Introduction: The Critical Importance of Precision in Aluminum Machining

In the world of advanced manufacturing, tight tolerance CNC machining aluminum represents the pinnacle of precision engineering. While aluminum is often considered one of the more machinable metals, achieving and consistently holding tolerances within ±0.025mm (±0.001″) or finer demands specialized expertise, equipment, and processes. This level of precision is not merely a technical specification—it’s the fundamental requirement for components in industries where performance, safety, and reliability are non-negotiable. From the aerospace sector where lightweight aluminum structures must withstand tremendous forces, to the medical field where implantable devices require flawless biocompatibility, to optical systems where mounting surfaces must be perfectly flat to nanometer specifications, tight tolerance machining enables innovation across countless applications. This comprehensive guide explores the technical challenges, methodologies, and quality control processes that separate standard aluminum machining from true high-precision manufacturing. We’ll examine how advanced CNC strategies, temperature management, and metrology systems combine to produce aluminum components that meet the most demanding specifications. Furthermore, we’ll investigate the growing relationship between CNC machining and additive manufacturing, particularly how these technologies complement each other in the production of precision aluminum parts. Whether you’re designing a critical aerospace component, developing a sophisticated medical instrument, or engineering a high-performance automotive system, understanding the capabilities and limitations of tight tolerance aluminum machining is essential for success.

1. Understanding Aluminum Alloys for Precision Applications

Not all aluminum alloys are created equal when it comes to tight tolerance machining. The selection of the appropriate alloy is critical to achieving dimensional stability, desired mechanical properties, and surface finish requirements.

Wrought Aluminum Alloys:

-

6061-T6: Perhaps the most common precision machining alloy, offering an excellent balance of strength, corrosion resistance, and machinability. Its moderate strength (45 ksi yield) and good dimensional stability make it suitable for a wide range of applications from aerospace fittings to optical mounts.

-

7075-T6: Known for its high strength (73 ksi yield), comparable to many steels, this alloy is preferred for highly stressed aerospace components. However, its increased strength makes it more challenging to machine to tight tolerances due to greater cutting forces and potential for vibration.

-

2024-T3: Excellent fatigue resistance makes this alloy ideal for aerospace structural applications, though it’s less corrosion resistant than 6061 and requires protection in harsh environments.

-

6082: Similar to 6061 but with slightly different chemical composition, commonly used in European applications for structural components.

-

5052: Non-heat-treatable alloy with excellent corrosion resistance, often selected for marine applications and chemical processing equipment.

Cast Aluminum Alloys:

-

A356-T6: Commonly used for castings that will undergo secondary CNC machining to achieve final dimensions and tolerances. Good strength and casting characteristics.

-

383 (ADC12): Die casting alloy with excellent fluidity and minimal shrinkage, suitable for thin-walled components requiring subsequent precision machining.

Table: Aluminum Alloy Selection Guide for Precision Machining

| Alloy | Typical Applications | Machinability Rating | Dimensional Stability | Special Considerations |

|---|---|---|---|---|

| 6061-T6 | Aerospace fittings, optical mounts, structural components | Excellent (5/5) | Very Good | Best all-around choice for most precision applications |

| 7075-T6 | Aerospace spars, high-stress structural components | Good (4/5) | Good | Higher cutting forces require rigid setup |

| 2024-T3 | Aircraft structural members, truck wheels | Good (4/5) | Good | Poor corrosion resistance requires coating |

| 6082 | European automotive and structural applications | Excellent (5/5) | Very Good | Similar to 6061 with slight composition differences |

| 5052 | Marine hardware, chemical processing equipment | Fair (3/5) | Good | Non-heat-treatable, excellent corrosion resistance |

| A356-T6 | Cast housings with precision machined features | Good (4/5) | Very Good | Casting porosity may affect fine surface finishes |

The choice of aluminum alloy significantly impacts the achievable tolerances, surface finish quality, and overall manufacturing process. For instance, while 7075-T6 offers superior strength, its machining characteristics require more conservative cutting parameters to maintain tight tolerances compared to 6061-T6.

2. The Challenges of Maintaining Tight Tolerances in Aluminum

Despite aluminum’s reputation for machinability, holding tolerances below ±0.025mm (±0.001″) presents significant challenges that must be systematically addressed:

Thermal Management:

Aluminum has a relatively high coefficient of thermal expansion (23.1 μm/m·°C for 6061), meaning a 100mm long part will expand approximately 2.3μm for every 1°C temperature increase. During machining, heat generated at the cutting interface can cause localized expansion, leading to dimensional errors when the part returns to room temperature. Strategies to manage thermal effects include:

-

Using high-pressure coolant to maintain consistent workpiece temperature

-

Implementing temperature-controlled machining environments (±1°C)

-

Allowing parts to normalize to room temperature before final measurement

-

Using compensation algorithms in CNC programming based on thermal models

Tooling Selection and Management:

The wrong tooling approach can instantly compromise tolerance capabilities:

-

Tool Deflection: Even minimal deflection of end mills, particularly those with high length-to-diameter ratios, can result in tolerance violations. Using shorter, more rigid tools and conservative radial depths of cut is essential.

-

Tool Wear: Aluminum, while generally soft, can be abrasive to cutting tools, particularly with silicon-containing alloys. Progressive tool wear leads to gradual dimensional changes. Implementing tool wear monitoring and compensation is critical for long production runs.

-

Tool Geometry: Specific tool geometries optimized for aluminum—with sharp cutting edges, high helix angles, and polished flutes—reduce cutting forces and improve dimensional control.

Workholding and Distortion:

The forces exerted by workholding fixtures can cause elastic deformation of aluminum parts, which is released after machining, altering dimensions. This is particularly problematic for thin-walled structures. Solutions include:

-

Using vacuum fixtures for uniform clamping pressure across large surface areas

-

Implementing sequential machining strategies that maintain structural integrity until final operations

-

Designing custom fixtures that support the part at critical locations to minimize distortion

-

Using low-viscosity hydrostatic fixtures for complex geometries

Machining Strategy:

The CNC programming approach significantly impacts tolerance achievement:

-

Climb vs. Conventional Milling: Climb milling (down milling) generally provides better dimensional control and surface finish in aluminum

-

Toolpath Optimization: Modern toolpath strategies like trochoidal milling and adaptive clearing maintain consistent chip loads and reduce tool deflection

-

Finishing Sequences: Implementing multiple spring passes allows the tool to remove material elastically springing back after initial cutting

-

Non-contact Measurement: On-machine probing allows for in-process verification and compensation without removing the part from the fixture

3. CNC Technologies for Ultra-Precise Aluminum Machining

Achieving tight tolerances in aluminum requires more than just standard CNC equipment. Several advanced technologies are essential for consistent results:

High-Speed Machining (HSM) Centers:

Modern HSM centers designed for aluminum feature:

-

Spindle speeds of 20,000-60,000 RPM for fine surface finishes and precise material removal

-

Rapid traverse rates exceeding 40m/min for reduced non-cutting time

-

Advanced linear motor technology for exceptional positioning accuracy and repeatability

-

Thermal stability systems that compensate for heat generated by spindles and drives

-

Vibration-damping cast iron constructions and isolated foundations

5-Axis Simultaneous Machining:

While 3-axis machining is sufficient for many applications, 5-axis capability offers distinct advantages for tight tolerance work:

-

Single Setup Accuracy: Complex parts can be completed in one setup, eliminating cumulative errors from multiple fixturings

-

Optimal Tool Orientation: The tool can be maintained normal to the surface being machined, ensuring ideal cutting conditions and geometry accuracy

-

Short Tool Usage: 5-axis positioning allows the use of shorter, more rigid tools, minimizing deflection

-

Complex Geometry: Capability to machine intricate features that would be impossible with 3-axis approaches

On-Machine Probing and Metrology:

Integrated probing systems transform CNC machines into measurement devices:

-

Tool Setting Probes: Automatically measure tool length and diameter offsets after each tool change

-

Workpiece Probes: Verify part location, orientation, and feature geometry without removing from the machine

-

Laser Tool Setting: Non-contact measurement of tool geometry with micron-level accuracy

-

Adaptive Machining: Measurement data can feed back to the CNC controller to automatically adjust tool paths for compensation

Advanced Coolant Systems:

Temperature management is critical for dimensional stability:

-

High-Pressure Coolant (1000+ psi): Effectively evacuates chips and reduces cutting zone temperature

-

Through-Tool Coolant: Delivers coolant directly to the cutting edge for maximum effectiveness

-

Temperature-Controlled Coolant: Maintains coolant at precisely 20°C to stabilize workpiece temperature

-

Minimum Quantity Lubrication (MQL): For certain operations where flood coolant might cause thermal instability

Table: Tolerance Capabilities Based on Machining Approach

| Machining Approach | Typical Tolerance Capability | Surface Finish (Ra) | Best Applications |

|---|---|---|---|

| Standard 3-Axis | ±0.05mm (±0.002″) | 0.8-1.6μm | General purpose components, non-critical features |

| High-Speed 3-Axis | ±0.025mm (±0.001″) | 0.4-0.8μm | Precision components, optical mounts, mechanical assemblies |

| 5-Axis Positioning | ±0.015mm (±0.0006″) | 0.2-0.4μm | Complex geometries requiring multiple setups |

| 5-Axis Simultaneous | ±0.010mm (±0.0004″) | 0.1-0.2μm | Aerospace structures, complex organic shapes |

| Ultra-Precision Machining | ±0.0025mm (±0.0001″) | <0.05μm | Optical components, micron-level precision parts |

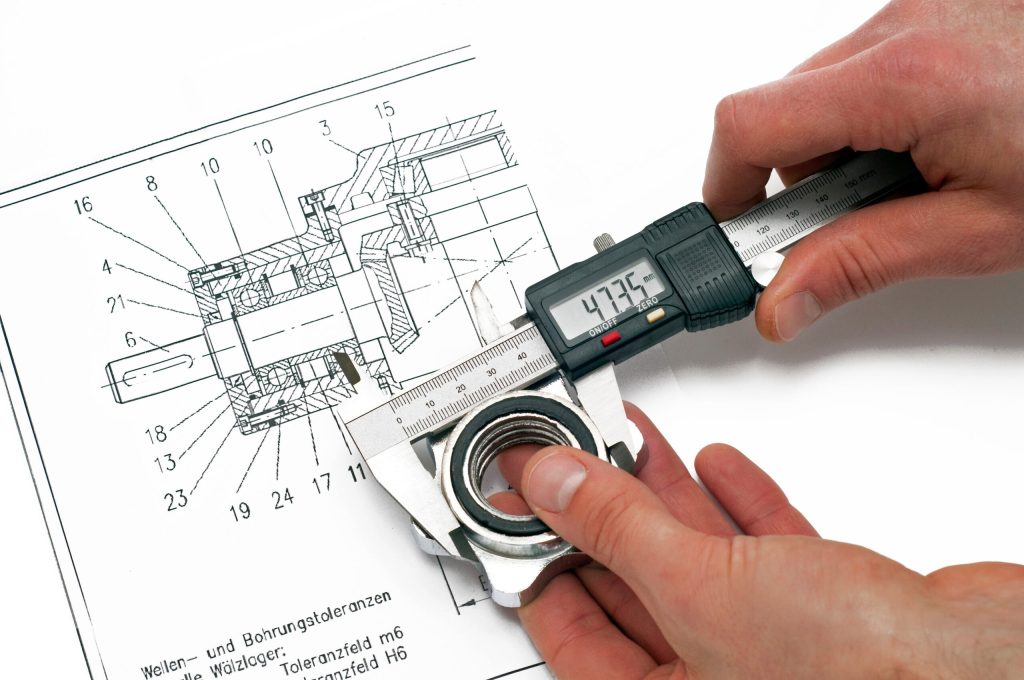

4. Quality Assurance and Metrology for Precision Aluminum Parts

Verifying that machined aluminum components meet specified tolerances requires sophisticated measurement equipment and methodologies:

Coordinate Measuring Machines (CMM):

Modern CMMs with scanning capabilities provide comprehensive dimensional analysis:

-

Volumetric Accuracy: Compensation for machine geometric errors across the entire working volume

-

Scanning Probes: Continuous data collection for complete surface profile analysis

-

Temperature Compensation: Environmental controls to account for thermal expansion during measurement

-

CAD Comparison: Direct comparison of measured data to original CAD models with color deviation maps

Optical Measurement Systems:

For features difficult to measure with tactile probes:

-

Vision Systems: Automated 2D measurement with sub-micron resolution

-

Laser Scanners: Non-contact 3D scanning for complex surface analysis

-

White Light Interferometry: Nanometer-level surface topography measurement

Surface Finish Analysis:

-

Contact Profilometers: Stylus-based measurement of surface roughness parameters (Ra, Rz, Rq)

-

Optical Profilometers: Non-contact measurement for delicate surfaces

Statistical Process Control (SPC):

Implementing SPC methodology ensures consistent quality:

-

Control Charts: Monitoring of critical dimensions over time to detect process trends

-

Process Capability Analysis: Calculating Cp, Cpk values to quantify process performance relative to specifications

-

Gage R&R Studies: Quantifying measurement system variability

First Article Inspection (FAI):

Comprehensive verification of initial production parts against all design requirements:

-

AS9102 Compliance: Standardized reporting for aerospace applications

-

Full Dimension Verification: Every specified characteristic measured and documented

-

Material Certification: Verification of alloy composition and properties

5. Case Studies: Tight Tolerance Aluminum Machining in Practice

Case Study 1: Aerospace Satellite Mounting Structure

-

Challenge: Machine a large (600mm × 400mm × 50mm) 6061-T6 aluminum mounting platform with 74 precision bore holes positioned within ±0.015mm true position and a flatness requirement of 0.025mm across the entire surface. The part would experience significant thermal cycling in space environment.

-

Solution: The part was machined on a 5-axis machining center with integrated thermal compensation. A specialized vacuum fixture was designed to hold the part without inducing stress. The machining process was conducted in a temperature-controlled environment (±1°C). Each machining operation was followed by a thermal equalization period. On-machine probing verified feature locations between operations, with the CNC program automatically applying compensation offsets.

-

Result: All 74 bore holes met true position tolerance, and the surface flatness measured 0.020mm across the entire platform. The part passed rigorous thermal cycling tests with no dimensional degradation.

Case Study 2: Medical Imaging Device Component

-

Challenge: Produce an intricate aluminum housing for an MRI component with wall thicknesses as low as 0.3mm, dimensional tolerances of ±0.010mm, and an internal labyrinth cooling channel network with cross-sectional dimensions held to ±0.025mm.

-

Solution: The component was manufactured using a hybrid approach. The internal cooling channels were produced using laser powder bed fusion (L-PBF) additive manufacturing, which enabled the complex internal geometry that would be impossible with conventional machining. The additively manufactured preform was then stress-relieved and precision machined on a 5-axis micro-machining center to achieve the critical external dimensions and mating features. Specialized micro-tools (0.2mm diameter) were used for the thin-wall sections.

-

Result: The hybrid manufacturing approach successfully produced the component with all dimensions within specification. The internal cooling channels performed with 15% better efficiency than previous designs, while the external precision features maintained the required tolerances for proper assembly and function.

Case Study 3: High-Performance Automotive Transmission Housing

-

Challenge: Machine a 7075-T6 aluminum transmission housing with bearing bore diameters held to IT6 tolerance grade (±0.008mm) and surface finish of Ra 0.2μm. The housing needed to maintain dimensional stability under high operational loads and temperatures.

-

Solution: The housing was machined using a multi-process approach. Roughing was performed on a high-torque machining center to remove bulk material efficiently. Semi-finishing operations established critical datums. Final boring operations used precision boring heads with continuous diameter adjustment capability. The finishing process employed balanced ceramic boring bars to minimize vibration. Each housing underwent a cryogenic stabilization process after machining to relieve residual stresses before final honing to size.

-

Result: All bearing bores were held within IT6 tolerance with surface finishes averaging Ra 0.18μm. The transmission housings demonstrated exceptional dimensional stability during performance testing, contributing to a 20% increase in power density over previous designs.

6. The Synergy Between CNC Machining and Additive Manufacturing for Aluminum Components

The manufacturing landscape is evolving toward integrated approaches that leverage the strengths of both subtractive and additive processes:

Hybrid Manufacturing:

Combining additive manufacturing for complex geometries with CNC machining for precision features offers compelling advantages:

-

Design Freedom: AM creates complex internal channels, lattices, and organic shapes

-

Material Efficiency: Near-net-shape preforms minimize material waste

-

Precision Finishing: CNC machining provides critical tolerances and surface finishes

-

Consolidated Assemblies: Multiple components can be combined into single structures

Additive Manufacturing Processes for Aluminum:

-

Laser Powder Bed Fusion (L-PBF): The most common process for aluminum components, using a laser to selectively fuse fine aluminum powder layers

-

Binder Jetting: A lower-temperature process that bonds powder with a binder, later sintered to full density

-

Directed Energy Deposition (DED): For adding material to existing components or repairing high-value parts

Post-Processing Requirements:

Additively manufactured aluminum components require significant post-processing before achieving precision tolerances:

-

Stress Relief: Thermal treatment to reduce residual stresses from the additive process

-

Hot Isostatic Pressing (HIP): For reducing internal porosity and improving mechanical properties

-

CNC Machining: Essential for achieving dimensional accuracy and surface finish on critical features

Design Considerations for Hybrid Aluminum Parts:

-

Stock Allowance: Typically 0.5-2.0mm additional material on features requiring machining

-

Orientation: Additive build orientation affects both machining requirements and mechanical properties

-

Support Structures: AM requires supports for overhanging features, which must be removed before machining

-

Datums: Planning for machined datums early in the design process

Conclusion: Achieving Precision Excellence in Aluminum Machining

Tight tolerance CNC machining of aluminum represents a sophisticated intersection of materials science, advanced manufacturing technology, and metrology. While aluminum is often perceived as an easy-to-machine material, achieving and consistently holding tolerances below ±0.025mm demands specialized expertise, equipment, and processes. The applications for such precision—from aerospace and defense to medical devices and advanced optics—continue to grow as technology advances across all sectors.

The future of precision aluminum machining points toward even greater integration of technologies. Hybrid manufacturing cells that combine additive and subtractive processes in a single environment will enable the production of components with unprecedented complexity and precision. Artificial intelligence and machine learning algorithms will further optimize machining parameters in real-time, adapting to tool wear, material variations, and thermal conditions to maintain tolerances throughout production runs. Advanced metrology systems with in-line measurement capabilities will provide closed-loop feedback for continuous process improvement.

At JL YPT, we understand that precision is not just about meeting specifications—it’s about building trust with our customers who depend on our components to perform flawlessly in critical applications. Our investment in advanced CNC technology, temperature-controlled manufacturing environments, and comprehensive metrology capabilities reflects our commitment to precision excellence.

Ready to discuss your precision aluminum machining project? Contact JLYPT today to leverage our expertise in tight tolerance manufacturing for your most demanding applications.