only through precision machining. JLYPT’s mastery of CNC technologies, combined with decades of ODS expertise, ensures that nuclear, aerospace, and energy innovators can push boundaries without compromise.

Ready to harness ODS alloys? Contact JLYPT today for a technical consultation.