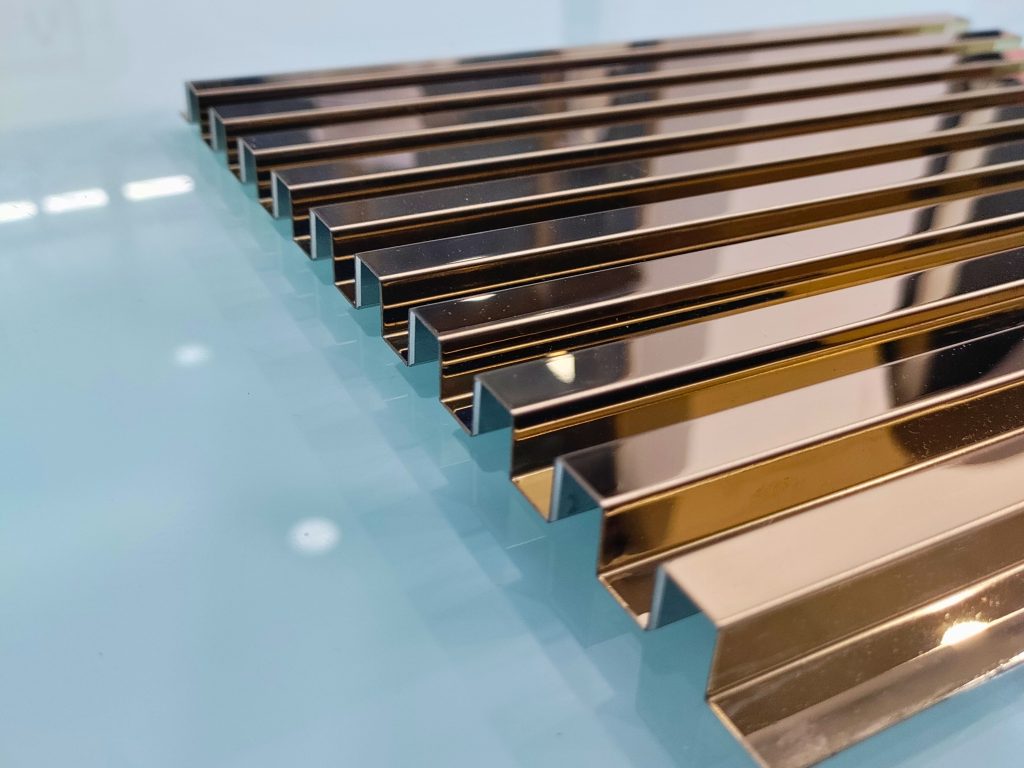

Advanced PVD Coating Services for Modern Industry

Technical Specifications of Our PVD Coating Services

Coating TypeMaterialsThicknessHardnessTemperature ResistanceKey ApplicationsWear ResistantTiN, CrN1-10μm1800-3500HV600°CCutting tools, moldsCorrosion ProofZrN, AlCrN2-8μm2000-2800HV800°CMarine componentsLow FrictionDLC, WS₂0.5-5μm1500-4000HV350°CBearings, gearsDecorativeTiN, ZrN0.3-3μm1500-2500HV400°CConsumer goodsThermal BarrierTiAlN3-15μm2500-3200HV1100°CEngine components

Industry-Specific PVD Coating Solutions

1. Automotive Applications

ComponentCoating SolutionPerformance BenefitTesting StandardPiston RingsCrN+DLC hybrid55% friction reductionASTM G133Transmission GearsTiAlN multilayer8x wear resistanceDIN 50324Fuel System PartsZrN nano-coating1000h salt spray resistanceISO 9227

2. Medical Device Coatings

| Device Type | Coating Material | Key Property | Compliance |

|-------------|------------------|--------------|------------|

| Surgical Tools | ZrN | Antimicrobial | ISO 10993 |

| Orthopedic Implants | TiO₂ | Osseointegration | FDA Class III |

| Dental Instruments | Au-based | Corrosion resistant | EN ISO 22674 |3. Aerospace & Defense

ApplicationCoating SystemSpecial RequirementsCertificationTurbine BladesTiAlN/AlCrN1100°C oxidation resistanceNADCAPSatellite ComponentsAlCrNUV/Vacuum stabilityESA ECSSFirearm ComponentsCrN500°C thermal cyclingMIL-STD-810

Three Detailed Case Studies

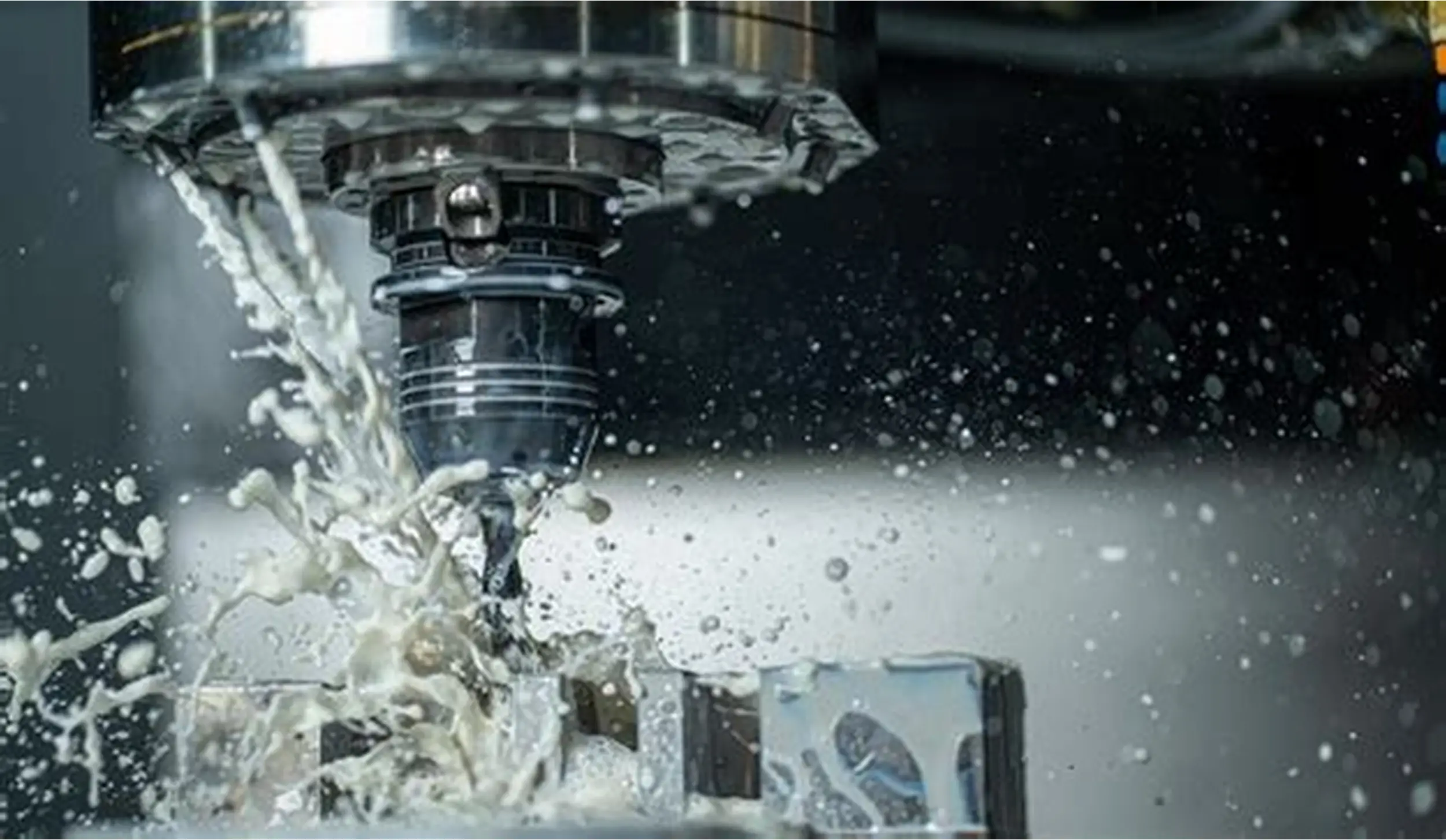

Case 1: High-Performance Cutting Tools

- Client: German automotive supplier

- Challenge: Needed to extend end mill lifespan in hardened steel machining

- Solution: Applied our proprietary TiAlN+WC/C multilayer coating

- Results: Achieved 7x tool life improvement, reduced machining costs by 40%

Case 2: Medical Implant Coating

- Client: US orthopedic manufacturer

- Challenge: Required biocompatible coating with 20-year durability

- Solution: Developed customized TiO₂/PEEK nanocomposite coating

- Results: Passed 5-year accelerated aging tests, FDA approval obtained

Case 3: Aerospace Component Protection

- Client: Asian satellite manufacturer

- Challenge: Needed UV-resistant coating for space applications

- Solution: Special AlCrN coating with graded architecture

- Results: Maintained performance through 10,000 thermal cycles

Our PVD Coating Process Flow

- Surface Preparation

- 3-stage ultrasonic cleaning

- Plasma etching (Ar+ bombardment)

- Substrate activation

- Coating Deposition

- High-power impulse magnetron sputtering (HIPIMS)

- Arc evaporation with macroparticle filtration

- Precise thickness control (±0.1μm)

- Quality Assurance

- Rockwell adhesion testing (HF1-HF6)

- Nanoindentation hardness measurement

- Optical emission spectroscopy analysis

For custom PVD coating solutions, contact our engineers at [email protected].